How many Shandong slag vertical mills are there

Slag Grinding Plant GGBS Plant Slag Mill, Slag

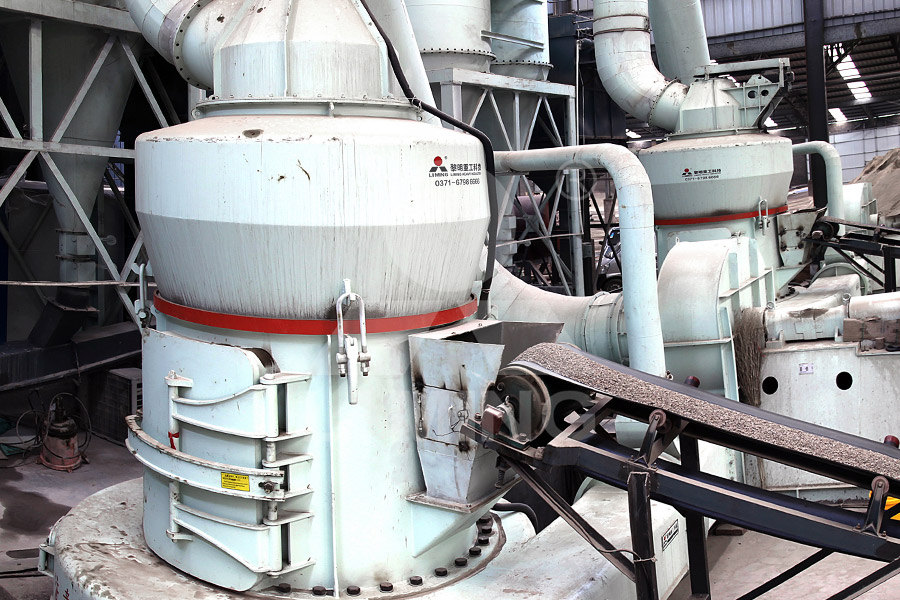

There are so many types of cement mills that can be selected for slag grinding plants Vertical mills are generally used for grinding slag powder A vertical cement mill is also called a vertical slag mill It has the advantages of high 2023年1月10日 Project capacity: 80,000 tons/year Processing material: slag Finished product size: 150200 mesh D90 Equipment configuration: LM vertical roller mill Treatment process: Slag Vertical Roller MillIn the last two decades, the number of installations for grinding cement or blastfurnace slag has increased remarkably Vertical roller mills have been used successfully for the combinedGrinding Process Optimization Featuring Case Studies and 2014年2月19日 Equipment for slag valorisation such as BF slag vertical mills, horizontal rolling mills and rod mills for steel slag crashing and grinding before final magnetic dressing, can be Current Development of Slag Valorisation in China

.jpg)

The utilization of vertical roller mills in mineral slag processing

Vertical roller mills are a key component in the modern mineral slag processing industry Their ability to efficiently grind slag into a fine powder, combined with their energysaving capabilities 2023年6月6日 Slag vertical mill selection requires rigorous numerical analysis, equipment price, scale of slag vertical mill manufacturer and aftersales capabilities are all factors that need to be considered As a slag vertical mill manufacturer with nearly 30 years of production experience, Guilin Hongcheng has rich experience in slag vertical mill parison and Analysis of Slag Vertical Mill Selection2023年1月10日 Slag Vertical Roller Mill Author: SBM Recently, the installation and commissioning of the production line with an annual output of 80,000 tons of slag powder built by SBM has been completed!Slag Vertical Roller Mill2023年12月4日 Delve into the world of Vertical Boring Mills with our comprehensive guide Discover their capabilities, applications, and benefits for machine shops! Request your quote today 9186220018Vertical Boring Mills: A Comprehensive Guide

(PDF) Drives for large vertical roller mills ResearchGate

PDF On Jan 1, 2017, J Harder published Drives for large vertical roller mills Find, read and cite all the research you need on ResearchGate2020年3月13日 600tpd Rotary Kiln Project In Shandong; Why choose cement vertical mill? There are two questions need to be clear before learning why choose cement vertical mill, The cement vertical mill has the functions of automatic slag discharge and sand discharge, Why Choose Cement Vertical Mill?The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2006 Slag Grinding With MPS Vertical Roller MillsThese mills are designed to handle the unique characteristics of slag, which can be challenging to process with traditional grinding equipment 2 How Vertical Roller Mills Work in Slag Processing Vertical roller mills operate based on the principle of compression and attrition The slag is fed into the mill's grinding chamber, where it is The utilization of vertical roller mills in mineral slag processing

.jpg)

SikaGrind® for vertical roller mills

slag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsFirst MVR mill for cement grinding 1994 More power for MPS mills by introducing the Bseries 2007 First vertical mill with MultiDrive® 2016 Biggest cement mill in the world in operation 2017 ready2grind – World’s fi rst modular system with a vertical cement millPASSION FOR GRINDINGAccording to the statistics of the association network, for the moment there are over 90,000,000 tons steel slag being produced in China every year But in 2013, the use ratio of steel slag is less than 25% CHAENG steel slag vertical mill uses many external circulation and effectively removes iron in the external circulation, Steel Slag Vertical MillThe document discusses vertical roller mills for grinding cement clinker and granulated blast furnace slag It provides a brief history of Loesche's role in developing this technology from the 1930s to present Key points include 143 LOESCHE Mills For Cement and Granulated Blast

.jpg)

Steel Slag Vertical Mill CHAENG

The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder +79; But choosing ball mill, there are at least six sets of For grinding of slag or slag cement in a vertical roller mill, grinding aid is generally not required The equipment footprint for a VRM is more compact than a ball mill; there is only a single foundation for the mill and one for the mill fan Cement grinding Vertical roller mills VS ball millsnumber of mills increased rapidly in the medieval period, probably doubling between 1086 and 1300 (though by this period some would have been windmills) After this the number of grain mills declined slowly as mills took on industrial functions, mainly fulling which was concentrated in the west and north of England and absent from much of the eastMills Historic England2012年3月1日 Vertical roller mills are the mills traditionally used for processing granulated blastfurnace slag and for grinding composite cements From the energy aspect they are superior to grinding plant Operating experience with a vertical roller mill for grinding

.jpg)

Slag grinding with the Vertical Roller Mill from China

Granulated blast furnace slag has been used as an component of blast furnace cement for many years The replacement of a certain clinker portion by blast furnace slag saves raw materials and thermal energy for pyroprocessing Granulated blast furnace slag, a byproduct of pig iron production, has been used as an important component of blast furnace cement for many slag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller mills2007年2月1日 But nowhere in the world have so many roller mills for granulated blast furnace slag grinding been sold as in China during the last 6 years First Polysius slag roller mill in China The first Polysius roller mill for slag grinding in China is in operation since 2002 in Anshan in the province of LiaoningSlag grinding with the Polysius Roller Mill in China2008年3月3日 After the slag is ground, typically in a vertical mill, the finished material generally known as GGBFS must be raised to silo storage before blending or direct dispatch The handling characteristics of the ground slag are very similar to that of finished cement and in this situation Aumund is able to use the BWGtype belt bucket elevatorsEfficient and reliable handling of GBFS and GGBFS at Global Slag

.jpg)

3 Necessary Cement Milling Comparison Ball Mill, Vertical Roller Mill

2020年11月5日 We compare 3 cement milling and cement mill processes, including cement ball mill, vertical roller mill, and rod mill Find your answer here! Skip to 6000tpd Cement Production Line Project In Shandong; compared with the cement ball mill, there are also some defects such as long process flow, many links, large plant floor Milling machines can machine materials such as metal, plastic, or wood Mills use cutting tools including end mills, face mills, and drills They can feature highquality cast iron construction, variable speed capability, power feeds, and milling cutters that move along the X, Y, and Z axes15 Different Types of Milling Machines The Engineering Choice2023年12月19日 Both machines can face and slot, but the vertical mill is more adept at prototyping, custom work, and engraving 5 There are two vertical milling machines: knee mills (also known as Bridgeporttype or turret milling Vertical Milling Machines vs Horizontal: Differences A Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for precision parts, there’s a Haas to do the workVertical Mills VMC Haas CNC Machines Haas

.jpg)

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single mill2016年9月1日 In vertical roller mills there are several factors that influence the performance of the grinding process [22] which are moisture content (mc), grinding table rotation speed (s), load pressure (P Operational parameters affecting the vertical roller mill 2023年1月9日 There are also many kinds of stainless steel materials, which need to be confirmed by the owner 2 The material of the grinding barrel rotor: In terms of the process of the sand mill, there are mainly two types, one is a disctype grinding disc, and the second is a pintype grinding barrel and a pintype rotorHow to choose the right vertical sand mill horizontal sand mill?Industrial Vertical Stirred Mills Screw Liner Wear Profile Compared to Discrete Element Method Simulations Priscila M Esteves 1, *, Douglas B Mazzinghy 1 , Roberto Galéry 1 and Luís C R Industrial Vertical Stirred Mills Screw Liner Wear Profile

Vertical raw mill Cement Plant

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industries2001年8月13日 Although vertical integration of steel mills is not necessarily a trend, there is definitely a move toward greater involvement in scrap collection and monitoring, according to John Jacobson, president of Jacobson Associates, Rochester, NYVertical Integration At Mills Recycling TodayThe slag pot itself has a characteristic: the contour of the shape is relatively large, and the entire wall has a certain thickness, and there are many plateshaped vertical ribs distributed around it, which will directly form many hot nodes which are partially dispersed and are not conducive to the feeding It will produce partial shrinkage or shrinkage holes and cracks directly in the T Design and processing of slag pot process2023年6月6日 Slag vertical mill selection requires rigorous numerical analysis, equipment price, scale of slag vertical mill manufacturer and aftersales capabilities are all factors that need to be considered As a slag vertical mill manufacturer with nearly 30 years of production experience, Guilin Hongcheng has rich experience in slag vertical mill parison and Analysis of Slag Vertical Mill Selection

Slag Vertical Roller Mill

2023年1月10日 Slag Vertical Roller Mill Author: SBM Recently, the installation and commissioning of the production line with an annual output of 80,000 tons of slag powder built by SBM has been completed!2023年12月4日 Delve into the world of Vertical Boring Mills with our comprehensive guide Discover their capabilities, applications, and benefits for machine shops! Request your quote today 9186220018Vertical Boring Mills: A Comprehensive GuidePDF On Jan 1, 2017, J Harder published Drives for large vertical roller mills Find, read and cite all the research you need on ResearchGate(PDF) Drives for large vertical roller mills ResearchGate2020年3月13日 600tpd Rotary Kiln Project In Shandong; Why choose cement vertical mill? There are two questions need to be clear before learning why choose cement vertical mill, The cement vertical mill has the functions of automatic slag discharge and sand discharge, Why Choose Cement Vertical Mill?

.jpg)

2006 Slag Grinding With MPS Vertical Roller Mills

The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to These mills are designed to handle the unique characteristics of slag, which can be challenging to process with traditional grinding equipment 2 How Vertical Roller Mills Work in Slag Processing Vertical roller mills operate based on the principle of compression and attrition The slag is fed into the mill's grinding chamber, where it is The utilization of vertical roller mills in mineral slag processingslag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller millsFirst MVR mill for cement grinding 1994 More power for MPS mills by introducing the Bseries 2007 First vertical mill with MultiDrive® 2016 Biggest cement mill in the world in operation 2017 ready2grind – World’s fi rst modular system with a vertical cement millPASSION FOR GRINDING

.jpg)

Steel Slag Vertical Mill

According to the statistics of the association network, for the moment there are over 90,000,000 tons steel slag being produced in China every year But in 2013, the use ratio of steel slag is less than 25% CHAENG steel slag vertical mill uses many external circulation and effectively removes iron in the external circulation,