Vertical shaft bottom design

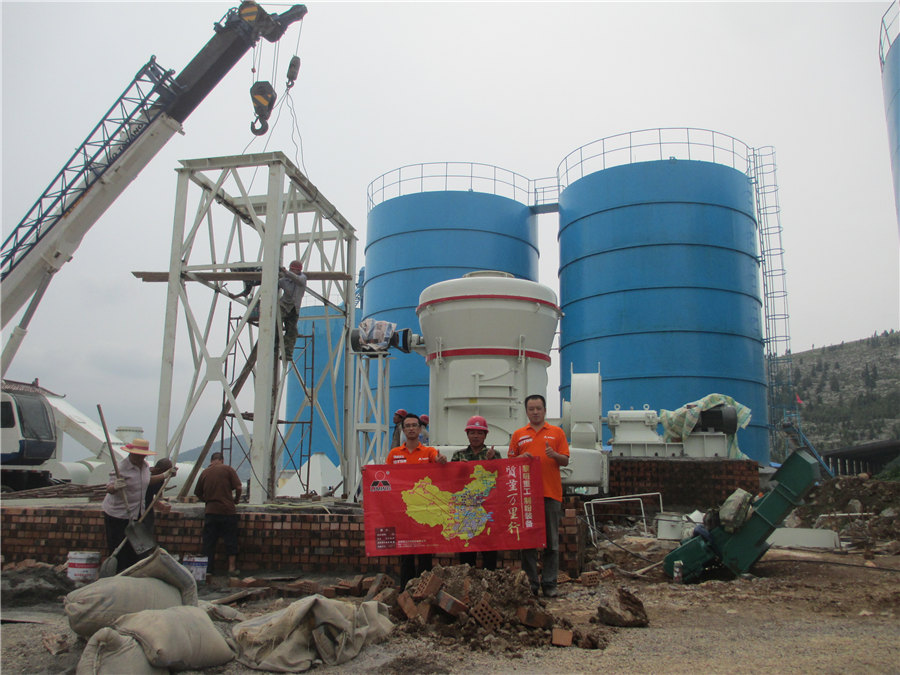

CFB石灰石脱硫剂制备96.jpg)

A review ofsome aspects ofshaft design SAIMM

orebody Inclined shaft Vertical shaft over incline degrees metres metres I % 15 6066 I 7742 +27,6 20 4450 5791 I +30,1 25 3672 I 4450 +22,7 35 2499 I 3048 I +22,0 45 1707 2225 I +30,3 55 2012年1月1日 Vertical shafts have a higher ground coverage compared to surface parallel inclined shafts The increased rock mass cover and therefore higher insitu stress magnitudes (eg decreasing riskDesign aspects of concrete lined vertical shafts for 2024年4月2日 The surrounding rock pressure of vertical shafts is one of the basic parameters of shaft lining design Investigating its calculation methods and applicable scopes has great Calculation method and evaluation of surrounding rock pressure Vertical shafts have a higher ground coverage compared to surface parallel inclined shafts The increased rock mass cover and therefore higher insitu stress magnitudes (eg decreasing risk for hydrofracturing) may allow unlined Design aspects for concrete lined vertical shafts for

ITA Working Group n° 23 Shaft Design and Construction

In mining when the top of the excavation is the ground surface, it is referred to as a «shaft»; when connecting diferent levels in a mine and the top of the excavation is underground, it is called a The convergence–confinement method (usually applied to tunnels), with consideration of gravitational effects and the threedimensional conditions near a shaft, is proposed as a tool to Design and performance evaluation of vertical shafts: rational shaft 2019年9月1日 The authors have developed a new, smalldiameter vertical shaft construction system over the course of a decade, in order to improve the dangerous and unfavorable Smalldiameter vertical shafts constructed in the shallow space of 2023年5月18日 Vertical shaft development (Fig 1) is the most widely used development method in underground mines and is suitable for the development of steeply inclined and deeply Vertical Shaft Development SpringerLink

An Inspection and Surveying System For Vertical Shafts ARAA

This paper introduces the overall design concept of the Vertical Opening Inspection System, and gives a brief overview of the first prototype (VOIS mk I), which2024年8月3日 Using the Vertical Shaft Sinking Machine (VSM) The ring bottom beam design effectively reduces convergence deformation by about 50%, (PDF) A Numerical Study of Reinforcement Structure in Shaft 2022年3月7日 There are indications that buildings that include vertical shafts can affect the performance of buildings Many Publications in major peerreviewed journals from different fields THERMAL PERFORMANCE OF VERTICAL SHAFTS IN 2023年5月18日 Hanging Shaft Development When the foot wall and flank of the deposit do not meet the construction conditions, or their engineering geological conditions are not suitable for arranging the shaft, or the dip angle of the deposit is approximately vertical or horizontal, or hanging wall shaft arrangement can reduce the distance from the processing plant or Vertical Shaft Development SpringerLink

Tunnel Shafts: Types, Construction, and Advantages

Tunnel shafts are vertical passages that connect the ground surface to the tunnel roof Shafts have many advantages and are used in constructing tunnels When the position and course of the tunnel are correctly aligned and accordingly set out on the surface, shafts are sunk at defined points on the tunnel line to aid tunneling operationsGround deformations around axisymmetric shafts cannot be determined with the design approaches currently available, which are mostly based on plasticity methods The convergence–confinement method (usually applied to tunnels), with consideration of gravitational effects and the threedimensional conditions near a shaft, is proposed as a tool to predict Design and performance evaluation of vertical shafts: rational shaft countries The design of the shaft size is the most important part of VSBK because it determines the dimensions of the entire VSBK structure The shaft design also plays an important role in the performance of VSBK Any fault in the design of shaft can lead to failure of the kiln Also, once designed and constructed, the shaft size cannotVERTICAL SHAFT BRICK KILNKeywords: vertical shaft completion, decrease of transient periods by means of application of efficient equipment and multifunctional steel angle headgears 1 Introduction Currently the tendency to reject the construction of vertical shafts is dominated in the design of new Kuzbass mines ± the preference is given to the slop miningEngineering and process design solutions for the vertical shaft

.jpg)

Vertical Turbine Pumps Intro to Pumps

Mixedflow vertical turbines are large vertical turbines used in municipal water supply, largescale industrial applications, desalination applications, as well as flood control Depending on the impeller design, mixedflow impellers may be enclosed (such as those shown in the diagram) or open (similar to those shown in the axialflow diagram below)This report describes the development of skip and guide designs for vertical shafts in deep vein mines Skip and guide systems for bottom dump skips are identified as being used in current practice Mine visits were made to obtain current information on the needs and problems of operating minesDevelopment of Vertical Shaft Skip and Guide Design2011年10月1日 The article is devoted to analysis of deformation of an icesoil retaining structure during a vertical mine shaft sinking by applying the artificial ground freezing technique(PDF) Shaft Sinking and Lining Design for a Deep Potash Shaft in the shaft bottom 2000’s • Introduction of full shaft bottom sidewall cladding 5 A changing environment in which productivity will have to be improved The way in which a shaft is sunk is strongly influenced by both geotechnical and prevailing local social and political conditions, all within a legislativeAPPROACHES TO IMPROVE SAFETY AND RECOVER LOST

.jpg)

Vertical Shaft Sinking Machine (VSM) Herrenknecht

Since its development in 2004, Herrenknecht VSM (Vertical Shaft Sinking Machine) technology has established itself worldwide for the safe and efficient construction of vertical shafts This unique mechanical shaft sinking process demonstrates its strengths particularly under groundwater and can be used in almost all types of ground with a compressive strength of up 2019年9月1日 Figure 5 presents an image taken from the bottom of a vertical shaft of 30 m in diameter and 30 m in depth The workers are located here, at the bottom of the in the vertical shaft design, the shaft friction resistance between the vertical shaft and surrounding ground can also be considered to determine the shaft Smalldiameter vertical shafts constructed in the shallow space 2024年8月3日 Using the Vertical Shaft Sinking Machine (VSM) for shaft construction is an emerging modern technology, which is also currently one of the most advanced techniques in the field of shaft sinking Current research on VSM technology primarily focuses on mechanical and technical issues, neglecting the impact of the construction on the surrounding soil and the A Numerical Study of Reinforcement Structure in Shaft MDPIorebody Inclined shaft Vertical shaft over incline degrees metres metres I % 15 6066 I 7742 +27,6 20 4450 5791 I +30,1 25 3672 I 4450 +22,7 35 2499 I 3048 I +22,0 45 1707 2225 I +30,3 55 1402 1646 +17,4 65 1219 1158 5,0 75 1219 853 42,9 i I TABLE Il Comparison ofhorizontal tunnel lengths for inclined shaft versus conventional vertical shaft A review ofsome aspects ofshaft design SAIMM

A Highlevel Overview of Different Shaft Linings SRK

Selection of the most appropriate type of shaft lining needs to be considered during the design phase This document provides a highlevel overview of the typical Most commonly “bottom up” construction in the form of a raisebore/blind bore the rings are then bolted along the horizontal flanges to form the vertical shaft liningShaft Design •Material Selection (usually steel, unless you have good reasons) •Geometric Layout (fit power transmission equipment, gears, pulleys) A vertical wormgear speed reducer (Courtesy of the Cleveland Gear Company) Figure 7–2 (a) Choose a shaft configuration to support and locate the two gears and twoDesign of Shafts IIT Bombay2021年11月18日 When mounting bearings, one of the most common procedures is to use a vertical shaft mounting position and work with heat Considering all common mounting Skip to content Sunday, December 1, 2024 Mining Supply Tenders; As this is a monobloc design, the casing is turned sideways (fig 13) Fig 13: UNDERSTANDING VERTICAL SHAFT MOUNTING FOR BEARINGSorebody vertical shaft incline shaft Increase in length degrees metres metres % 15 1098 4085 272,0 20 1098 3110 183,2 25 I 1098 2531 130,5 35 1098 1890 72,1 45 1098 1555 41,6 55 1098 1341 22,2 65 1098 1220 11,1 75 1098 1159 5,6 SPECIFIC TYPES OF SHAFT:For the purpose of this paper there are only two types of shaft: (i) inclined shafts, and (ii A review of some aspects of shaft design Sabinet African

.jpg)

Basis for the Design ,of Smoke Shafts Springer

S MOKE shaft is defined in this paper as a vertical shaft of noncom bustible construction that extends from the bottom to the top of a building and has openings at the top to the outside and openings to floor spaces at each story These openings are sealed with dampers In the event2022年2月28日 Shafts vary in diameters and depths due to the varying lengths and diameters of the jacking pipes used to create the sewer network The design of shafts is very much aligned to the design of a typical deep excavation After mTBM retrievals, permanent prefabricated cylindrical manholes are built bottomup in these temporary shaftsDeep Shaft Excavation: Design, Construction, and Their ChallengesGround deformations around axisymmetric shafts cannot be determined with the design approaches currently available, which are mostly based on plasticity methods The convergence–confinement method (usually applied to tunnels), with consideration of gravitational effects and the threedimensional conditions near a shaft, is proposed as a tool to predict Design and performance evaluation of vertical shafts: rational shaft From head frame to shaft bottom, we work with you to design and deliver systems fit for the application, based on more than a century of experience implementing mine shaft systems and productivity, the mine shaft is the vertical pathway connecting a mine’s underground workings to surface processing plete mine shaft equipment from FLS

.jpg)

Bottom Support options SPX FLOW UTG Mixing Group

In order to strengthen the system, additional bottom supports are occasionally applied in the agitator design Bottom supports giving the shaft a second fulcrum are normally applied to structures with extra tall shafts or high bending moment Generally, bottom bearings are avoided as they always increase the number of maintainable partsVertical shafts that are dedicated to or mainly used for lifting mineral products are called main shafts; and those mainly used for lifting waste rock or gangue, or personnel are called service shafts The service shafts and most of the main shafts are also used for mine ventilationVertical Shaft, Types and Functions of SpringerLink2021年6月20日 In this research, the flow energy dissipation rate was measured in the vertical shaft of the vortex drop shaft experimentally Also, the impacts of the inflow Froude number and the inlet structure bottom slope on the flow energy dissipation rate in the vertical shaft were investigated The experiments are designed using the experimental design by full factorial Experimental Evaluation of Vertical Shaft Efficiency in Vortex Flow Bearing Selection, and Shaft and Housing Design (1) Type of Machine (2) Main spindle orientation (3) Diameter and size of main spindle NC Lathe, machining center, grinding machine, etc Vertical, horizontal, variabledirection, inclined, etc #30, #40, #50, etc (4) Shape and mountingrelated dimensions of main spindle2 Bearing Selection, and Shaft and Housing Design NTN

Special Designs: Vertical Pumps Springer

Verticalshaft installations of singlesuction pumps with a suction elbow are commonly furnished with Vertical singlesuction pumps with bottom suction are commonly used for larger sewage, water reason for use of the verticalshaft design is 2022年11月17日 A shaft may be either vertical or inclined (between 45 and 90 degrees to the horizontal), although most modern mine shafts are vertical If access exists at the bottom of the proposed shaft and ground conditions allow then raise boring may be used to excavate the shaft from the bottom up, such shafts are called borehole shaftsShaft Mining Encyclopedia MDPI2011年12月17日 Guide Bearing The bearing opposite the thrust bearing (usually the lower or “bottom” bearing) is called the guide bearing (Figure 5) Its function is to locate the lower end of the motor shaft and withstand momentary upthrust (ie, 30 percent of standard high thrust in the direction opposite the thrust bearing for no more than ten seconds)Operation and Maintenance of Vertical Motors Pumps2024年8月3日 Using the Vertical Shaft Sinking Machine (VSM) The ring bottom beam design effectively reduces convergence deformation by about 50%, (PDF) A Numerical Study of Reinforcement Structure in Shaft

THERMAL PERFORMANCE OF VERTICAL SHAFTS IN

2022年3月7日 There are indications that buildings that include vertical shafts can affect the performance of buildings Many Publications in major peerreviewed journals from different fields 2023年5月18日 Hanging Shaft Development When the foot wall and flank of the deposit do not meet the construction conditions, or their engineering geological conditions are not suitable for arranging the shaft, or the dip angle of the deposit is approximately vertical or horizontal, or hanging wall shaft arrangement can reduce the distance from the processing plant or Vertical Shaft Development SpringerLinkTunnel shafts are vertical passages that connect the ground surface to the tunnel roof Shafts have many advantages and are used in constructing tunnels When the position and course of the tunnel are correctly aligned and accordingly set out on the surface, shafts are sunk at defined points on the tunnel line to aid tunneling operationsTunnel Shafts: Types, Construction, and AdvantagesGround deformations around axisymmetric shafts cannot be determined with the design approaches currently available, which are mostly based on plasticity methods The convergence–confinement method (usually applied to tunnels), with consideration of gravitational effects and the threedimensional conditions near a shaft, is proposed as a tool to predict Design and performance evaluation of vertical shafts: rational shaft

VERTICAL SHAFT BRICK KILN

countries The design of the shaft size is the most important part of VSBK because it determines the dimensions of the entire VSBK structure The shaft design also plays an important role in the performance of VSBK Any fault in the design of shaft can lead to failure of the kiln Also, once designed and constructed, the shaft size cannotKeywords: vertical shaft completion, decrease of transient periods by means of application of efficient equipment and multifunctional steel angle headgears 1 Introduction Currently the tendency to reject the construction of vertical shafts is dominated in the design of new Kuzbass mines ± the preference is given to the slop miningEngineering and process design solutions for the vertical shaft Mixedflow vertical turbines are large vertical turbines used in municipal water supply, largescale industrial applications, desalination applications, as well as flood control Depending on the impeller design, mixedflow impellers may be enclosed (such as those shown in the diagram) or open (similar to those shown in the axialflow diagram below)Vertical Turbine Pumps Intro to PumpsThis report describes the development of skip and guide designs for vertical shafts in deep vein mines Skip and guide systems for bottom dump skips are identified as being used in current practice Mine visits were made to obtain current information on the needs and problems of operating minesDevelopment of Vertical Shaft Skip and Guide Design

(PDF) Shaft Sinking and Lining Design for a Deep Potash Shaft

2011年10月1日 The article is devoted to analysis of deformation of an icesoil retaining structure during a vertical mine shaft sinking by applying the artificial ground freezing technique