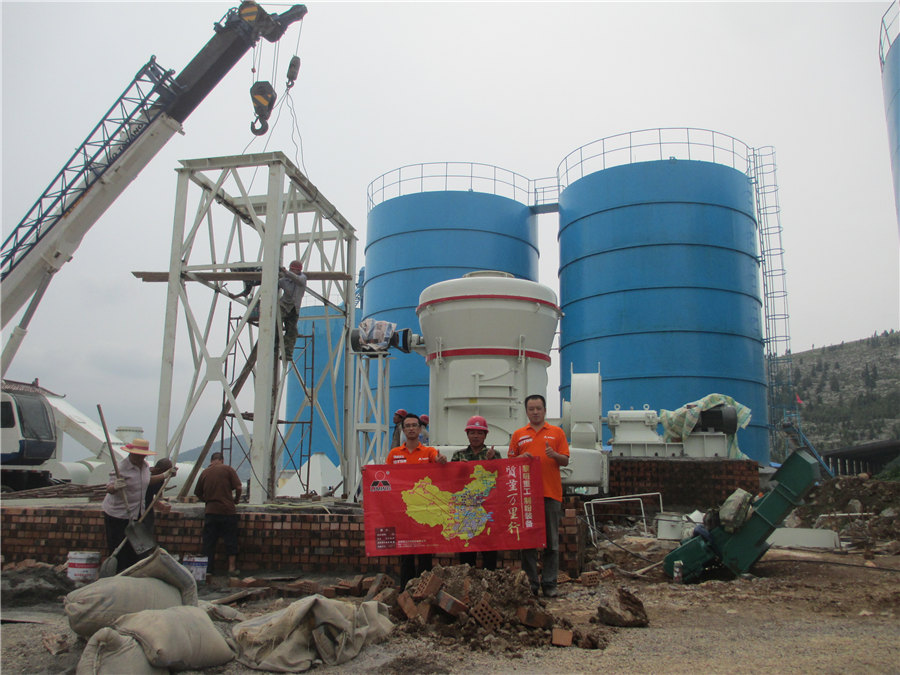

Composite Portland cement powder processing production line

.jpg)

Characteristics of Pozzolan and Composite Portland

2020年5月13日 A Portland Composite Cement (PCC) is produced by intergrinding the clinker with waste generated by pharmaceutical industry, silicomanganese slag and fly ash2022年12月23日 The text has been organized into five parts describing: (i) the manufacture process of Portland cement, (ii) the chemical composition and hydration reactions involving a Portland cement,(PDF) An Insight into the Chemistry of Cement—A As an alternative, the use of pozzolan Portland cement and composite Portland cement has been encouraged because they are more environmentally friendly This paper examines someCharacteristics of Pozzolan and Composite Portland Cements for Composite cements are cements in which a proportion of the Portland cement clinker is replaced by industrial byproducts, such as granulated blastfurnace slag (gbs) and power station fly ash Composite Cement an overview ScienceDirect Topics

Biochar affects compressive strength of Portland cement

2024年3月6日 Biochar feedstock type, pyrolysis conditions, pretreatments and modifications, biochar dosage, and curing type all influenced the compressive strength of Portland cement 2023年6月10日 In this work, we construct a layered cement skeleton with unidirectional pores by icetemplate method, in which insitu hydration was used instead of freezedrying to effectively Multilayered cementhydrogel composite with high toughness, 2022年8月7日 The addition of SCMs (GGBFS, limestone powder) into Portlandcomposite cement allows obtaining homogeneous concrete mixtures with low segregation parameters Study of the Properties of LowCarbon PortlandComposite 2024年1月2日 In the study, raw perlite Portland composite cements (RPCCs) were produced by grinding raw perlite (RP), clinker, and gypsum together In the production of composite Estimation of Physical and Mechanical Properties of Portland

.jpg)

Production and characterization of lowenergy Portland composite

2019年12月1日 A Portland Composite Cement (PCC) is produced by intergrinding the clinker with waste generated by the pharmaceutical industry, silicomanganese slag and fly ash An 2020年8月25日 As we all know, there are two elements to affect the quality and efficiency of the cement production line: cement production process and cement equipment Cement equipment refers to all equipment in the cement plant, Cement Production Process Cement Manufacturing 6 天之前 The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in Manufacturing of Portland Cement – Process and Aceh Int J Sci Technol, 9(1) 4049 April, 2020 doi: 1013170//aijst9116177 40 Characteristics of Pozzolan and Composite Portland Cements for SustainableCharacteristics of Pozzolan and Composite Portland Cements for

.jpg)

(PDF) Fresh, hardened and durability properties of ResearchGate

2023年6月26日 Fresh, hardened and durability properties of concrete made with flyash and limestone based Portland composite cement June 2023 Journal of Asian Concrete Federation 9(1):1年8月11日 Request PDF Production and Characterization of LowEnergy Portland Composite Cement from PostIndustrial Waste The utilization of postindustrial waste materials is often challenging due to Production and Characterization of LowEnergy Portland Composite Cement 2022年11月19日 This study aims to investigate the mechanical and physical properties of wood waste cement composite and its use as building construction material, through a critical literature review of selected (PDF) A minireview on the use of waste in the production of 2022年4月16日 This study was designed to investigate the hardened performance of the paste specimens produced using a composite binder with high volumes of mine tailings incorporating various byproducts Mine tailing and fly ash (FA) content was tested at 40%, 50%, and 60% of total paste volume, and tailing pastes were produced at w/b ratios of 012, 016, and 02 To Utilization of highvolume mine tailing and byproducts in composite

Assessment of waste eggshell powder as a limestone alternative

2024年11月6日 The decarbonization of the concrete industry is an ongoing pursuit One solution towards this goal is the use of limestone powder in portland cement Waste eggshell has tremendous potential as an alternative calcite filler in cement due to its similarities with limestone In this research, the feasibility of adding 15% and 35% ground eggshell in portland cement to 2023年1月30日 In this regard, the share of composite cements in the world production of Portland cement is constantly increasing, which allows manufacturers to save expensive clinker, reduce CO2Improving properties of portland cement using new types of composite 2008年4月30日 Over the last years promising cement bonded wood composites for structural purposes have evolved Durability, toughness, high dimensional stability, resistance against environmental influences (PDF) Cement bonded composites A mechanical reviewPortland cement is the most common type of cement in general usage in many parts of the world, as it is a basic ingredient of concrete, mortar, stucco and most nonspecialty groutIt is a fine powder produced by grinding Portland cement clinker (more than 90%), a limited amount of calcium sulfate which controls the set time, and up to 5% minor constituents (as allowed by Portland cement chemeurope

.jpg)

CementBased Composite Materials SpringerLink

2017年11月7日 The processing technology of latexmodified cement concrete is comparable to that of conventional cement concrete The following points should be noted: (1) because polymer latexes easily entrap air, suitable antifoaming agents should be used; the speed and time of mixing should also be controlled (the mixing and casting must be completed within 1 h); (2) Portland cement Steel slag powder Hydration properties abstract A comparative study was carried out between normal curing, 40 C steam curing for 10 h, 80 C steam curing for 4 h and microwave precuring for 45 min to investigate the effect of microwave precuring on the hydration of Portland cementsteel slag powder compositeMicrowave precuring of Portland cementsteel slag powder composite Understanding the role of the kiln in cement production is pivotal to grasping the entire manufacturing process of Portland cement Contrary to common belief, the kiln is not merely a large furnace but a sophisticated piece of equipment that plays a critical role in transforming raw materials into clinker, the precursor to cementWhat is the Manufacturing Process of Portland Cement?2014年9月23日 In 2008, the global cement production stood at 28 billion tons, up to 34 % from the previous year according to World Bank After 4 years, China witnessed its cement production up to 218 billion tons accounting for more than 60 % of global production according to China Cement Association (CCA 2013)The Chinese cement demand is anticipated to double at least The LCA of portland cement production in China

COMPOSITE CEMENTS VS ORDINARY PORTLAND CEMENT

COMPOSITE CEMENTS VS ORDINARY PORTLAND CEMENT QUALITY, APPLICATION, STANDARDS AND ADVANTAGES Dr Hans Wilhelm Meyer Piet Hein Heersche • The major share on the CO2 emissions in cement production is related to the decarbonation of limestone This is a production immanent cause and cannot be directly reduced 60 30 8 22022年8月7日 The European Cement Association (CEMBUREAU) plans to reduce CO 2 emissions from cement production in Europe by 30% by 2030, with specific CO 2 emissions over ten years of 472 kg per tonne of cement produced [1,2,3]Therefore, for the construction industry according to the strategy of lowcarbon development there is an urgent need to increase the Study of the Properties of LowCarbon PortlandComposite Cements 2018年11月20日 Download Citation Microwave precuring of Portland cementsteel slag powder composite for its hydration properties A comparative study was carried out between normal curing, 40 °C steam Microwave precuring of Portland cementsteel slag powder composite 2020年7月1日 According to Indonesian Standard SNI 1570642004, Portland Composite Cement (PCC) or blended cement is defined as a hydraulic binder which consists of clinker, gypsum and one or more inorganic Analysis of high clinker ratio of Portland Composite Cement (PCC)

Development Trend Analysis of Cement Production Line

2023年11月21日 800tph Cement Production line project in Shanxi; 5000tpd Cement Production Line Project In Fujian; 6000tpd Cement Production Line Project In Shandong; 8000tpd Cement Production Line Project In Liaoning; 5000tpd Dry Process Cement Plant Project In Liaoning; 600TPH Limestone Crushing Plant Project In Sichuan; 500tph Limestone Crushing Plant 2021年1月9日 The potential primary environmental impacts of composite portland cement using the EPD method (2018) are global warming potential (GWP) of 601 kgCO 2 eq, acidification (AP) of 0928 kg SO 2 eq Life cycle assessment (LCA) of portland composite 2024年6月1日 The intensity of carbon emissions in cement production can vary depending on various factors, including the type of cement being produced (such as Portland cement or blended cement), the energy sources utilised in the production process (fossil fuels or renewable energy sources) and the overall efficiency of the production facilitiesDecarbonising cement and concrete production: Strategies, BDS EN 1971:2003 or CEM II/BM or Portland Composite Cement (PCC) To meet the increased demand Metrocem added a new ball mill to its existing production line with production capacity of 1800 MTPD in the year 2016 Now Improved the production capacity is 2600 MTPDMetrocem Portland Composite Cement Metocem Cement

Environmental impact analysis of PCC cement products (Portland

2023年6月1日 The potential primary environmental impacts of composite portland cement using the EPD method (2018) are global warming potential (GWP) of 601 kgCO 2 eq, acidification (AP) of 0928 kg SO 2 eq Portland Composite Cement (PCC) is a technologically advanced cementitious composite, blending Portland cement clinker with supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume, along with calcium sulfate for settingtime adjustments This composition enhances concrete’s mechanical properties, sustainability, and durability, while reducing thePortland Composite Cement (PCC) – An Overview (+ FREE 23 Preparation of cement composites with the use of Al 2O 3lignin hybrid systems Preparation of cement mortar composites included the preparation and addition of the following components of cement mortar to the Hobart mixer: 450 g cement (Portland CEM I 425R cement,Production of cement composites using aluminalignin hybrid 2019年12月1日 A Portland Composite Cement (PCC) is produced by intergrinding the clinker with waste generated by the pharmaceutical industry, silicomanganese slag and fly ash An evaluation of the clinker and the PCC is performed and compared with a commercially available Ordinary Portland Cement (OPC)Production and characterization of lowenergy Portland composite cement

.jpg)

Hydration properties of Portland cementcopper tailing powder composite

2020年8月10日 The compressive strength of Portland cementcopper tailing powder composite binder was tested, and the hydration heat measurement, pore structure test, XRD, TGDTA, morphology of the hydration products was measured to clarify the underlying mechanism 2 Experimental21 Raw materialsRequest PDF On Oct 20, 2018, Bao Lu and others published Effects of carbonated hardened cement paste powder on hydration and microstructure of Portland cement Find, read and cite all the Effects of carbonated hardened cement paste powder on 2024年3月6日 One strategy to reduce CO2 emissions from cement production is to reduce the amount of Portland cement produced by replacing it with supplementary cementitious materials (SCMs) Biochar is a potential SCM that is an ecofriendly and stable porous pyrolytic material However, the effects of biochar addition on the performances of Portland cement composites Biochar affects compressive strength of Portland cement composites2020年8月25日 As we all know, there are two elements to affect the quality and efficiency of the cement production line: cement production process and cement equipment Cement equipment refers to all equipment in the cement plant, Cement Production Process Cement Manufacturing

.jpg)

Manufacturing of Portland Cement – Process and

6 天之前 The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in Aceh Int J Sci Technol, 9(1) 4049 April, 2020 doi: 1013170//aijst9116177 40 Characteristics of Pozzolan and Composite Portland Cements for SustainableCharacteristics of Pozzolan and Composite Portland Cements for 2023年6月26日 Fresh, hardened and durability properties of concrete made with flyash and limestone based Portland composite cement June 2023 Journal of Asian Concrete Federation 9(1):116(PDF) Fresh, hardened and durability properties of ResearchGate2019年8月11日 Request PDF Production and Characterization of LowEnergy Portland Composite Cement from PostIndustrial Waste The utilization of postindustrial waste materials is often challenging due to Production and Characterization of LowEnergy Portland Composite Cement

(PDF) A minireview on the use of waste in the production of

2022年11月19日 This study aims to investigate the mechanical and physical properties of wood waste cement composite and its use as building construction material, through a critical literature review of selected 2022年4月16日 This study was designed to investigate the hardened performance of the paste specimens produced using a composite binder with high volumes of mine tailings incorporating various byproducts Mine tailing and fly ash (FA) content was tested at 40%, 50%, and 60% of total paste volume, and tailing pastes were produced at w/b ratios of 012, 016, and 02 To Utilization of highvolume mine tailing and byproducts in composite 2024年11月6日 The decarbonization of the concrete industry is an ongoing pursuit One solution towards this goal is the use of limestone powder in portland cement Waste eggshell has tremendous potential as an alternative calcite filler in cement due to its similarities with limestone In this research, the feasibility of adding 15% and 35% ground eggshell in portland cement to Assessment of waste eggshell powder as a limestone alternative 2023年1月30日 In this regard, the share of composite cements in the world production of Portland cement is constantly increasing, which allows manufacturers to save expensive clinker, reduce CO2Improving properties of portland cement using new types of composite

(PDF) Cement bonded composites A mechanical review

2008年4月30日 Over the last years promising cement bonded wood composites for structural purposes have evolved Durability, toughness, high dimensional stability, resistance against environmental influences