Structure diagram of rotary separator for coal mill

.jpg)

Structure diagram of coal mill and separator

Download scientific diagram Structure diagram of coal mill and separator from publication: Onedimensional mathematical model of coal combustion in furnace and its2018年11月5日 In this paper, the influence of the structural parameters of the rotary separator on the separation performance is studied by the analysis software FLUENT The structural Optimization of structural parameters of rotary separatorThe invention relates to a coal powder separator, in particular to an adjustable dynamic rotary separator for a coal mill The adjustable dynamic rotary separator is characterizedCNA Adjustable dynamic rotary separator for coal mill Raw coal is transported on a conveyor belt and dropped into the mill through the chute The coal falls into the grinding table rotating at a constant speed The coal then moves under centrifugal (PDF) Modeling and Control of Coal Mill Academia

Figure 1 Structure diagram Figure 2 Rotating

In this paper, the influence of the structural parameters of the rotary separator on the separation performance is studied by the analysis software FLUEN rotary separator isAbstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the Modeling and Control of Coal MillVertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materials2014年3月1日 The operation parameters were adjusted for analyzing the breakage and separation characteristics in the industrial mill under the normal working condition The Breakage and separation mechanism of ZGM coal mill based on

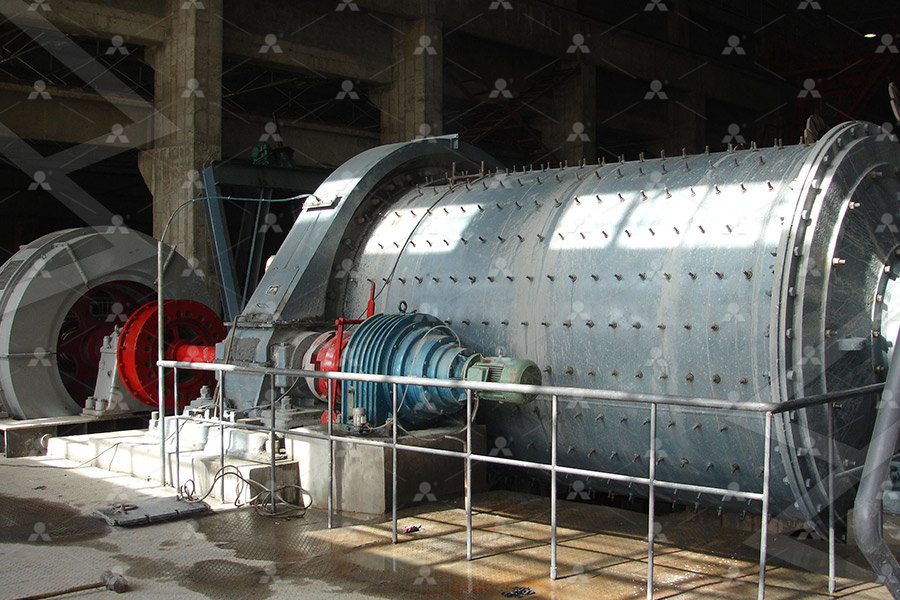

COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

The hot air from the hot stove or waste gas of cement production line are exhausted into coal vertical mill by fans, exchange heat with raw coal in mill, and then take pulverized coal up to It can be divided into vertical roller mill, horizontal cylinder roller mill, high pressure roller mill, Raymond mill, and column mill The basic structure of the vertical roller mill with vertical Roller Mill SpringerDownload scientific diagram Illustration of the rotary triboelectrostatic separator from publication: Dry Cleaning of Pulverized Coal Using a Novel Rotary Triboelectrostatic Separator (RTS Illustration of the rotary triboelectrostatic separator2023年7月4日 The basic structure of the roller mill includes the grinding roller, Structure diagram of Raymond mill Full size image The Raymond mill is mainly used to grind coal, nonmetallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, and other materials The product particle size is 0045–0125 mmRoller Mill SpringerLink

.jpg)

An investigation of performance characteristics and

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS2014年1月1日 A commercial system consisting of a series of five winnowing columns was developed and installed at a local palm oil mill The 5% for a rotary separator for the dry coal preparation A Rotary Separator for the Dry Mixture of Palm Kernel and ShellDynamic Separator for Coal Mill Productivity: 10–60 t/h Motor power: 15–90 kw Air quantity: 21000– m3 Application range: coal, ore, etcDynamic Separator for Coal Mill HXJQ Machinery

.jpg)

Modeling and Control of Coal Mill

Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validationIt contains coal feeder, coal mill, rotary separator, raw coal hopper and stone coal scuttle, as depicted in Fig 2 The coal pulverizing system grinds the raw coal into pulverized coal with Schematic diagram of the coal pulverizing systemthe mill such as rotary feeder or directive The supplier had to issue an ATEX declaration of conformity The documents submitted in connection with the coal mill in Lixhe were checked and certified by the TÜV Rhineland technical inspection authority Plant layout Figure 3 shows the plant process diagram The coal is fed into the MPS 225 COAL GRINDING IMPS: more than meets the eye Gebr PfeifferThe document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal Mill

Cement Separator HighEfficiency Cement Mill

Rotary Separator: The rotary separator is a common model of Cement Mill separators that uses centrifugal force to separate cement powder and gas The rotary separator is suitable for mediumsized production lines, and its main 2014年1月1日 The emission factors of kiln end, kiln head, coal mill, crushing and cement mill was 0156 clinker g/t, 3914 clinker g/t, 1538 coal g/t, 0016 stone g/t and 0056 cement g/t respectively, the (PDF) MPS mills for coal grinding ResearchGateOne of the best energy recovery options is using kiln offgas for coal mill hot gas as evaluated in Table 3 Coal mill requires 77620 Nm3/h (90670 kg/h) hot gas with temperature 248 oC to heating raw coal Currently, about 80% coal mill offgas (72700 Nm3/h) recirculated to coal mill inlet and burner system to minimize fuel consumptionStudy of rotary kiln offgas energy recovery for coal mill hot gasDownload scientific diagram Structure diagram of the rotary drilling rig from publication: Transient Analysis of Rotary Drilling Rig in Response to Sudden Breaking of Wire Rope for Drilling Structure diagram of the rotary drilling rig

.jpg)

Schematic diagram of coal pulverizing system

As depicted in Fig 3, it contains coal feeder, coal mill, rotary separator, raw coal hopper and stone coal scuttle In practical systems, the types of coal and unit load would change frequently Experimental system Fig 3 shows the structure of our rotary triboelectrostatic sepa ration (RTS) system, which consists of the feeding device, rotary charging device, separation chamber, and Separation system diagram of RTS Download Scientific Diagram2024年3月7日 Experts have carried out detailed research on the separator structure Johansson and Evertsson 2 studied the factors affecting the performance of the separator by CFD simulation, including the mechanical structure, the airflow velocity and turbulence, and the particle shape and size Guizani et al 3,4 studied the influence of separator structure on particle motion and flow Simulation study on rotor speed of combined rotary separator in coal 2019年3月29日 Furthermore, utilization of kiln offgas as hot gas coal mill was studied to replace existing recirculation system of coal mill offgas Energy recovery of 142 GJ/hour can be achieved with additional environmental benefit from 803% reduction in consumption of fossil fuel for coal mill hot gas generationStudy of rotary kiln offgas energy recovery for coal mill hot gas

.jpg)

sbm/sbm diagram for zgm113n coal millmd at main dihog/sbm

sbm diagram for zgm113n coal millzgm95 type roller mill size Beijing Power Plant Vertical Mill DescriptionAtox coal mill 200 300 1500 3000 100 200 45 60 ms small size big energy savings 2 proven technology today the airswept vertical roller mill is the standard solution for coal grinding installations and thanks to our continuous refinement of the atox coal mill over the years Rotary separator in flour mill processing has the advantages of reasonable design, simple structure, stable operation, fully enclosed structure, no dust, no antiblocking, antiadhesive net, and so on In particular, the screening effect of materials with strong hygroscopicity, high viscosity, easy plugging, and sticking is more obviousNews Rotary separator in flour mill processingWhat Is Air Swept Coal Mill The airswept coal mill is also called a coal grinder It is the main equipment of the cement plant, used for drying and pulverizing coal powderIt mainly consists of the feeding device, main bearing, rotary part, Air Swept Coal Mill Coal Mill In Cement Plant2020年4月7日 present, this type of mill has been widely used in coalfired power plants of China, and its structure is shown in Figure 1 The mediumspeed coal mill system is mainly composed of ra w coal bunker,Modeling of Coal Mill System Used for Fault

.jpg)

Coal Pulverizers an overview ScienceDirect Topics

An introduction to the nature of coal J Groppo, in Coal Combustion Products (CCP's), 2017 14 Coal pulverizing In general, coal is transported and stored as fuel for use at as coarse a size as possible in order to minimize losses during handling and transport, moisture absorption, and spontaneous combustion, among other considerations2024年3月1日 Simulation study on rotor speed of combined rotary separator in coal pneumatic conveying March 2024; AIP Advances 14(3) DOI:101063/5 pact structure, environmental protection, and high Simulation study on rotor speed of combined rotary separator in coal 2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Modeling and Parameter Identification of Coal Mill2015年11月1日 The coal mill grinds the raw coal into fine powder and hot air entering the mill dries and carries the pulverized coal to the burners of the furnace Maffezzoni (1986 ) emphasized that coal mills are the primary cause of slow load following capability and regular plant shutdownsA unified thermomechanical model for coal mill operation

.jpg)

Pemanfaatan Gas Buang Rotary Kiln sebagai Gas Panas Coal Mill

Rotary kiln adalah salah satu peralatan yang paling banyak mengkonsumsi energi pada proses pirometalurgi industri pengolahan nikel Dalam penelitian ini pemanfaatan energi dari gas buang rotary kiln dikaji untuk proses pemanasan batubara di peralatan coal mill Analisa massa dan aliran energi dikembangkan berdasarkan hukum konservasi aliran massa dan energi yang 2022年2月24日 Curves of mill productivity, power consumed, specific surface of coal dust in terms of the relative rotational speed of the ball drum mill Composition of the balls loading the mill with a standard Improving the efficiency of the coal grinding process in ball drum 2015年5月13日 We mainly provide oversize block separator, coal vibrating screener, damper and valve for FGD and GGH system, belt conveyor carrier roller adjuster Our products are suitable for mining and agriculture industry, of which the belt conveyor carrier roller adjuster is used on any industry that has belt conveyorRotary Oversize Coal Separator China Coal Mining and Thermal 2023年6月30日 A coalfired heating rotary dryer is a standard industrial drying equipment mainly used for heat treatment and highhumidity drying materials The coalfired rotary dryer working principle is to evaporate the moisture in the material and dry it through the thermal energy generated by burning coal The rotary dryer can dry coal, slag feed, biomass fuel, slag ore, CoalFired Heating Rotary Dryer System JXSC Machine

Illustration of the rotary triboelectrostatic separator

Download scientific diagram Illustration of the rotary triboelectrostatic separator from publication: Dry Cleaning of Pulverized Coal Using a Novel Rotary Triboelectrostatic Separator (RTS 2023年7月4日 The basic structure of the roller mill includes the grinding roller, Structure diagram of Raymond mill Full size image The Raymond mill is mainly used to grind coal, nonmetallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, and other materials The product particle size is 0045–0125 mmRoller Mill SpringerLink2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS

A Rotary Separator for the Dry Mixture of Palm Kernel and Shell

2014年1月1日 A commercial system consisting of a series of five winnowing columns was developed and installed at a local palm oil mill The 5% for a rotary separator for the dry coal preparation Dynamic Separator for Coal Mill Productivity: 10–60 t/h Motor power: 15–90 kw Air quantity: 21000– m3 Application range: coal, ore, etcDynamic Separator for Coal Mill HXJQ MachineryAbstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validationModeling and Control of Coal MillIt contains coal feeder, coal mill, rotary separator, raw coal hopper and stone coal scuttle, as depicted in Fig 2 The coal pulverizing system grinds the raw coal into pulverized coal with Schematic diagram of the coal pulverizing system

COAL GRINDING IMPS: more than meets the eye Gebr Pfeiffer

the mill such as rotary feeder or directive The supplier had to issue an ATEX declaration of conformity The documents submitted in connection with the coal mill in Lixhe were checked and certified by the TÜV Rhineland technical inspection authority Plant layout Figure 3 shows the plant process diagram The coal is fed into the MPS 225 The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal Mill