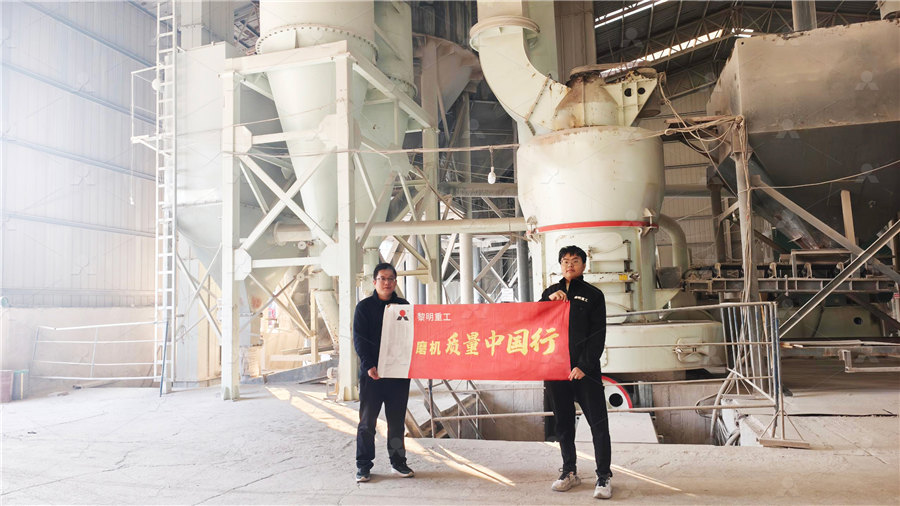

calcium carbide mud quicklime grinding production site

Recycling and utilization of calcium carbide slag ScienceDirect

2022年5月1日 CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are 2021年1月26日 To produce lime mud pHCC (pLHCC), only the ground lime mud was preflocculated first, calcium oxide was added next, and finally, carbon Application of In Situ Calcium Carbonate Process for Quicklime or Calcium Oxide (CaO), is an alkaline and crystalline solid utilized in several environmental and industrial applications Graymont can supply various types of quicklime in Quicklime Graymont2021年1月1日 Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO3) into quicklime (CaO) and carbon dioxide (CO2), also called (PDF) Natural and enhanced carbonation of lime in its different

.jpg)

Energy and exergy analysis of a new calcium carbide production

2022年2月1日 In the present study, the characteristics of calcium carbide production between ETM and GSM are compared In the traditional calcium carbide production process of ETM, 2021年10月4日 Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO 3) into quicklime (CaO) and carbon dioxide (CO 2), also called Natural and enhanced carbonation of lime in its different and stored on site • They are then sent to the customer by road, rail and even boats overseas a 7 Hydration • Sometimes after cooling, water is added to lime to make h ydrated lime • The A Competitive And effiCient Lime industry European Lime 2022年10月1日 In this review, the current state of the lime industry and its processing configurations is visualised This is followed by a detailed description of the current status of Decarbonising the lime industry: Stateoftheart ScienceDirect

Evaluation of calcium carbide residue and fly ash as sustainable

2024年1月5日 This study presents an indepth evaluation of calcium carbide residue and coal fly ash as alternative binders The assessment of raw materials emphasized their chemical 2024年4月30日 In order to overcome the defects of traditional strong alkaline activators and realise the high valueadded use of calcium carbide residue (CCR), this paper adopts CCR as Study on the Properties and Hydration Mechanism of Calcium The conversion of limestone into quicklime (calcium oxide) and slaked lime (calcium hydroxide Chemguide: Core Chemistry 14 16 The sediments might be mud or sand or the remains of sea creatures A metamorphic rock is one that has been changed by heat and pressure deep under the groundlimestone, quicklime and slaked lime chemguideThe main raw materials for the production of calcium silicate boards are: siliceous materials can be quartz sand, diatomaceous earth, fly ash, sand dust, porcelain clay, etc, calcareous materials can be raw lime powder, lime paste, lime powder, calcium carbide mud, etc, and reinforcing materials can be wood Paper fiber, wollastonite, glass fiber, mica powder, cellulose, organic Calcium Silicate Board Production Equipment Jiurui Machine

Calcium Carbide Structure, Properties, and Uses of CaC2

Production of Calcium Carbide – CaC 2 Production of calcium carbide in industries is as follows The mixture used is coke and lime; Temperature range is set at approximately 2,200 °C; The entire process is carried out in an electric arc furnace; This compound is widely used in the manufacture of calcium cyanamide and acetyleneDownload Citation On Oct 1, 2023, Qingxin Zhao and others published Investigation of various curing methods on the properties of red mudcalcium carbide slagbased artificial lightweight Investigation of various curing methods on the properties of red mud 2020年7月1日 Calcium carbide slag (CCS) is a solid waste generated in the acetylene (C 2 H 2 ) production process through a reaction of calcium carbide with water [7,8], with an annual emission of over 40 Utilization of carbide slaggranulated blast furnace slag system by 2023年10月19日 Industrial solid wastes red mud and calcium carbide slag are used to prepare lightweight aggregate ceramsite by coldbonded pelletizing technology in this study The effects of mixing water and curing method on the physical properties of ceramsite were investigated, including natural curing (in air at 20 °C), sealed curing, water curing, hot air oven curing, Investigation of various curing methods on the properties of red mud

Chemical compositions of calcium sulfoaluminate cement (CSA)

In this series of studies, coal gangue, calcium carbide slag, steel slag, dihydrate gypsum, and calcium carbonate were used synergistically to prepare lowcarbon cementitious material (LCCM) clinker2023年5月1日 The commercial alkali activators could account for more than 50% of the cost for producing geopolymersThus, to lower the carbon footprint of geopolymer by avoiding the utilization of energyintensive commercial alkali activators, a novel ecofriendly geopolymer was synthesized from 100% solid wastes comprising red mud (RM), calcium carbide slag (CS), Preparation and curing method of red mudcalcium carbide slag 2022年2月1日 Energy and exergy analysis is very useful to optimize the design, operation and evaluation of calcium carbide production process In this paper, a new calcium carbide production process of coalcokeelectricity grading substitution method (GSM) is proposed and evaluated by inter grating the first and second laws of thermodynamics according to the actual operation Energy and exergy analysis of a new calcium carbide production 2021年9月15日 Effects from ashforming elements on process performance have previously been discussed for cementproducing rotary kilns [7], [8], [9] and lime mud reburning kilns [10], and indications show that ashforming elements are part of the ring formation in quicklimeproducing rotary kilns [11]Ashforming elements, such as Si, Al, Fe and S, common in coal Coal ash and limestone interactions in quicklime production

Precipitated Calcium carbonate production,

2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on 2023年5月15日 The density of calcium carbide is 222 gram centimeter gram Chemical Properties of Calcium Carbide The chemical properties of calcium carbide are as followsCalcium carbide is nonvolatile Calcium carbide is Calcium Carbide: Definition, Preparation, Quicklime products (burnt lime, calcium hydroxide) are used in the chemicals industry, for example for the production of calcium carbide, propylene oxide, sodium carbonate and glycerine They are also used to produce lactates and lactic acids The Right Grinding Machines for Your Quicklime Industry2018年11月12日 Response FTIR spectra of CaO sample at (a) 700 °C, (b) 900 °C and (c) 1100 °C Figure 3a, b and c show the XRD diffractograms of the CaO samples at 700, 900 and 1100 respectively(PDF) Characterization of quicklime as raw material to hydrated

Calcium Carbide: Structure, Production, Properties and Uses

Calcium carbide, also known as calcium acetylide, has the chemical formula CaC 2 Its basic industrial application is the production of acetylene and calcium cyanamide Pure Calcium Carbide is an odorless and colorless solid; However, the technicalgrade calcium carbide compound pieces are either grey or brown; It comprises around 80 to 85% of CaC 2, Ca 3 N 2 (Calcium 2023年10月11日 Quicklime (Calcium Oxide) quicklime is one of many reagents offered by Mintek Resources Quicklime, also referred to as lime (calcium oxide (CaO)), is derived from high quality, natural deposits of limestone (calcium carbonate (CaCO3)) or dolomitic limestone (calcium magnesium carbonate (CaCO3 + MgCO3)Quick Lime Preparation, Properties and Uses Hebei Yayang 2016年4月1日 Calcium carbide residue (CCR) is a byproduct of acetylene gas production Stockpiles of CCR have continued to accumulate worldwide in many developed and developing countriesField Evaluation of Soft Highway Subgrade Soil Stabilized with Calcium PDF On Nov 15, 2015, NingJun Jiang and others published Multiscale laboratory evaluation of the physical, mechanical, and microstructural properties of soft highway subgrade soil stabilized Multiscale laboratory evaluation of the physical, mechanical, and

(PDF) Natural and enhanced carbonation of lime in its different

2021年1月1日 Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO3) into quicklime (CaO) and carbon dioxide (CO2), also called calcinationProduction of Calcium Carbide Calcium carbide is industrially produced in an electric arc furnace with a mixture of coke and lime, approximately at 2,200 °C (3,990 °F) This is an endothermic reaction that requires a high temperature to drive off the Calcium Carbide – Structure, Production, Uses and FAQs Vedantu2019年5月23日 Furthermore, the PVC production capacity using the calcium carbide route was 1919 million tons per year, which accounted for 82% of the overall production capacity of PVC There are around 81 production enterprises involved in generating carbide slag In 2015, the domestic overall production of calcium carbide was 265 million tons/prehensive Utilization of Carbide Slag SpringerLink2024年8月9日 A new type of ecological cementitious material was developed by using various solid waste materials to prepare lowcost and lowcarbon ecofriendly materials By incorporating circulating fluidized bed fly ash (CFBFA), red mud (RM), calcium carbide slag (CS), and ground granulated blast furnace slag (GGBS), the mechanical properties of the cementitious material Synergistic activation mechanism and longterm properties of a

.jpg)

Lime Briquette Machine FTM Machinery

At the same time, in the production of calcium carbide, quicklime briquettes can also be used instead of lumpy quick lime to smelt calcium carbide Application of lime briquette machine The calcium carbide production process has special Calcium oxide, also known as quicklime, is a white, of about 9001000°C in a lime kiln This process, known as calcination, releases carbon dioxide and leaves behind quicklime Processing and grinding the quicklime produces a fine powder for Used in the production of chemicals such as calcium carbide, calcium hypochlorite, and Quicklime (Calcium Oxide) CaO, Kemicalinfo2022年11月1日 Approaches for coping with the current challenges of energy shortages and environmental pollution are urgently needed (Li et al, 2018, Wang et al, 2019)Particularly, the production of calcium carbide (CaC 2) involves high reaction temperature (2473 K) and high power consumption (approximately 3500 kWh/t CaC 2)In 2020, the CaC 2 production Comparison of new twostep calcium carbide production 2018年6月1日 Another potential candidate for this process may be seen in carbide lime (CL), a waste generated during the acetylene gas (C 2 H 2 ) production process by the hydrolysis of calcium carbide (CaC 2 )Physical–Mineralogical–Chemical Characterization of Carbide Lime

.jpg)

Limestone crushing and grinding production line SBM Ultrafine

2022年4月20日 The processing of limestone is mainly to crush, classify and produce quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, etc Limestone generally adopts dry crushing process For limestone used in metallurgy and roads, the ore can be crushed and screenedHydrated lime and quicklime are both chemical compounds of calcium Calcium is called calcium hydroxide when it is present in its hydrated form, and it is called calcium oxide (or quicklime) in its pure state Calcium oxide is more reactive than hydrated lime and is also known to have a higher density When water is to powdered quicklime and Quicklime Preparation, Properties, and Applications with FAQsCarbide slag can be processed into powders by carbide slag milling machine, calcium carbide slag powders can be used to make cement instead of limestone, produce quicklime as raw material for calcium carbide, produce chemical products, make building materials, and use it for environmental treatment Carbide slag powder production line News Carbide Slag Grinding Plant HLM Vertical Mill2024年4月1日 As a calciumrich material, CCR has also been considered for the synthesis of various high valueadded chemicals, such as light/nano calcium carbonate (Chindaprasirt et al, 2023; Jimoh et al, 2016), calcium sulphate whisker (Wang et al, 2014), calcium carbide (Wang et al, 2022), feed grade calcium formate (Ca(HCO 2) 2) (Ma et al, 2016), and other chemicals Sustainable utilisation of calciumrich industrial wastes in soil

limestone, quicklime and slaked lime chemguide

The conversion of limestone into quicklime (calcium oxide) and slaked lime (calcium hydroxide Chemguide: Core Chemistry 14 16 The sediments might be mud or sand or the remains of sea creatures A metamorphic rock is one that has been changed by heat and pressure deep under the groundThe main raw materials for the production of calcium silicate boards are: siliceous materials can be quartz sand, diatomaceous earth, fly ash, sand dust, porcelain clay, etc, calcareous materials can be raw lime powder, lime paste, lime powder, calcium carbide mud, etc, and reinforcing materials can be wood Paper fiber, wollastonite, glass fiber, mica powder, cellulose, organic Calcium Silicate Board Production Equipment Jiurui MachineProduction of Calcium Carbide – CaC 2 Production of calcium carbide in industries is as follows The mixture used is coke and lime; Temperature range is set at approximately 2,200 °C; The entire process is carried out in an electric arc furnace; This compound is widely used in the manufacture of calcium cyanamide and acetyleneCalcium Carbide Structure, Properties, and Uses of CaC2Download Citation On Oct 1, 2023, Qingxin Zhao and others published Investigation of various curing methods on the properties of red mudcalcium carbide slagbased artificial lightweight Investigation of various curing methods on the properties of red mud

.jpg)

Utilization of carbide slaggranulated blast furnace slag system by

2020年7月1日 Calcium carbide slag (CCS) is a solid waste generated in the acetylene (C 2 H 2 ) production process through a reaction of calcium carbide with water [7,8], with an annual emission of over 40 2023年10月19日 Industrial solid wastes red mud and calcium carbide slag are used to prepare lightweight aggregate ceramsite by coldbonded pelletizing technology in this study The effects of mixing water and curing method on the physical properties of ceramsite were investigated, including natural curing (in air at 20 °C), sealed curing, water curing, hot air oven curing, Investigation of various curing methods on the properties of red mud In this series of studies, coal gangue, calcium carbide slag, steel slag, dihydrate gypsum, and calcium carbonate were used synergistically to prepare lowcarbon cementitious material (LCCM) clinkerChemical compositions of calcium sulfoaluminate cement (CSA) 2023年5月1日 The commercial alkali activators could account for more than 50% of the cost for producing geopolymersThus, to lower the carbon footprint of geopolymer by avoiding the utilization of energyintensive commercial alkali activators, a novel ecofriendly geopolymer was synthesized from 100% solid wastes comprising red mud (RM), calcium carbide slag (CS), Preparation and curing method of red mudcalcium carbide slag

.jpg)

Energy and exergy analysis of a new calcium carbide production

2022年2月1日 Energy and exergy analysis is very useful to optimize the design, operation and evaluation of calcium carbide production process In this paper, a new calcium carbide production process of coalcokeelectricity grading substitution method (GSM) is proposed and evaluated by inter grating the first and second laws of thermodynamics according to the actual operation 2021年9月15日 Effects from ashforming elements on process performance have previously been discussed for cementproducing rotary kilns [7], [8], [9] and lime mud reburning kilns [10], and indications show that ashforming elements are part of the ring formation in quicklimeproducing rotary kilns [11]Ashforming elements, such as Si, Al, Fe and S, common in coal Coal ash and limestone interactions in quicklime production