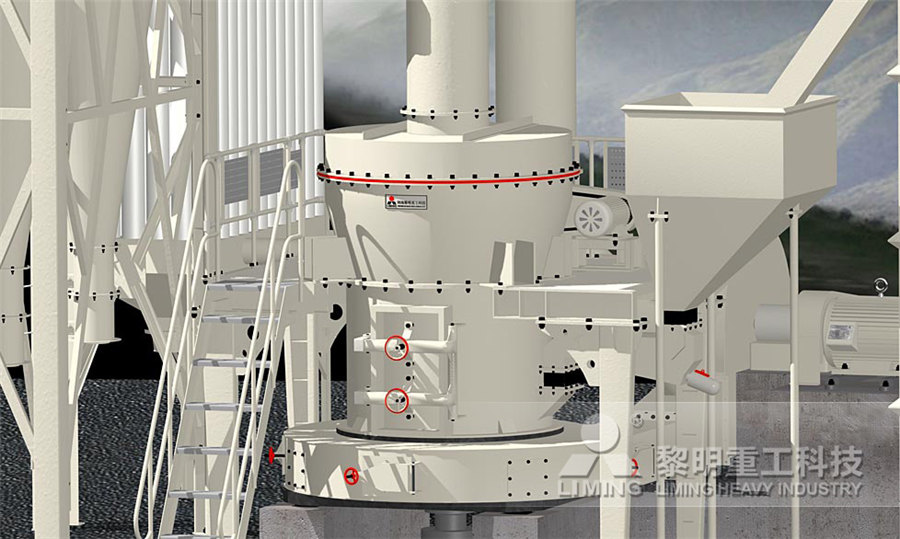

Quick lime limestone powder production line equipment

Active Lime Production LineHenan Zhengzhou Mining

We can provide technological solutions and complete production equipment for 50800TPD quicklime (active lime) production lineQuicklime A monoxide of calcium (CaO), is often referred to as burnt lime It is a white, caustic, alkaline, crystalline solid and manufactured from limestone, which is extracted from quarries and mines Limestone is usually crushed and fed QUICK LIME SHC Group Vietnam SHC Techmicom2022年4月20日 Lime is divided into quick lime and slaked lime After being calcined, limestone becomes calcium oxide CaO (commonly known as quicklime), which is generally in the form of lumps and is used in water quality treatment, Limestone crushing and grinding production line2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and Limestone crushing technology and equipment SBM

What is Lime: Lime vs Limestone Mintek Resources

2020年7月17日 It is vital in the production of countless materials Lime, or calcium oxide (CaO), is derived from high quality natural deposits of limestone, or calcium carbonate (CaCO3) Limestone is a sedimentary rock that formed millions of years ago as the result of the accumulation of shell, coral, algal, and other ocean debris2024年8月14日 Great! Let’s continue with Section 2, where we’ll dive into the Coating Equipment Production Line This section will explore the machinery and systems that play crucial roles in the powder coating process Section 2: Coating Equipment Production Line Section 2: Coating Equipment Production LineCoating Equipment Production Line Powder Coating EquipmentActive Lime Production Line Capacity : 502000t/d Applicable Materials : limestone, dolomite, chalk, etc Applications: steel smelting, chemical industry and power plant desulfurizatiol and other fields Case Description: The active lime production line is a kind of equipment and process used to produce active limeActive Lime Production Line Hongji Mining MachineryQuick Lime Powder Quick Lime Powder also known as Calcium oxide (CaO) or burnt lime, is a chemical compound that is widely usedIt is a caustic, white, alkaline, crystalline solid at room temperature The term "lime" refers to calciumcontaining inorganic materials that primarily consist of carbonates, oxides, and hydroxides of calcium, silicon, magnesium, aluminum, and ironQuick Lime Powder

Limestone Powder Suppliers in India: Quality Limestone Powder

We use stateoftheart equipment to process the limestone into a fine powder within the Khinwsar Tehsil, our advanced manufacturing plant boasts impressive capacities: 90 TPD for Quick lime powder and 150 TPD for Hydrated Lime Powder Limestone powder is used as a raw material in the production of ceramics, such as tiles, bricks, At Calmine India Pvt Ltd, we are committed to providing the highest quality limebased products to our customersWe are a leading manufacturer of Quick Lime Lumps, Hydrated Lime Powder, Quick Lime Powder, and Lime Stone, all of which are produced using stateoftheart technology and the finest natural materialsCalmine India Pvt LtdLimestone in the preheater will be preheated by the hot air, then it will be discharged to rotary kiln through chute that connecting preheater and kiln, it will stay in the kiln for 152 hours for calcination, during the process, it will be calcinated with temperature around 1300 ℃, after which comes limestone decomposition and release of co2,then the for mation of quick lime qill be Active Lime Production LineIndustrial Grade Hydrated Lime Production Line Equipment for Water Treatment Get Best Price Energy Saving Quick Lime Production Line with High Lime Activeness Get Best Price Contact Us 86 while limestone 600TPD Vertical Shaft Kiln Lime Production Line

.jpg)

Limestone Fertilizer Production Line

The limestone fertilizer production line is to make lim Fertilizer Machine Production Line Phone Whatsapp: +86 The limestone powder can be mixed with other components such as ammonium nitrate, Our fertilizer production equipment has been successfully delivered to Australia without any damageThe limestone fertilizer production line has the character of less investment, quick results and good economic benefits The whole equipment process is compact, scientific and advanced Energy saving and consumption reducing, no waste removal, stable operation, reliable running, convenient maintenanceLimestone Fertilizer Production LineLimestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcLimestone Crushing Equipment and Production LineGypsum Powder Production Line; Superphosphate Production line; such as limestone, dolomite, and chalk, which are calcined at 10001100°C We can provide technological solutions and complete production equipment for 50 Active Lime Production Line

.jpg)

Limestone Powder Production Line, Limestone Grinding plant, Limestone

Limestone powder production line is a complete powder grinding system, including jaw crusher Equipment: Jaw crusher, Bucket Elevator, Raymond Mill, Dust desulfurization, building materials, medicine and other industries Quicklime becomes slaked lime by absorbing moisture or adding water The main component is Product: Lime Production Plant Capacity: 50 – 1200 TPD FUEL: Coal Gas, Natural Gas, and Pulverized Coal Application: Active Lime Production Line/ Quicklime Production Line/ Hydrated Lime Production Line Main Equipment for Lime Production Line: Rotary Lime Kiln / Vertical Lime Kiln, Raymond Mill, Jaw Crusher, Bucket Elevator, Separator, Dust Collector, etcLime Production Line for HighOutput Lime Production Plant2024年4月16日 One of the biggest pieces of equipment you’ll need in making quicklime is a stove or kiln Your stove or kiln should be up to the task of cooking the amount of quicklime you intend to make Your kiln needs to be able to maintain high temperatures (over 1000 degrees Celsius) for up to an hourHow to Make Quicklime: 10 Steps (with Pictures) wikiHow2024年1月23日 If a powder form is needed, limestone particles are transported to a limestone grinding mill via a conveyor belt system for the final fine grinding Sandmine Machinery has the whole limestone processing equipment, contact with us to get professional solution 450TPH Limestone Gravel Production Line in Mexico;Limestone crushing and screening production line introduction

limestone grinding mill, limestone grinding machine,

Limestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly Advanced Active Lime Production Line Equipment Calcination Of Limestone, High Active Quick Lime Plant Processing Limestone To Quicklime $50,00000 $300,00000 Min order: Professional Air Swept Coal Mill/Coal Grinding Machine/Ball Mill For Coal Powder $10,00000 $200,00000 Min order: 1 setAdvanced Active Lime Production Line Equipment Calcination Of LimestoneThis equipment solves problems that lead to poor stone shapes resulting from traditional equipment production With a high quality, uniform granularity, excellent stone shape and low stone powder output rate, the finished product Lime Production Line Limestone Equipment 2023年2月2日 Quick Lime (CaO) or calcium oxide, is a white or gray powder material that is applied for industries such as industrial and environmental applicationsQuicklime has various grades that are applied for differing applications In this article, we are going to take a further look at what is quicklime, its properties, its applications or uses, its types or grades its importance What Is Quick Lime? Types, Properties, And Uses Tradeasia

Process flow of hydrated lime production line Gaifeng

2022年3月16日 The hydrated lime production line is to crush the qualified hydrated lime blocks to a particle size of about 40mm by the jaw crusher, and send them to the hydrated lime storage tank silo through the bucket elevator The digester performs preliminary digestion When the hydrated lime completes the primary digestion, it enters into the Ⅱlevel digestion or the Ⅲ SOLUTION2: Lime Production Line With Vertical Kiln The vertical lime kiln is suitable for smallcapacity active lime production lines, lowcost, safe and environmentally friendly The vertical lime kiln uses the principle that the material’s own weight descends and the hot gas rises for heat exchange to burn lime We supply twin shaft lime kiln, double beam lime kiln, annular lime kiln Lime Production Line Active Lime Production Line Cement Vertical preheater Vertical preheater is one of the main active lime equipment, the main effect of vertical preheater is the limestone material sent to the preheater, and use high temperature exhaust gas from the kiln calcining out emissions(1150 degrees Celsius), the material in the preheater evenly heated to about 900 degrees CelsiusIn the preheating process of 600 tons of active lime production line equipmentLimestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone

.jpg)

Sigma Minerals

We are the first ISO 9001 and the only ISO 14001 Hydrated Lime and Quick Lime manufacturing company in India Hydrated Lime 3 Quick Lime Powder 4 Conventional Quick Lime 5 Limestone We Promise We are Self –Motivated We are passionate about our work Conventional Quick Lime; Crushed Limestone; Quality Assurance; SIGMA SOLUTIONS 2020年3月7日 Limestone, a kind of natural mineral resource, is a sedimentary rock formed by inorganic remains such as shells or bones And people always see it in warm and shallow water fields We all know that the main ingredient of limestone is calcium carbonate but sometimes it may also contain magnesium, iron or manganese affecting the Read MoreLimestone Limestone Powder: Uses, Price and Production HongXing Quicklime A monoxide of calcium (CaO), is often referred to as burnt lime It is a white, caustic, alkaline, crystalline solid and manufactured from limestone, which is extracted from quarries and mines Limestone is usually crushed and fed QUICK LIME SHC Group Vietnam SHC Techmicom2022年4月20日 Lime is divided into quick lime and slaked lime After being calcined, limestone becomes calcium oxide CaO (commonly known as quicklime), which is generally in the form of lumps and is used in water quality treatment, Limestone crushing and grinding production line

Limestone crushing technology and equipment SBM

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and 2020年7月17日 It is vital in the production of countless materials Lime, or calcium oxide (CaO), is derived from high quality natural deposits of limestone, or calcium carbonate (CaCO3) Limestone is a sedimentary rock that formed millions of years ago as the result of the accumulation of shell, coral, algal, and other ocean debrisWhat is Lime: Lime vs Limestone Mintek Resources2024年8月14日 Great! Let’s continue with Section 2, where we’ll dive into the Coating Equipment Production Line This section will explore the machinery and systems that play crucial roles in the powder coating process Section 2: Coating Equipment Production Line Section 2: Coating Equipment Production LineCoating Equipment Production Line Powder Coating EquipmentActive Lime Production Line Capacity : 502000t/d Applicable Materials : limestone, dolomite, chalk, etc Applications: steel smelting, chemical industry and power plant desulfurizatiol and other fields Case Description: The active lime production line is a kind of equipment and process used to produce active limeActive Lime Production Line Hongji Mining Machinery

Quick Lime Powder

Quick Lime Powder Quick Lime Powder also known as Calcium oxide (CaO) or burnt lime, is a chemical compound that is widely usedIt is a caustic, white, alkaline, crystalline solid at room temperature The term "lime" refers to calciumcontaining inorganic materials that primarily consist of carbonates, oxides, and hydroxides of calcium, silicon, magnesium, aluminum, and ironWe use stateoftheart equipment to process the limestone into a fine powder within the Khinwsar Tehsil, our advanced manufacturing plant boasts impressive capacities: 90 TPD for Quick lime powder and 150 TPD for Hydrated Lime Powder Limestone powder is used as a raw material in the production of ceramics, such as tiles, bricks, Limestone Powder Suppliers in India: Quality Limestone PowderAt Calmine India Pvt Ltd, we are committed to providing the highest quality limebased products to our customersWe are a leading manufacturer of Quick Lime Lumps, Hydrated Lime Powder, Quick Lime Powder, and Lime Stone, all of which are produced using stateoftheart technology and the finest natural materialsCalmine India Pvt LtdLimestone in the preheater will be preheated by the hot air, then it will be discharged to rotary kiln through chute that connecting preheater and kiln, it will stay in the kiln for 152 hours for calcination, during the process, it will be calcinated with temperature around 1300 ℃, after which comes limestone decomposition and release of co2,then the for mation of quick lime qill be Active Lime Production Line