Limestone crushing 46 crushing calcite raw Production

Limestone Crushing Process JXSC Mineral

The limestone crushing process involves several stages, each with specific machinery and equipment The typical limestone crushing process is Primary Crushing > Secondary Crushing > Screening > Conveying > StorageChemical limestone forms when calcium and carbonate ions suspended in water chemically bond and precipitate from their aquatic sources Because of its high calcium content, limestone is Limestone Quarrying and Processing: A LifeCycle InventoryCalcium carbonate deposited in lakes and seas is compacted and cemented after losing water, called limestone The mineral composition of limestone is mainly calcite (accounting for more than 50%) and some impurities such as clay and Limestone Aggregate Crushing JXSC Machine2007年12月21日 Lime industry production starts by quarrying and crushing highgrade carbonate rocks sourced from carefully chosen deposits with welldefined geological features, Lime and Limestone: Chemistry and Technology, Production and

PRODUCTION OF PRECIPITATED CALCIUM CARBONATE (PCC)

y local limestone is used as a starting material and needs to be prepared involving 3 main processes which are calcinations, slaking and recarbonation The uniqueness of the tall 2023年2月13日 The production capacity and efficiency of the limestone crushing equipment will depend on several factors, including the type of equipment, the material properties, and the capacity You should carefully consider the production capacity and efficiency of the equipment they are considering to ensure it meets their needsWhat Is The Best Limestone Crusher Limestone Crushing AGICO2023年2月14日 In conclusion, the limestone crushing process is a crucial step in the production of cement and other industries that utilize limestone as a raw material The quality of the final product depends on several factors, including Optimized Limestone Crushing Process for Increased 2007年12月21日 When the choice of the raw material falls on marly limestone composed of 6520 wt% clays, the production process is obviously characterized by different temperatures and times and the finished Lime and Limestone: Chemistry and Technology, Production and

Limestone Aggregate Crushing JXSC Machine

1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the The calcite crusher can produce the raw materials in different Mosh hard with continuous performance The common calcite crushers are jaw crusher, cone crusher, impact crusher etc In the calcite crushing plant, the runofmine calcite is fed into jaw crusher for primary crushing, and then the crushed calcite is transferred to secondary crusher Calcite Ore Crushing Solutions DSMAC2024年5月23日 During cement production, calcite acts as a fluxing agent, lowering the melting temperature of raw materials, thereby conserving energy and enhancing production efficiency These functions of calcite collectively ensure the performance and quality of cement products, meeting the construction industry's demand for highperformance cementCalcite: A Key Ingredient in Efficient Cement Manufacturing2018年7月3日 Request PDF Industrial Production of Limestone Calcined Clay Cement (LC 3 ) – Experience and Insights The reduction of the clinker factor in cement has emerged as the most promising solution Industrial Production of Limestone Calcined Clay Cement (LC 3

.jpg)

Limestone crushing and screening production line introduction

2024年1月23日 Cement Production: Crucial raw material in cement preparation, obtained through the calcination process to produce quicklime Chemical Industry: Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feeder2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage2022年8月29日 Production line advantage 1 High degree of automation The entire production line requires almost no manual operations except for equipment startup, suspension and routine maintenance The production line has simple process, high production efficiency, large output and low operating costDolomite crushing and sand making production lineRaw Bauxite Crushing Process: Bauxite ore in larger size will be fed into the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing After primary crushing, the material will transferred to impact crusher Bauxite Crushing Plant Shanghai Zenith Company

.jpg)

PRODUCTION OF PRECIPITATED CALCIUM CARBONATE (PCC)

25 XRD spectra of the synthetically prepared calcite, aragonite and vaterite 44 31 Flow chart of PCC production 47 32 (a) the large limestone (b) the crushed limestone in the size range 49 1020mm in diameter is ready for calcinationsThe limestone crushing production line typically includes several components: 1 Feeder: The feeder is the first step in the limestone crushing production line It is used to feed raw limestone into the crusher at a controlled rate This ensures a steady supply of material to the crushing equipment 2 Crusher: The crusher is the main component Limestone crushing production line NEWS SMMVIK MachineryLimestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin as is the case with travertineLimestone Quarrying and Processing: A LifeCycle InventoryAggregate crushing plants are used in the production of raw materials in many industries and these crushing plants are the backbone of industrial sector First of all, it will be much more helpful to explain what is Aggregate and this will give more advantage to Aggregate Crushing Plants GENERAL MAKINA

.jpg)

Limestone Stone Crushing Plant Shanghai Zenith Company

Limestone Crushing Process: Passing through a hopper, raw limestone materials are fed by vibrating feeder into the jaw crusher evenly and gradually for primary crushing After first crushing, the material will be transferred by belt conveyor to impact crusher for secondary crushing2017年7月7日 Limestone is also a very important industrial mineral Its chemical properties make it a valuable mineral for a wide range of industrial/manufacturing uses Limestone is also one of the vital raw materials used in production of iron and steel Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weightLimestone – Its Processing and Application in Iron and2010年3月29日 PDF Limestones in Cyprus are mainly quarried for the production of coarse and fine aggregates to be used in concrete The objective of this paper is Find, read and cite all the research you (PDF) Crushed limestone as an aggregate in concrete production: The So far as India, the secondlargest producer of cement, is concerned, the mineral production statistics of the Indian Bureau of Mines (7), the apex body dealing with mines and minerals in the country, showed that the production of limestone from April, 2014 to March, 2015 was 293 million metric tons, although the total cementgrade limestone resources in the country were about Basics of mineral resources for cement production

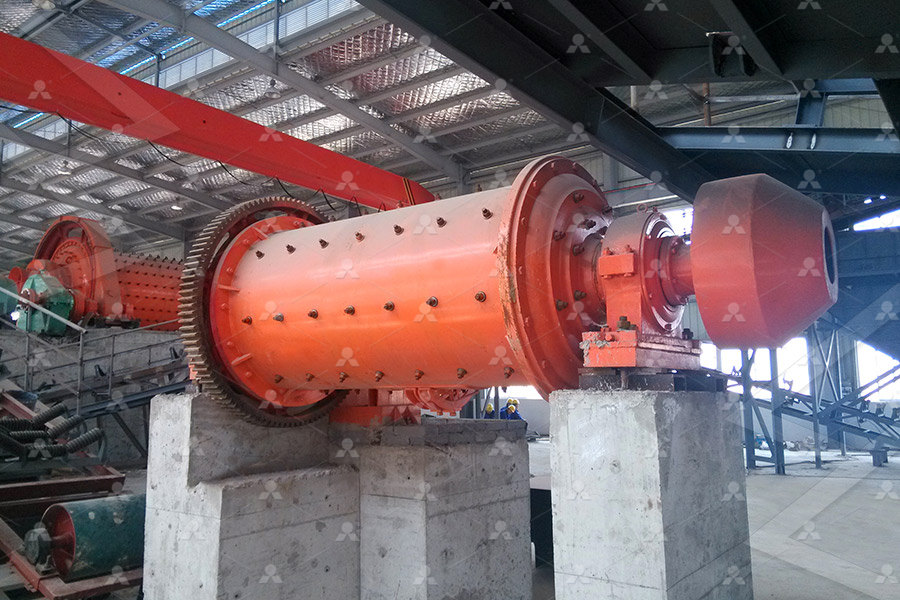

Limestone Crushing Equipment and Production Line

Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcProduction data are incomplete, because of the limited scale of the industry However, output has typically been a few thousand tonnes a year and has not exceeded 15 000 tonnes in recent years Calcite 1 Mineral Planning Factsheet Calcite Long Rake calcite Mine, Peak District A former source of vein calcite The purpose of this factsheet is to Mineral Planning Factsheet CalciteAbout Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone Limestone Crushing Process JXSC Mineral2021年10月1日 After many refinement efforts, work efficiency of the limestone crushing plant 09 unit increased 1731% to 80, 19%, to increase the production target, refinement efforts were made to increase (PDF) Evaluasi Kinerja Limestone Crushing Plant

Limestone: The Calcium Carbonate Chemical Sedimentary Rock

Limestone is a material of national importance, and resource sterilization can result in a longer haul at a higher cost from quarry to customer Limestone Production Patterns Most of the limestone that is mined is crushed for aggregate The majority of US crushed stone production has come from limestone for at least the last 40 years2017年1月27日 As an example, the specific energy demand for crushing of stone is around 130 kWh/ton (Ballantyne et al 2012, Ciężkowski et al 2017 whereas for thermomechanical pulp (TMP) production in (PDF) Analysis of Energy Consumption of Crushing Processes 2022年3月9日 This setup is a 500tph complete limestone crushing plant, the max input size is 1020mm, output sizes are 05mm, 519mm, 1925mm,2550mm It is configured with hopper, vibrating feeder DN6015, primary jaw crusher PE1200*1500, 2 sets impact crusher PF1520,4 sets vibrating screen 2YD3072, and 12 pcs belt conveyors Flowchart Explanation 1 The 500TPH Limestone Crushing Plant JXSC MachineDolomite crushing is in the beginning part of the whole mining process, so dolomite crushing process is quite important Like other minerals crushing process, we pull the raw dolomite explored from the mine into vibrating feeder, which feeding them continuously and evenly into dolomite crushing plant and in which dolomite raw materials get processed into the right Dolomite Ore Crushing Solutions DSMAC

.jpg)

2 Major Roles of Limestone in Cement Manufacturing

2023年5月27日 Cement manufacturing starts from the mining of raw materials, mainly, limestone and clay Generally, the mining method of limestone is open pit mining There are some underground limestone mines, but most of them are pits on the surface Step 2: Limestone crushing Most of the limestone rocks mined from the mine by blasting have large particle The study offers a detailed cost analysis of Calcite Production via Mining, Crushing, Washing, and Dry Processing In addition, the report incorporates the manufacturing process with detailed process and material flow, operating costs along with Calcite Production Cost Analysis Reports 2024 Procurement 2023年2月13日 The production capacity and efficiency of the limestone crushing equipment will depend on several factors, including the type of equipment, the material properties, and the capacity You should carefully consider the production capacity and efficiency of the equipment they are considering to ensure it meets their needsWhat Is The Best Limestone Crusher Limestone Crushing AGICO2023年2月14日 In conclusion, the limestone crushing process is a crucial step in the production of cement and other industries that utilize limestone as a raw material The quality of the final product depends on several factors, including Optimized Limestone Crushing Process for Increased

Lime and Limestone: Chemistry and Technology, Production and

2007年12月21日 When the choice of the raw material falls on marly limestone composed of 6520 wt% clays, the production process is obviously characterized by different temperatures and times and the finished 1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the Limestone Aggregate Crushing JXSC MachineThe calcite crusher can produce the raw materials in different Mosh hard with continuous performance The common calcite crushers are jaw crusher, cone crusher, impact crusher etc In the calcite crushing plant, the runofmine calcite is fed into jaw crusher for primary crushing, and then the crushed calcite is transferred to secondary crusher Calcite Ore Crushing Solutions DSMAC2024年5月23日 During cement production, calcite acts as a fluxing agent, lowering the melting temperature of raw materials, thereby conserving energy and enhancing production efficiency These functions of calcite collectively ensure the performance and quality of cement products, meeting the construction industry's demand for highperformance cementCalcite: A Key Ingredient in Efficient Cement Manufacturing

.jpg)

Industrial Production of Limestone Calcined Clay Cement (LC 3

2018年7月3日 Request PDF Industrial Production of Limestone Calcined Clay Cement (LC 3 ) – Experience and Insights The reduction of the clinker factor in cement has emerged as the most promising solution 2024年1月23日 Cement Production: Crucial raw material in cement preparation, obtained through the calcination process to produce quicklime Chemical Industry: Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feederLimestone crushing and screening production line introduction2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage2022年8月29日 Production line advantage 1 High degree of automation The entire production line requires almost no manual operations except for equipment startup, suspension and routine maintenance The production line has simple process, high production efficiency, large output and low operating costDolomite crushing and sand making production line