How to process heavy calcite ore

How calcite is mined and processed

Calcite mining and processing involve several steps to transform raw calcite into usable materials Here’s an overview of the typical process: Geologists conduct surveys to locate calcite deposits Various techniques, including satellite imagery and core sampling, are used to evaluate the 2020年12月1日 Calcite ores typically contain metal sulphide, silicate, or other calciumcontaining impurity minerals, which can be removed by flotation A tremendous amount of research has been performed onAn Overview of Calcite Recovery by Flotation2023年8月26日 Gold production refers to the process of extracting gold from its ore or deposits and refining it to obtain pure gold Here are some key points related to gold production: Mining : Gold is typically mined from goldbearing Gold : Mineral Properties, Formation, Mining, The primary methods used to extract minerals from the ground are: Underground miningSurface (open pit) miningPlacer mining The location and shape of the deposit, strength of the rock, ore grade, mining costs, and current market price How do we extract minerals? US Geological Survey

.jpg)

How calcite is mined and processed

Here’s an overview of the typical process: Exploration and Site Selection: Openpit mining is the most common method employed for calcite extraction Heavy machinery such as bulldozers and frontend loaders are used to remove overburden (the surface material covering the 2023年2月15日 Hematite, also spelled haematite, is a weakly magnetic iron ore with better floatability than magnetite and wide distributionIt is one of the most important raw materials for the extraction of iron Its composition is complex In addition to containing a small amount of magnetite, the impurity embedding of haematite has uneven particle size and high content of How to Extract Iron from Hematite: Methods and PlantsHeavy oil is a liquid produced by refining crude oil in an oil refinery or extracted in Fulgora using an offshore pumpIt can be processed into light oil, solid fuel and lubricantIt is more efficient to process heavy oil into light oil before creating solid fuel from it It can also be used as ammo in flamethrower turrets Heavy oil can be obtained on Vulcanus using Simple coal liquefactionHeavy oil Factorio Wiki2024年5月16日 Jaw CrusherPrimary Crusher Process: Feeding: Large chunks of calcite, as extracted from the mines, are fed into the jaw crusher Action: The jaw crusher consists of two jaws, one fixed and the other movingThe moving jaw exerts a compressive force on the calcite, breaking it into smaller pieces Output: The output from the jaw crusher is in the range of 6 to How To Make Calcite Powder?Calcite Powder Manufacturing Process

.jpg)

82: Mining and Ore Processing Geosciences LibreTexts

Media Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using openpit mine methods (Figure 815 in Section 81)Creating a giant hole in the ground is generally cheaper than making an underground 2023年10月27日 Ilmenite is the most important titanium ore It is often used for the production of the metal titanium and titanium dioxide (FeTiO 3) accessory products, such as paint, paper, titanium white (white pigment), plastics, fabrics, etc This blog will introduce the ilmenite beneficiation process and processing plantIlmenite: An Ore of Titanium Beneficiation and Plant2020年9月23日 In general, precipitated calcium carbonate (PCC) is used as a mineral filler in paper industries; while natural calcite (CaCO3) ore is also suitable for industrial use if it is a finely ground highgrade material Naturally, calcite is found in the form of high or lowgrade ores and it is one of the most widely distributed industrial minerals on the earth’s crust However, it is An Overview of Calcite Recovery by Flotation2022年6月25日 It’s an essential tool if you are looking for fluorite, calcite, and scheelite (tungsten ore) A hand lens A hand lens allows you to check the form (habit) of tiny crystals and identify them (for example, uvarovite garnet) or to check if faceted gemstones have Easy StepbyStep Mineral Identification (Expert Explains)

.jpg)

How to Process LeadZinc Ore by Gravity and Froth

2023年5月17日 Lead and zinc are relatively important nonferrous metals, often coexisting to form polymetallic deposits Leadzinc ore is a kind of mineral resource rich in lead and zinc In nature, there are about 250 types of lead 2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove Mining and Beneficiation of Phosphate Ore2024年8月1日 Calcitefluorite ores primarily consist of fluorite and calcite (with calcite content often exceeding 30%), with minor amounts of quartz, forming quartzcalcitefluorite ores Due to the similar surface physicochemical properties of calcite and fluorite, which are both calciumcontaining minerals, mutual transformation between these minerals can occur when they How To Process CalciteFluorite Ore ? Flotation Case Henan 2023年9月8日 For example, it can react with carbon monoxide (CO) to produce iron metal and carbon dioxide (CO2) in the process known as the reduction of hematite These chemical properties contribute to the unique behavior and applications of hematite in various fields, including industry, geology, and materials scienceHematite Properties, Formation, Uses, Occurrence Geology

.jpg)

Uranium ore Factorio Wiki

Uranium ore is a resource found on the map Instead of being smelted in a furnace, uranium ore must be processed in a centrifuge to produce uranium235 and uranium238, which is used to craft fuel for the nuclear reactor and in various types of ammunition Uranium ore is different from the other ores, as it requires sulfuric acid to be fed into the electric mining drill to mine it, at a Calcite is the mineral component of limestone which is used primarily as construction aggregates, and in production of lime and cement Limestone also is used in a variety of commercial applications including: road construction, riprap and jetty stone, filter stone, railroad ballast, poultry grit, mineral food, sugar processing, flux stone in steel production, glass manufacture, sulfur Calcite Processing Equipment, Process Flow, Cases JXSC Machine2024年11月21日 All rareearth ores contain less than 10 percent REO and must be upgraded to about 60 percent in order to be processed further They are first ground to a powder and then separated from the other materials in the ore body by various standard processes that include magnetic and/or electrostatic separation and flotation In the case of Mountain Pass Rareearth element Processing Ores BritannicaMany different mineral commodities are important to modern society However, when mineralogists think about mining, they are generally thinking of ore minerals that are the sources of important metals, or of minerals that have specific, highly valued properties (eg, asbestos, micas, potash, and gems of all sorts)That is what we will focus on in most of the rest of this 9 Ore Deposits and Economic Minerals – Mineralogy

Calcite, limestone and marble Earth Sciences Museum

If rain water, circulating downward through the rocks above a cavern, dissolves some calcite along the journey, it may drip from the roof of the cave As it reaches the air it evaporates; and when it does, calcite is deposited By a slow process stalactites are formed and elongated2024年11月21日 Each step in the process plays a vital role in separating fluorspar from impurities such as quartz, calcite and barite Next, we mainly introduce four common types of fluorspar mineral processing methods, Four Common Types Of Fluorspar Mineral Processing Calcite Production The major steps for Calcite production are as mentioned below: Step 1: Crush the incoming minerals and transfer them to ball mills to convert them to powder form Step 2: Sieve the powder form and separate it into the desired grades Step 3: Split the powder in 3micron, 5micron, 10 micron bags as required The important fact is that with 100 tonnes of Calcite Occurrence, Formation, Formula, Properties and Useswhen process water temperatures dropped to below 15° C At that time, the only available solution for improving performance at lower temperatures was heating the process water to above 15° C, resulting in high energy costs The customer also had to constantly adjust the fatty acid dosage to deal with changes in ore quality SolutionFlotation collectors Nouryon

.jpg)

Phosphate Rock Processing: 6 Useful Ways and 4 Stages

2023年8月8日 Process 1: Desliming Principle: Phosphate rock often adheres to wet ore mud Water washing removes the mud on the surface and separates fine ore particles, such as clay ore and finegrained quartz It can also remove certain soluble substances, such as sodium chloride Applicable type: Weathered or mudrich phosphate rock Process 2: FlotationIron ore is a resource found on the map It can be smelted into iron plates in a furnace, and is also a component in concrete Alternate gathering In the Space Age expension you can also gain iron ore on space platforms due gathering metallic asteroid chunks with asteroid collectors and process them in crushersIron ore Factorio Wiki32 Formation of Minerals Minerals form when atoms bond together in a crystalline arrangement Three main ways this occurs in nature are: 1) precipitation directly from an aqueous (water) solution with a temperature change, 2) crystallization from a magma with a temperature change, and 3) biological precipitation by the action of organisms 321 Precipitation from aqueous 3 Minerals – An Introduction to Geology2024年1月15日 Occasionally, specimen dealers call Cuprite, red copper ore It’s a soft, yet heavy, red oxide mineral that’s a major ore of copper Cuprite crystals are transparent to translucent and have a metalliclooking sheen but when you put a light behind it, magic happensHow To Identify Cuprite Like a Graduate Gemologist

Iron processing Definition, History, Steps, Uses, Facts Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive2024年11月24日 Every ore in the game will have a different "optimal" route for your run and base needs This may also change over time As a result, you want ore processing systems to be flexible allowing different ores to go on different routes You also want to be able to automatically pull out things at any step of the processOre Processing Concepts GT New Horizons2023年9月5日 The gravity separation process is a method that uses gravity difference to separate barite ore It is based on the density difference between barite and gangue minerals The specific gravity of barite is 4246, while the particular gravity of gangue minerals such as quartz and calcite is 2628General Process Introduction Of Barite Beneficiation2023年8月26日 Gold production refers to the process of extracting gold from its ore or deposits and refining it to obtain pure gold Here are some key points related to gold production: Mining : Gold is typically mined from goldbearing Gold : Mineral Properties, Formation, Mining,

How do we extract minerals? US Geological Survey

The primary methods used to extract minerals from the ground are: Underground miningSurface (open pit) miningPlacer mining The location and shape of the deposit, strength of the rock, ore grade, mining costs, and current market price Here’s an overview of the typical process: Exploration and Site Selection: Openpit mining is the most common method employed for calcite extraction Heavy machinery such as bulldozers and frontend loaders are used to remove overburden (the surface material covering the How calcite is mined and processed2023年2月15日 Hematite, also spelled haematite, is a weakly magnetic iron ore with better floatability than magnetite and wide distributionIt is one of the most important raw materials for the extraction of iron Its composition is complex In addition to containing a small amount of magnetite, the impurity embedding of haematite has uneven particle size and high content of How to Extract Iron from Hematite: Methods and PlantsHeavy oil is a liquid produced by refining crude oil in an oil refinery or extracted in Fulgora using an offshore pumpIt can be processed into light oil, solid fuel and lubricantIt is more efficient to process heavy oil into light oil before creating solid fuel from it It can also be used as ammo in flamethrower turrets Heavy oil can be obtained on Vulcanus using Simple coal liquefactionHeavy oil Factorio Wiki

How To Make Calcite Powder?Calcite Powder Manufacturing Process

2024年5月16日 Jaw CrusherPrimary Crusher Process: Feeding: Large chunks of calcite, as extracted from the mines, are fed into the jaw crusher Action: The jaw crusher consists of two jaws, one fixed and the other movingThe moving jaw exerts a compressive force on the calcite, breaking it into smaller pieces Output: The output from the jaw crusher is in the range of 6 to Media Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using openpit mine methods (Figure 815 in Section 81)Creating a giant hole in the ground is generally cheaper than making an underground 82: Mining and Ore Processing Geosciences LibreTexts2023年10月27日 Ilmenite is the most important titanium ore It is often used for the production of the metal titanium and titanium dioxide (FeTiO 3) accessory products, such as paint, paper, titanium white (white pigment), plastics, fabrics, etc This blog will introduce the ilmenite beneficiation process and processing plantIlmenite: An Ore of Titanium Beneficiation and Plant2020年9月23日 In general, precipitated calcium carbonate (PCC) is used as a mineral filler in paper industries; while natural calcite (CaCO3) ore is also suitable for industrial use if it is a finely ground highgrade material Naturally, calcite is found in the form of high or lowgrade ores and it is one of the most widely distributed industrial minerals on the earth’s crust However, it is An Overview of Calcite Recovery by Flotation

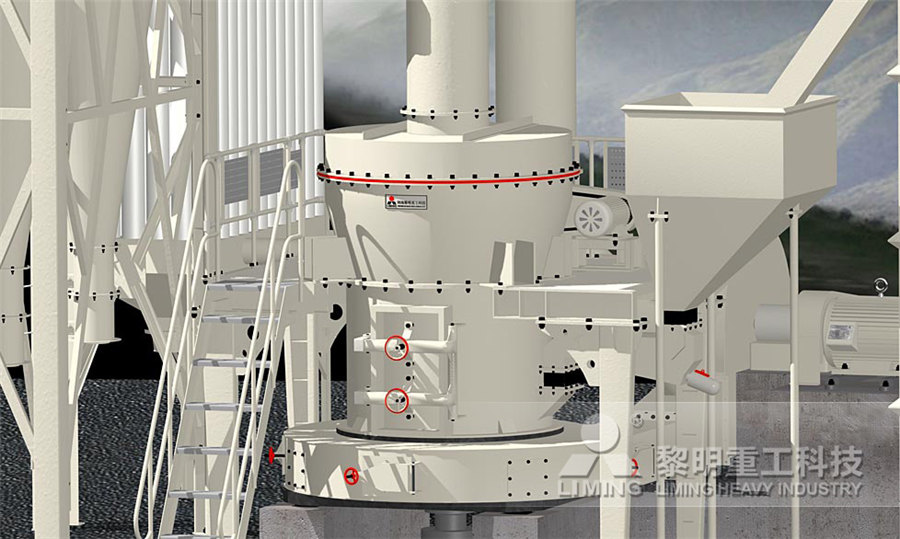

制粉项目-2023.11.17.jpg)

Easy StepbyStep Mineral Identification (Expert Explains)

2022年6月25日 It’s an essential tool if you are looking for fluorite, calcite, and scheelite (tungsten ore) A hand lens A hand lens allows you to check the form (habit) of tiny crystals and identify them (for example, uvarovite garnet) or to check if faceted gemstones have