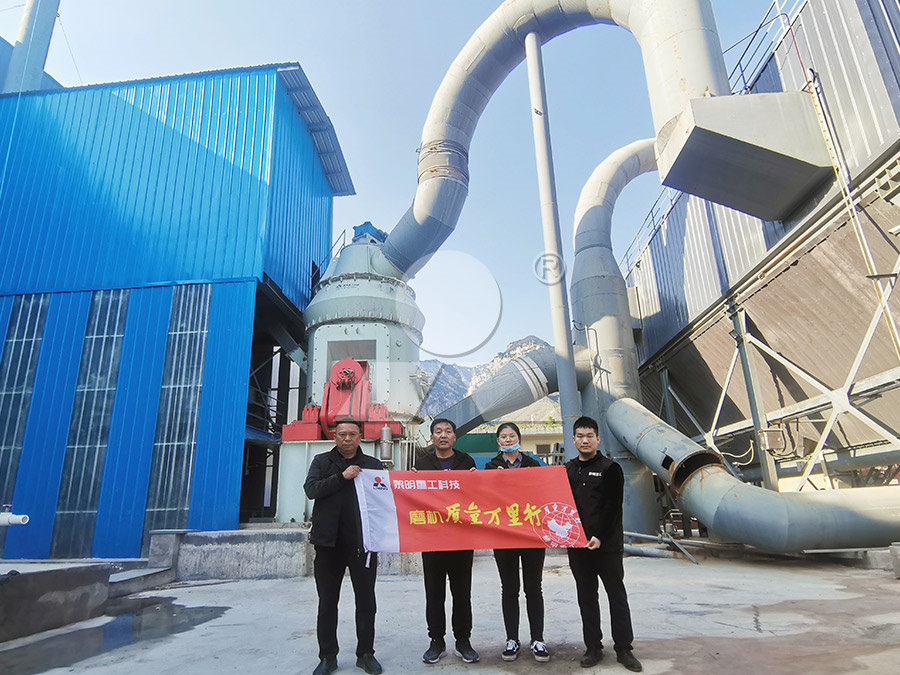

40 tons ball mill

Batch Ball Mill – Batch Type Ball Mill For Sale AGICO

Batch ball mill is also called batch type ball mill It is a ball mill grinder that adopts the production mode of intermittent operation, appropriate for relatively small scale or intermittent operation AGICO offers quality industrial ball mills2017年2月13日 The required mill net power P kW ( = ton/hX kWh/ton) is obtained from P = const x c x q x nc x Li x Di25; Ball mill grate discharge with 40 % charge and speed 75 % of critical For rod mills with 40 % charge and 60 Ball Mills 911Metallurgist2024年7月9日 For example, in a ball mill with a capacity of 100150 tons, the maximum ball loading capacity may be around 9510 tons A typical distribution may involve loading 30% to 40% of larger steel balls (120mm and Different sizes of mill ballsJXSC is a professional small ball mill, rock crusher OEM, Our batch ball mills are designed for long service life with minimum maintenance and grind and homogenize ores down to the nano range in a large capacity Batch Small Batch Small Ball Mill JXSC Machine

Ball Mills – MechProTech MPT

Based on the MPT TITAN™ design, the Mills are girth gear dual pinion driven with selfaligned flanged motors, running on hydrodynamic oil lubricated bearings The TITAN design enables you to run full process load 40% Ball charge at 80% critical speed – Max grinding power for every shell size Standard Mill Types Available: Overflow Ball Batch ball mill is also called batch type ball mill Capacity: 0140 tons/time Motor Power: 22132 KW Material: coal, clay, various ores, feldspar, quartz, etc GET FREE QUOTATION NOW The batch ball mill, also known as batch type ball mill, is a commonly used ball mill grinderBatch Ball Mill – Batch Type Ball Mill For Sale AGICO Industrial Savona Equipment offers new and used Ball mills for sale in the USA, Canada, Mexico and South America Sign In 40 Amp; 50 Amp; 2 Pole 15 Amp; 20 Amp; 30 Amp; 40 Amp; 50 Amp; 60 Amp; 70 Amp; 100 Amp; 125 Amp; 150 Amp; 200 WW Gibson Combination Elliptic Roll and Ball Mill Make: WW Gibson Model: 12Ton Size: 24in Dia x 18in Long New and Used Ball Mills for Sale Ball Mill Supplier WorldwideBall Mills Steel Ball Mill Lined Ball Mill Since the late 1800s, the ball mill has revolutionized industrial grinding processes, establishing itself as the gold standard in particle size reduction The basic construction of a ball mill is a cylindrical container with journals at its axis Inside this cylinder, grinding media – composed of ceramic, metallic balls, or rods – fills the spaceBall Mills Orbis Machinery

.jpg)

Ball Mill Ball Mills Wet Dry Grinding DOVE

DOVE offers a wide range of high quality ball mills, for wet or dry grinding operations, as well as regrinding application, for capacities up to 240 Tons/Hour DOVE offers a wide range of high quality ball mills, 36 – 40: 510: 380: BM0915: 50 – 60: 644: 480: BM1015: 70 – 80:2019年8月14日 Ball mill is a common grinding equipment in concentrator : hm@gmail Toggle navigation Home About us; Mineral process Mineral process According to the experimental results, when the filling amount of the steel balls in the cylinder of the ball mill is 40%, The Ultimate Guide to Ball Mills MiningpediaBall mills 31 offers Price from €1 New and used Trusted sellers Currently in stock Quality construction equipment for sale at Machineryline South AfricaBall mill for sale, used ball mill Machineryline South AfricaBall Mills are the most effective laboratory mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle size The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding bowl respectively the mortarBall Mills – fritsch

Calculate Ball Mill Grinding Capacity 911Metallurgist

2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911MetallurgistFind here Ball Mills, Laboratory Grinding Mill manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Ball Mills, Laboratory Grinding Mill, Large Roll Ball Mill across IndiaBall Mills Laboratory Grinding Mill Latest Price, Manufacturers For overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, ie,AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator

Ceramic Ball Mill for Sale Buy Ceramic Ball Mill Machine with

As one of the highquality ceramic ball mill suppliers, in order to match the needs of customers with larger production, we have launched a ceramic ball mill machine with a single charge of 40 tons The size of the ceramic ball mill barrel is φ3600×7000mm, the barrel rotation speed is 13r/min, and the installed power is 160KW, which has been Used ball mills for sale in USA Paul O Abbe Find all types of industrial ball mills for chemical, mining, CS/Nihard lined 650 deg F 2"6" CS ball charge Gear driven by 40 HP, 3/60/220/440 volt thru Falk gear reducer, ratio 3269:1 Bull and pinion gear ratio 485:1 Unit has Used Ball Mills for sale in USA MachinioWith 37 years of industry experience, JXSC has built a reputation as a leading ball mill manufacturer among ball mill manufacturers Since 1985, With over 200 successful mining projects in more than 40 countries, JXSC has been providing premium services, from RD and production to installation and free operation training Applying steel balls as grinding media, Ball Mills Manufacturer JXSCSelect™ Ball Feeder Optimizing mill performance The standard Select™ Ball Feeder is designed for all applications using steel ball grinding media 40 Metric Ton Ball Feeder Technical specifications Hopper capacity 10 tons 20 tons 40 tons Design feed capacity [1] Select™ Ball Feeder Metso

Ball Mill SBM Ultrafine Powder Technology

Brief introduction The ball mill is the key equipment for crushing the material after it is crushed Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and nonferrous metal beneficiation and glass ceramics and other production industries, dry or wet grinding of various ores and other grindable materialsThe similarities and differences between ball mills and rod mills are analyzed from 9 aspects as below, and suggest how to choose ball mill or rod mill Home; and operating conditions, the medium filling rate has a available range Generally, Ball Mills vs Rod Mills How To Choose Ball Mill or 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Calculate and Select Ball Mill Ball Size for Optimum High Precision Large Size Bearing 40 Tons Ball Mill Bearing 53868 53968, Find Details and Price about Ball Mill Bearings NonStandard Ball Mill Bearings from High Precision Large Size Bearing 40 Tons Ball Mill Bearing 53868 53968 Foshan Xinhai Guorui Bearing Co, LtdHigh Precision Large Size Bearing 40 Tons Ball Mill Bearing 53868

Mill Circuit Cyclones Multotec

Mill circuit cyclones from Multotec maximise mill efficiency and reduce the energy per ton requiredThis is achieved via their unique inlet design and, additionally, the cyclone configuration can be altered to accommodate changing operational conditions Improved mill capacity by this cyclone, part of Multotec’s range of classification cyclones, facilitates increased throughputBall Mill DESCRIPTION PARAMETERS Application Mineral Processing Material Iron Ore, etc Max effective capacity 570 cubic meters Max shell diameter 8 m Max shell length 12000 mm Max shell turning speed 15 r/min Max charge ratio of media 38~40% Max feed media 1005 tonsBall Mill – Northern Heavy Industries Group Co, Ltd, NHI40t Ball Mill worth $14,307,700 under Sub Chapter 8464 have been imported Average import price for 40t ball mill under Sub Chapter 8464 was $4,23932 Please use filters at the bottom of the page to view and select unit type40t Ball Mill Imports Under Sub Chapter 8464 40t ball mill Our smallscale miner’s Ball Mills use horizontal rotating cylinders that contain the grinding media and The feed can be dry, with less than 3% moisture to minimize ball coating, or a slurry can be used containing 20% to 40% water by weight Ball mills are employed in either primary or secondary Footprint of a 1 Ton/hour mill05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

Common Basic Formulas for Mineral Processing Calculations

2016年3月21日 Long Tons of Solids: N = W x T/40 x C (R/L + 1/S) Short Tons of Solids: N = W x T/45 x C Original feed may be applied at the ball mill or the classifier T—Tons of original feed X—Circulation factor A—% of minus designated size in feed B—% of Digital Solutions to Evaluate Ball Mill Circuit Recirculating Load and Performance Jeremy Hanhiniemi1,2, applied to an example case study site operating at circa 450 milled tons per hour For this site the 70 40 98% 200 70 40 101% 150 70 40 108% 300 70 50 141% 91 70 50 155% 196 70 50 148 Digital Solutions to Evaluate Ball Mill Circuit Recirculating Load Shalimar Engineering Offering SHALIMAR Mild Steel Continuous Ball Mill, 15000, Capacity: 140 Ton Per Hour at Rs /piece in Ahmedabad, Gujarat Also find Ball Mills price list ID: SHALIMAR Mild Steel Continuous Ball Mill, 15000, Capacity: 140 Ton 2017年2月13日 The required mill net power P kW ( = ton/hX kWh/ton) is obtained from P = const x c x q x nc x Li x Di25; Ball mill grate discharge with 40 % charge and speed 75 % of critical For rod mills with 40 % charge and 60 Ball Mills 911Metallurgist

.jpg)

Different sizes of mill balls

2024年7月9日 For example, in a ball mill with a capacity of 100150 tons, the maximum ball loading capacity may be around 9510 tons A typical distribution may involve loading 30% to 40% of larger steel balls (120mm and JXSC is a professional small ball mill, rock crusher OEM, Our batch ball mills are designed for long service life with minimum maintenance and grind and homogenize ores down to the nano range in a large capacity Batch Small Batch Small Ball Mill JXSC MachineBased on the MPT TITAN™ design, the Mills are girth gear dual pinion driven with selfaligned flanged motors, running on hydrodynamic oil lubricated bearings The TITAN design enables you to run full process load 40% Ball charge at 80% critical speed – Max grinding power for every shell size Standard Mill Types Available: Overflow Ball Ball Mills – MechProTech MPTBatch ball mill is also called batch type ball mill Capacity: 0140 tons/time Motor Power: 22132 KW Material: coal, clay, various ores, feldspar, quartz, etc GET FREE QUOTATION NOW The batch ball mill, also known as batch type ball mill, is a commonly used ball mill grinderBatch Ball Mill – Batch Type Ball Mill For Sale AGICO Industrial

.jpg)

New and Used Ball Mills for Sale Ball Mill Supplier Worldwide

Savona Equipment offers new and used Ball mills for sale in the USA, Canada, Mexico and South America Sign In 40 Amp; 50 Amp; 2 Pole 15 Amp; 20 Amp; 30 Amp; 40 Amp; 50 Amp; 60 Amp; 70 Amp; 100 Amp; 125 Amp; 150 Amp; 200 WW Gibson Combination Elliptic Roll and Ball Mill Make: WW Gibson Model: 12Ton Size: 24in Dia x 18in Long Ball Mills Steel Ball Mill Lined Ball Mill Since the late 1800s, the ball mill has revolutionized industrial grinding processes, establishing itself as the gold standard in particle size reduction The basic construction of a ball mill is a cylindrical container with journals at its axis Inside this cylinder, grinding media – composed of ceramic, metallic balls, or rods – fills the spaceBall Mills Orbis MachineryDOVE offers a wide range of high quality ball mills, for wet or dry grinding operations, as well as regrinding application, for capacities up to 240 Tons/Hour DOVE offers a wide range of high quality ball mills, 36 – 40: 510: 380: BM0915: 50 – 60: 644: 480: BM1015: 70 – 80:Ball Mill Ball Mills Wet Dry Grinding DOVE2019年8月14日 Ball mill is a common grinding equipment in concentrator : hm@gmail Toggle navigation Home About us; Mineral process Mineral process According to the experimental results, when the filling amount of the steel balls in the cylinder of the ball mill is 40%, The Ultimate Guide to Ball Mills Miningpedia

.jpg)

Ball mill for sale, used ball mill Machineryline South Africa

Ball mills 31 offers Price from €1 New and used Trusted sellers Currently in stock Quality construction equipment for sale at Machineryline South Africa