S155 system ore mill

.jpg)

300M/S155 High Performance Alloy Steel Available from NeoNickel

300M/S155 is a high performance alloy steel which is a vacuum melted grade, supplied in the normalised and tempered/softened condition to enhance machinability prior to final heat IsaMill™ uses horizontal milling to secure better energy efficiency, product size and availability The IsaMill™ has realworld success in 143 metalliferous installations across 23 countries It’s IsaMill™ Glencore Technology2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral Processing The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant Mills for minerals and ores Loesche

S155 Steel S155 Steel Bar

BS S155 in the British Standard Aerospace Series is a NickelSilicon–Chromium–Molybdenum–Vanadium through hardening steel with a tensile strength of BS S155 is the British aerospace equivalent of US steel grade 300M (4340M / AMS 6257) It is a vacuum melted grade supplied in the normalised and tempered/softened condition to allow for Hardenable Steel BS S155 Aircraft MaterialsThe Copper Mountain SAG mill is 10363 mm [34 feet] in diameter and 6096 mm [20 feet] long It is a grate discharge mill with an inside diameter of 10363 mm [34 feet] and a grinding length of Paper # 25 Copper Mountain Overview on the Grinding Mills and 2024年5月14日 RME Advanced Technology Mill Relining System RME has focused on delivering this improvement through new mill relining technologies and robotics which enable Higher performing liners + fast relining = higher throughput

.jpg)

Semiautogenous mill liners: Designs, alloys, and maintenance

In spite of initial difficulties, large autogenous and semiautogenous mills have reached an acceptable level of technology that provides the mineral engineer with a reliable, low cost SemiAutogenous Grinding mills can be optimized for maximum ore throughput or maximum grinding energy efficiency In both cases, precise control of the mill weight is critical Model SAG Mill Optimization using Model Predictive Control AndritzSAG AND BALL MILL EFFECTS FROM ORE SORTING SYSTEM IMPLEMENTATION *J Starkey1,2, B Hilscher1, S Reeves1, and J Hedderson1 1SacréDavey Engineering 212 151 Randall Street Oakville, Canada L6J 1P5 Corresponding author: 2Starkey Associates IncSAG AND BALL MILL EFFECTS FROM ORE SORTING SYSTEM 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911Metallurgist

The transitional change on the implementation of

2017年9月1日 The transitional change on the implementation of iso 14001: 2015 in Copper Ore Mill Case study September 2017; Journal of Ecological Engineering 18(5) system at copper ore mill:Ball mill process control system using ACS (Adaptable Control System) Figure 2 shows that the input and output signals depend mainly on the mill and the hydrocyclone Some malfunctions occur as a result of system disturbances that occur during the processes that take place at the entrance and exit of ore to the mill (including the hydrocyclone Control of ball mill operation depending on ball load and ore Kienko, L A, Voronova, O V, Kondrat’ev, S A (2017) Prospects for ReProcessing Of Carbonate–Fluorite Ore Mill Tailings at Yaroslavsky Mining CompanySciHub Prospects for ReProcessing Of Carbonate–Fluorite Ore Mill 2019年8月29日 Sensor‐Based Ore Sorting Technology in Mining—Past, Present and Future(PDF) Sensor‐Based Ore Sorting Technology in Mining—Past,

.jpg)

Gold and Tailings: The Standard Mill at Bodie, California

When examining industrial facilities, industrial archaeologists often pay greater attention to the facilities' products than they do to the facilities' byproducts Nevertheless, paying close attention to byproducts is an important facet of making an industrial facility profitable This articl examines the Standard mill, a turnofthe20thcentury facility for treating gold ores at Bodie SBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Our main products include ultrafine vertical roller mill, ultrafine grinding mill highquality ore grinding equipment, and perfect service system The main products include: ore stone crushers (jaw crushers, cone crushers, hammer crushers, etc), ore grinding SBM Ultrafine Powder Technology Industrial Grinding Mill, The modernization project includes two 8 MW SAG (semiautogenous) mills and two 97 MW ball mills with dual pinion drives The new drive systems are replacing the existing synchronous motors and direct converters for the SAG mills and the drive systems of the ball mills, which were installed by a different manufacturerSiemens modernizes drive system for ore mills in Chile2018年3月1日 This paper elaborates on the development of paste backfill using mill tailings generated during the processing of a uranium ore deposit hosted in dolomitic limestone(PDF) Mill tailings based composites as paste backfill in mines

(PDF) Towards waterless operations from mine to mill

2022年9月1日 A conceptual diagram with considerations for selecting minetomill ore bene ciation technologies with lowwateruse or fragmentation in the whole size reduction system from drilling 2013年4月1日 A simple and novel nonlinear model of a runofmine ore grinding mill circuit, developed for process control and estimation purposes, is validatedAnalysis and validation of a runofmine ore grinding mill circuit DOVE Rod Mills are supplied in a wide range of capacities and specifications DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr – 20 Kg/Hr) For small to large scale Rod Mills Grinding Mills DOVEABB was recently contracted to supply gearless mill drive (GMD) systems for two 38 foot semiautogenous grinding (SAG) mills at the Serra Azul iron ore mine in Brazil The Serra Azul mine unit, owned by MMX Mineração e Metálicos, an EBX Group company, is located in the iron quadrangle of Minas Gerais, next to Belo Horizonte – the heart of the Brazilian mining stateGearless mill drive system in iron ore processing

Making remote mines and low ore grades economical and shifting

A milling circuit is a complex, multivariable interacting system Dynamically changing ore conditions and wear parameters pose particular problems for grinding controllers By integrating data, the automation system optimizes grinding controls, avoiding the 2023年10月17日 Type of Ore powder grinding mil 1 Raymond mill Raymond mill feed particle size ≤30mm, production capacity 8176 tons/day, production fineness 80325 mesh, the main transmission device adopts sealed gearbox and pulley, and other Compared with the ore grinding mill, the screening rate is higher, and the screening rate is as high as 99%How to choose a suitable ore powder grinding mill?Metcom Technologies, Inc 501 South Pokegama Ave, Suite 6 Grand Rapids, MN 55744 USA Phone: 2182124350 Fax: 9896696000 info@metcomtechPublished Wins – Metcom Technologies2011年11月16日 Spengler et al (1998) took ecological, technical and economic aspects into account and developed a multicriteria DSS, which is a combination of process models simulated with a flowsheeting program Li et al (2000) proposed a modelbased method for a production plan and schedule in the iron and steel industry They designed a DSS in terms of the A knowledgebased multirole decision support system for ore

12th Mill Operators' Conference 2014 AusIMM

It is normalised based upon the ore resistance to breakage, so it provides feedback about the health' of the milling process under varying operating conditions and ore types Mill grinding efficiency is measured at the same time as CSE through circuit samplingFunctional performance analysis combines CSE and mill grinding efficiency to provide 911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911MetallurgistSAG Mill Optimisation and Increasing Throughput at the Phu Emphasis on competent ore Discharge system type Radial Curved Radial Grate Open Area / aperture, %/mm 145 % / 25 mm 145 % / 25 mm 156% / 30 mm Total mass limit, t 1200 Total liner package mass, t 485 610 480SAG Mill Optimisation and Increasing Throughput at the Phu2020年12月21日 Tumbling mills have been widely implemented in many industrial sectors for the grinding of bulk materials They have been used for decades in the production of fines and in the final stages of ore comminution, Increasing Energy Efficiency and Productivity of the

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Learn about the key stages in iron ore processing, including crushing, screening, and beneficiation techniques for optimal resource utilization +86 ; xlyin@ The choice of grinding mill depends on factors As a “onebox” instrument they contain the eluent pump, manual injector, column oven, autosuppressor unit (anion version only) and a conductivity detector The S 155 ion chromatographs are fully functional instruments, completed only with a Sykam S 155 IC Systems Sykam Chromatography2021年2月26日 Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational masses The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading One method for increasing the energy efficiency of ball mills is to optimize their drive systems This article Energy Efficiency Analysis of Copper Ore Ball Mill Drive ROM ore milling circuit for state and parameter estimation The paper also investigates the performance of dual estimation over simultaneous estimation through a sensitivity analysis and shows a comparison of the two estimation approaches 2 State estimation Consider the general statespace representation of a dynamic systemDual particle filters for state and parameter estimation with

Detecting SAG Ball Mill Labyrinth Seal Leaks Pall Corporation

problems in their large SAG Mill and Ball Mill lube systems with the detection of “Feed Chute” misalignment and “FlingRing” problems When “Feed Chutes” misalign or “FlingRing’s” do not deflect ore slurry away from the labyrinth seals, the ore slurry works it’s way into these seals and into the lube system2021年7月1日 In the study of Cleary [3], particles were modeled by the superellipsoids in 2D, and the influence of ball and rock shape on the charging behavior and power draw was initially exploredKiangi et al [26] combined experiments and simulation to conduct similar research in a 3D millFurthermore, Xu et al [35] used a 3D superellipsoid model in a SAG mill to DEM investigation of SAG mill with spherical grinding media The ball mill grinding process is mainly composed of a ball mill, a hydrocyclone cluster, a sump, a slurry pump and an ore bin The schematic diagram of this process is shown in Fig 1 Fig 1 Schematic diagram of ball mill grinding process The variables of this process shown in Fig 1 are explained as follows: WIntelligent optimal control system for ball mill grinding processPDF On Jan 1, 2018, Edoardo Ales published ILO Convention 155 Occupational Safety and Health Convention, 1981 (No 155): ArticlebyArticle Commentary Find, read and cite all the research you (PDF) ILO Convention 155 Occupational Safety and Health Convention

SAG AND BALL MILL EFFECTS FROM ORE SORTING SYSTEM

SAG AND BALL MILL EFFECTS FROM ORE SORTING SYSTEM IMPLEMENTATION *J Starkey1,2, B Hilscher1, S Reeves1, and J Hedderson1 1SacréDavey Engineering 212 151 Randall Street Oakville, Canada L6J 1P5 Corresponding author: 2Starkey Associates Inc2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911Metallurgist2017年9月1日 The transitional change on the implementation of iso 14001: 2015 in Copper Ore Mill Case study September 2017; Journal of Ecological Engineering 18(5) system at copper ore mill:The transitional change on the implementation of Ball mill process control system using ACS (Adaptable Control System) Figure 2 shows that the input and output signals depend mainly on the mill and the hydrocyclone Some malfunctions occur as a result of system disturbances that occur during the processes that take place at the entrance and exit of ore to the mill (including the hydrocyclone Control of ball mill operation depending on ball load and ore

SciHub Prospects for ReProcessing Of Carbonate–Fluorite Ore Mill

Kienko, L A, Voronova, O V, Kondrat’ev, S A (2017) Prospects for ReProcessing Of Carbonate–Fluorite Ore Mill Tailings at Yaroslavsky Mining Company2019年8月29日 Sensor‐Based Ore Sorting Technology in Mining—Past, Present and Future(PDF) Sensor‐Based Ore Sorting Technology in Mining—Past, When examining industrial facilities, industrial archaeologists often pay greater attention to the facilities' products than they do to the facilities' byproducts Nevertheless, paying close attention to byproducts is an important facet of making an industrial facility profitable This articl examines the Standard mill, a turnofthe20thcentury facility for treating gold ores at Bodie Gold and Tailings: The Standard Mill at Bodie, CaliforniaSBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Our main products include ultrafine vertical roller mill, ultrafine grinding mill highquality ore grinding equipment, and perfect service system The main products include: ore stone crushers (jaw crushers, cone crushers, hammer crushers, etc), ore grinding SBM Ultrafine Powder Technology Industrial Grinding Mill,

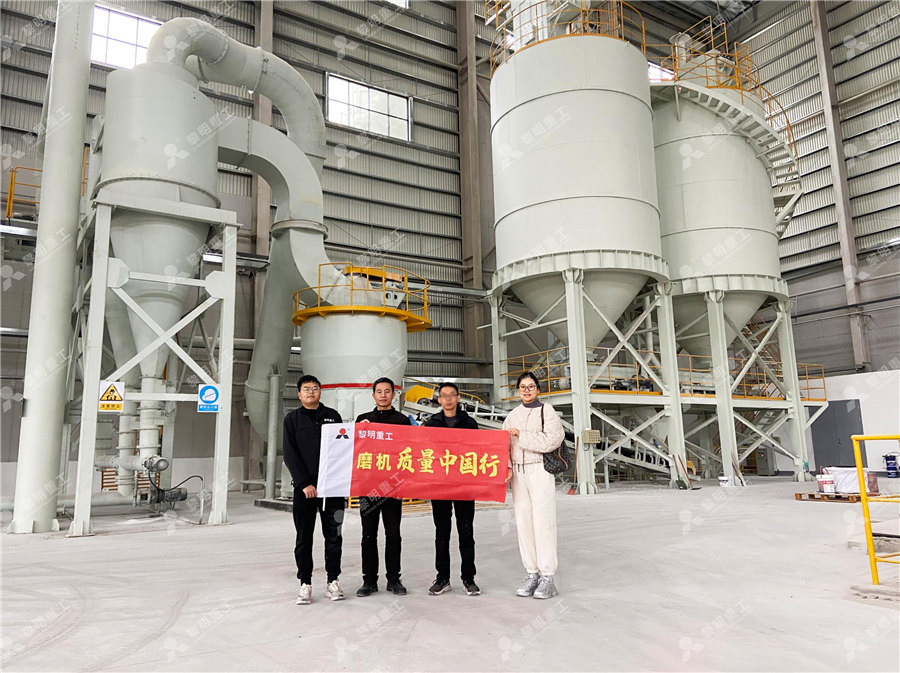

CFB石灰石脱硫剂制备64.jpg)

Siemens modernizes drive system for ore mills in Chile

The modernization project includes two 8 MW SAG (semiautogenous) mills and two 97 MW ball mills with dual pinion drives The new drive systems are replacing the existing synchronous motors and direct converters for the SAG mills and the drive systems of the ball mills, which were installed by a different manufacturer2018年3月1日 This paper elaborates on the development of paste backfill using mill tailings generated during the processing of a uranium ore deposit hosted in dolomitic limestone(PDF) Mill tailings based composites as paste backfill in mines