Magnetic separation calcite ore equipment production capacity

.jpg)

Magnetic Separation Plant Units

The Metso Magnetic Separation Plant Units consist of advanced magnetic separation process know how and equipment portfolio including SLon® Vertically Pulsating High Gradient Magnetic Separators (VPHGMS), Metso High Gradient Magnetic Separators (HGMS), and/or dry and This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the thirdstage fine crushing operation to reduce the High Pressure Grinding Roll and Magnetic Separation for Energy As the industry leader in technology and modularity, Metso Magnetic Separation Plant Units provide unrivaled selectivity, resulting in high recovery of fine and ultrafine particles and ease of execution Comprehensive portfolio Proven Magnetic Separation Plant Units MetsoFully variable electromagnetic field intensity (0–14 Tesla) giving the client the ability to adjust intensity for optimum separation Operator protection guards for a safer plant operation New Wet High Intensity Magnetic Separator Mineral Technologies

.jpg)

Development of a centrifugal dry magnetic separator for

2024年3月15日 A novel fullscale centrifugal dry magnetic separator (cDMS) was developed, and in this investigation, it was used to process a fine magnetite ore, which assays 2857% Fe 2023年12月1日 Utilizing magnetic separation is an important step towards achieving green and lowcarbon steel production In China, every 1% increase in iron ore concentrate grade Developing high gradient magnetic separators for greener 2022年9月9日 Dry magnetic separation is a technology that sorts magnetic minerals from gangue using air as the medium instead of water When raw ore is fed to the magnetic separator, the magnetic particles are subjected to Dry Permanent Magnetic Separator: Present Status and 2022年1月1日 Development of large magnetic separator units can increase the ore treating capacity, reduce energy consumption, and save space The largest permanent magnetic drum Physical separation of iron ore: magnetic separation ScienceDirect

CFB石灰石脱硫剂制备96.jpg)

Magnetic Separation: Principles, Devices, and

2023年10月30日 Magnetic separation, thanks to its advantages of large processing capacity, low operation cost, high efficiency and applicability, and environmental friendliness in comparison to other separation methods, can be 2021年2月2日 ENRICHMENT OF APATITEBEARING IRON ORE BY MAGNETIC SEPARATION AND FLOTATION the raw ore was ground below 106 m size and then subjected to magnetic separation (Calcite and/or (PDF) ENRICHMENT OF APATITEBEARING IRON ORE Magnetic Separation 21 Introduction The differences in magnetic susceptibility can be utilized to separate a valuable mineral from its gangue through the magnetic separation method Similar to other materials, minerals are generally classified into three main categories, namely diamagnetic, paramagnetic, and ferromagneticChapter 2 Magnetic Separation SpringerThe efficiency of separation can often be represented with the formula:\[ \text{Efficiency} = \frac{\text{Mass of Magnetic Material Collected}}{\text{Total Mass of Magnetic Material in Initial Mixture}} \times 100\]Ensuring high efficiency requires careful calibration of the equipment and consideration of factors such as particle size, magnetic field strength, and the flow rate of Magnetic Separation: Process Techniques Vaia

.jpg)

Magnetic Separation Equipment SpringerLink

2024年1月1日 Magnetic separation equipment is widely used in the separation of magnetic minerals Lowintensity magnetic separator is mainly used for the separation of minerals with specific magnetic susceptibility greater than 1 × 10 −6 m 3 /kg, such as magnetite, vanadium titanomagnetite, pyrrhotite, and other minerals Mediumintensity magnetic separator is Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study A Jankovic and W Valery Metso Process Technology Innovation, PO Box 1028, Eagle Farm Qld, 4009, AustraliaMagnetite Iron Ore Design Case Study ResearchGateof second stage of magnetic separation on concentrate quality So, combination of two stages of magnetic separation and milling allowed us to produce magnetite concentrate with Fe total content of 68% and Fe mag recovery of 867% Nonmagnetic fraction of the first stage of magnetic separation is characterized by Fe total content of aboutRecovery of magnetitehematite concentrate from iron ore 2021年12月3日 of wollastonitecalcite ore was subjected to selfaerated Denver flotation equipment with a 15 L cell volume and a 1200 rpm mixing rate The conditions of the flotation tests are given(PDF) Extraction of Potassium from Feldspar by Roasting with

Guide to Magnetic Separation Eclipse Magnetics

Everything you need to know about magnetic separation in the food processing, Magnetic separators can be fitted at a variety of critical control points within the production line, inclduing silo intake, process equipment is often made from 304 or 316 stainless steel2021年1月8日 Abstract In this study the separation possibility of gangue minerals from a low grade magnetite ore with 45% Fe from an iron ore deposit located near ErzincanTurkey was investigatedENRICHMENT OF LOW GRADE MAGNETITE ORE BY MAGNETIC Magnetic separation Figure 2 shows a typical magnetic separation flowsheet comprising of Ball mill, LIMS and WHIMS Davis tube testwork To determine the percentage of ferromagnetic material in the sample, magnetic separation was conducted using an electromagnet Davis tube as depicted in Figure 2 The separation occurs byDevelopment of a physical separation preconcentration process Technological research was carried out by various concentration methods: Xray radiometric separation on the SRF1100L separator; dry magnetic separation on the PBS90/25 magnetic separator; gravity on the KCMD3 centrifugal concentrator and the SKL02 concentration table; flotation on the FMPL series flotation machines; wet magnetic separation on the DRY MAGNETIC SEPARATION OF MAGNETITE ORES ScienceGate

.jpg)

A discussion of magnetic separation techniques for

and dry magnetic separation DOBBINS, M, DOMENICO, J, and DUNN, P A discussion of magnetic separation techniques for concentrating ilmenite and chromite ores The 6th International Heavy Minerals Conference ‘Back to Basics’, The Southern African Institute of Mining and Metallurgy, 2007 A discussion of magnetic separation techniques for2023年5月12日 Magnetic separation is often placed before flotation Equipment recommended by Ftmmachinery: Magnetic separator Flotation separation Principle: Separation is carried out by utilizing the differences in the physical Magnesite Ore Processing: Separation and Calcination2024年1月1日 Conventional magnetic separation is to separate minerals according to their natural magnetism In addition, in some cases, in order to improve the efficiency of separation, it is possible to change the magnetism of minerals or take some special methods to make the mineral separation more effective, such as magnetization roasting and magnetic separation, Magnetic Separation SpringerLinkMinerals 2022, 12, 1251 4 of 20 Figure 1 Schematic diagram of CT series magnetic pulley structure 1—multipole magnetic system; 2—cylinder; 3—magnetic conductor; 4—belt [8]Dry Permanent Magnetic Separator: Present Status and

Magnetic Separators Processing Equipment Magquip

MAGQUIP has the production capability to manufacture up to 30 tons per month of finished capital equipment from our primary 5000 m² production facility We strive to work to the highest engineering and quality standards as set out by ISO 9001 Quality assurance and control is constantly managed via well trained QA/ QC / SHEQ management staffThe main factory is located at Kumbet and consists of 2 shaft 1 rotary kilns with a combined calcination capacity of >36,000 tpa of CCM, post processing facilities (ie crushing, screening, magnetic separation, mixing, milling, packing, storage, forwarding), offices, laboratory quality control, earthmoving equipment maintenance workshopCorporate Calcined Magnesite Production, CCM, Magnesium Therefore, magnetic separators should be installed at the beginning of the conveyor transport system Magnetic separators can typically be designed to retrofit on any existing conveyor system, without the necessity of relocating major equipment Magnetic separators are also used in combination with metal detectors to offer complete peace of mindMagnetic Separators Process Equipment Kinder AustraliaThe magnetic field attracts magnetic particles, whereas nonmagnetic materials are repelled because of magnetic, gravitational, centrifugal, and other forces The thickness of the belt should be about 02 mm, permitting the particles to be close to the surface of the magnetMagnetic Separation SpringerLink

.jpg)

Recent process developments in beneficiation and metallurgy of

2024年4月1日 Therefore, considerable energy is consumed to drive off all moisture prior to electrostatic separation, and the use of electrostatic separation in industrial production is relatively limited 49, 50 In general, the vast majority of beneficiation processes is combination of gravity separation, magnetic separation, and froth flotation 42010年10月6日 As a result of dry magnetic separation at about 750 Gauss magnetic field conducted with 0212+0106 mm size fraction under optimum conditions, a magnetite concentrate assaying 5441% Fe was Production of Heavy Media Quality Magnetite Concentrate 2017年1月1日 Finally, the magnetic component of the roasted ore can be recovered by magnetic separation after being liberated from gangue minerals Many pilotscale suspension magnetizing roasting and magnetic Recovery and separation of iron from iron ore using magnetic separation Dry Magnetic Separation of Iron Ore: There are many inherent advantages in processes that utilize dry magnetic separation to beneficiate iron ore Wet concentration of magnetite ore, in comparison, re quires 500 to 1000 gal of water per ton of concen trate produced This means extensive use of waterADVANCES IN MAGNETIC SEPARATION OF ORES 911

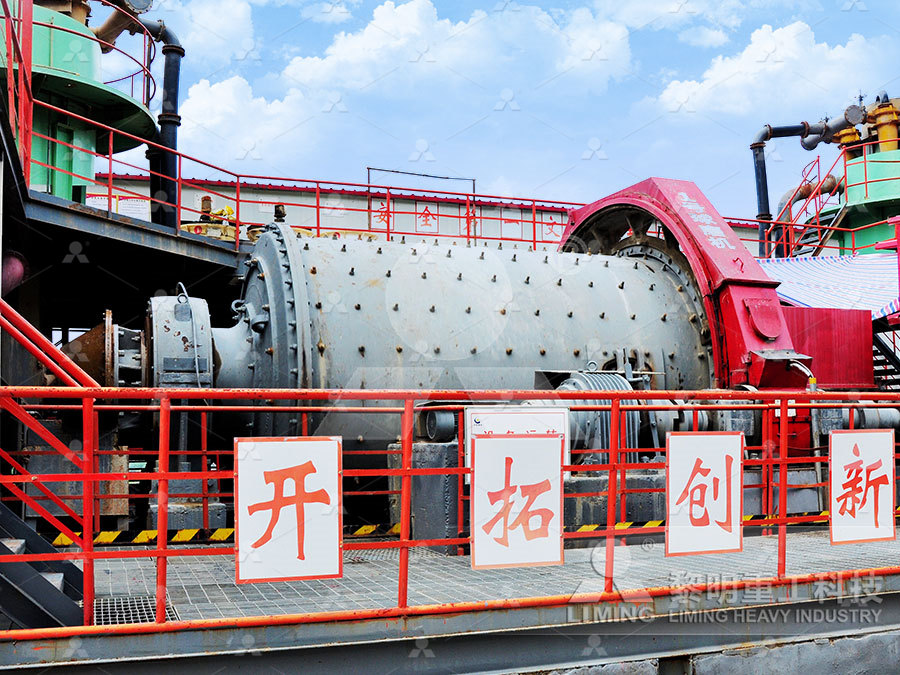

Magnetite Separation Production Line Yantai Jinpeng Mining equipment

Introduction Application Magnetite Separation Production Line is used to single magnetite with simple ore properties Process introduction Weak magnetic – reverse flotation process : it`s a process that divides into weak magnetic – positive ion reverse flotation process and weak magnetic –negative ion reverse flotation process , the difference is the reagent , negative ion RECENT ADVANCES IN MAGNETIC SEPARATOR DESIGNS AND APPLICATIONS 63 Existing technology Magnetic separation equipment for minerals processing generally falls into three basic categories: low, medium and high intensity, based on the relative magnetic field strength employed to accomplish separation Low intensity magneticRecent advances in magnetic separator designs and applicationsthe world, tungsten ore producing countries have increased their production by initiating steps to utilize the lowgrade complex tungsten ores Wolframite is the main mineral as a source of tungsten metal The most commonly used beneficiation methods for tungsten ores are gravity separation and magnetic separation, which are widely used in STUDY ON PRECONCENTRATION EFFICIENCY OF WOLFRAMITE FROM TUNGSTEN ORE The MAGNAROLL A Laboratory Benchtop Rare Earth Roll Magnetic Separator for Dry, Granular Weakly Magnetic Samples The MAGQUIP MAGNAROLL Benchtop Rare Earth Roll Separator is a permanent magnet highintensity roll magnet for the investigation, separation and or upgrading of dry granular paramagnetic material in the 75 microns to 10 mm size range This laboratory / MARC Technologies » Laboratory Magnetic Extraction Equipment

.jpg)

Jig Separator Gravity Separation of Tin Ore JXSC Mineral

2024年1月4日 It is a mineral processing jig used to process coarsegrained ore Skip to content JXSC Mineral Home; mining equipment production, and Tel: +86 EMail: mineral@jxsc Main Equipment Crushing Screening; Grinding Classifying; Gravity Separation; Magnetic Separation; Flotation Equipment; Gold Process 2013年9月16日 Although the majority of current steel production is supported by iron ore sourced from high0grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices EcoEfficient and CostEffective Process Design for Magnetite Iron Ore2021年2月2日 ENRICHMENT OF APATITEBEARING IRON ORE BY MAGNETIC SEPARATION AND FLOTATION the raw ore was ground below 106 m size and then subjected to magnetic separation (Calcite and/or (PDF) ENRICHMENT OF APATITEBEARING IRON ORE Magnetic Separation 21 Introduction The differences in magnetic susceptibility can be utilized to separate a valuable mineral from its gangue through the magnetic separation method Similar to other materials, minerals are generally classified into three main categories, namely diamagnetic, paramagnetic, and ferromagneticChapter 2 Magnetic Separation Springer

Magnetic Separation: Process Techniques Vaia

The efficiency of separation can often be represented with the formula:\[ \text{Efficiency} = \frac{\text{Mass of Magnetic Material Collected}}{\text{Total Mass of Magnetic Material in Initial Mixture}} \times 100\]Ensuring high efficiency requires careful calibration of the equipment and consideration of factors such as particle size, magnetic field strength, and the flow rate of 2024年1月1日 Magnetic separation equipment is widely used in the separation of magnetic minerals Lowintensity magnetic separator is mainly used for the separation of minerals with specific magnetic susceptibility greater than 1 × 10 −6 m 3 /kg, such as magnetite, vanadium titanomagnetite, pyrrhotite, and other minerals Mediumintensity magnetic separator is Magnetic Separation Equipment SpringerLinkReducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study A Jankovic and W Valery Metso Process Technology Innovation, PO Box 1028, Eagle Farm Qld, 4009, AustraliaMagnetite Iron Ore Design Case Study ResearchGateof second stage of magnetic separation on concentrate quality So, combination of two stages of magnetic separation and milling allowed us to produce magnetite concentrate with Fe total content of 68% and Fe mag recovery of 867% Nonmagnetic fraction of the first stage of magnetic separation is characterized by Fe total content of aboutRecovery of magnetitehematite concentrate from iron ore

.jpg)

(PDF) Extraction of Potassium from Feldspar by Roasting with

2021年12月3日 of wollastonitecalcite ore was subjected to selfaerated Denver flotation equipment with a 15 L cell volume and a 1200 rpm mixing rate The conditions of the flotation tests are givenEverything you need to know about magnetic separation in the food processing, Magnetic separators can be fitted at a variety of critical control points within the production line, inclduing silo intake, process equipment is often made from 304 or 316 stainless steelGuide to Magnetic Separation Eclipse Magnetics2021年1月8日 Abstract In this study the separation possibility of gangue minerals from a low grade magnetite ore with 45% Fe from an iron ore deposit located near ErzincanTurkey was investigatedENRICHMENT OF LOW GRADE MAGNETITE ORE BY MAGNETIC Magnetic separation Figure 2 shows a typical magnetic separation flowsheet comprising of Ball mill, LIMS and WHIMS Davis tube testwork To determine the percentage of ferromagnetic material in the sample, magnetic separation was conducted using an electromagnet Davis tube as depicted in Figure 2 The separation occurs byDevelopment of a physical separation preconcentration process