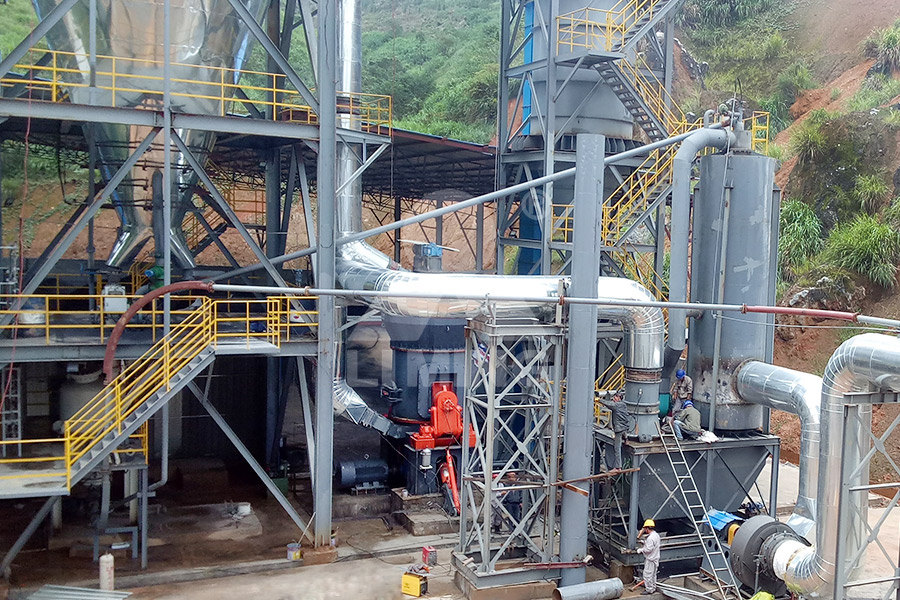

Vertical grinding ore mill PF

.jpg)

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mills are traditionally airswept mills A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table The material to be ground is fed into 2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are VRM's are state(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE Vertical stirred milling is a wellrecognized technology for the secondary, regrind and fine grinding applications and are increasingly replacing coarser ball mill applications in secondary and RECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL 2014年10月20日 PDF At the regrind or secondary grinding stages of metal ores, It is important to note here that the ore that feeds the Vertical Mill has a higher WI than the ore that feeds the ball mill(PDF) Regrind of metallic ores with vertical mills: An

Vertical Roller Mills used for the comminution of mineral ores

Different grinding modes can be realized with the MVR pilot mill: ^straight grinding where one finished product at a certain grain size is generated When using the pilot plant in ^desliming or ^selective grinding mode, a special classifier with grit extraction is used as shown in Figure 32015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plantore grades and rising energy costs, ensuring that a plant has the lowest total cost of ownership is vital Comminution of ore is one of world’s most energy Introduction of Metso’s Vertimill® VTM1500 vertical grinding mill at Miaogou Iron Mine to achieve the goal of the technologicalMetso Vertimillsvertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

.jpg)

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 View PDF; Download full issue; References (10) Cited by (21) International Journal of Mineral Processing Volume 136, 10 March 2015, Pages 3236 Copper ore grinding in a mobile vertical roller mill pilot plant Author links open Highlights • Pilot scale vertical roller mill grinding tests were performed for 2020年8月12日 PDF This study shows explored the influence of the parameter settings of a vertical roller mill on grinding Jorgensen 2005;Wang et al 2009, Ghalandari et al 2021), coal (Tontu 2020 (PDF) An investigation of performance characteristics and The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) Hungary, on a technology with Pfeiffer’s 2800 C vertical roller grinding mill The B breakage matrices were simply determined by the wellknown BroadbentCalcottModeling and simulation of vertical roller mill using population 2014年11月1日 The application of vertical mills in regrind circuits is consolidated This type of mill is now attracting interest in primary grinding applications, due to its higher efficiency when compared to (PDF) Vertical mill simulation applied to iron ores ResearchGate

.jpg)

(PDF) Regrind of metallic ores with Vertical Mills Academia

The specific energy consumption measured in the Vertical Mill was 97 kWh/t, while in the ball mill it was 112 kWh/t It is important to note here that the ore that feeds the Vertical Mill has a higher WI than the ore that feeds the ball mill The Vertical Mill uses a magnetic liner and the maintenance crew did not report any significant problems2015年3月15日 PDF Vertical Agitated Media Mill modeling has become variables on the apparent breakage rates and breakage distribution function of a batch gravityinduced stirred mill grinding copper ore(PDF) Vertical Agitated Media Mill scaleup and VTM1500 vertical grinding mill Challenge Replacing the original tertiary ball mills with Metso’s Vertimill VTM1500 vertical grinding mill Solution Introduction of Metso’s Vertimill® VTM1500 vertical grinding mill at Miaogou Iron Mine to achieve Stirred mills Metso2019年8月1日 PDF New deposits are the study ore grinding performance of the vertical roller mill was by dry grinding in Loesche vertical roller mill or by wet grinding in a rod mill are compared and (PDF) INVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE

.jpg)

RECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL

Figure 3: Relationship between feed size (F80) and Bond efficiency factor (Huang et al, 2019) VERTICAL POWER MILL (VPM) – PRINCIPLE OF OPERATION Declining ore grades and more complex ore bodies, as well as waste management and global net zero initiatives, lead to a clear trend for high tonnage yet energy efficient grindingUp to 128TPH(ore mill), up to 50TPH (coal mill) Chat Online LM Vertical Grinding Mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, PF Impact Crusher CI5X Impact Crusher HGT Gyratory Crusher GRINDING MILL LM Vertical Grinding MillLM Vertical Grinding Mill SMMVIK Machinery2015年3月15日 DOI: 101016/JMINENG201407021 Corpus ID: ; Research of iron ore grinding in a verticalrollermill @article{Reichert2015ResearchOI, title={Research of iron ore grinding in a verticalrollermill}, author={Mathis Reichert and Carsten Gerold and Andreas Fredriksson and G Adolfsson and Holger Lieberwirth}, journal={Minerals Engineering}, Research of iron ore grinding in a verticalrollermillDOI: 101016/S10036326(13)628824 Corpus ID: ; Ultra fine grinding of silver plant tailings of refractory ore using vertical stirred media mill @article{Celep2013UltraFG, title={Ultra fine grinding of silver plant tailings of refractory ore using vertical stirred media mill}, author={Oktay Celep and Ersin Yener Yazici}, journal={Transactions of Nonferrous Metals [PDF] Ultra fine grinding of silver plant tailings of refractory ore

EIRICH TowerMill Vertical agitated media mill

the mill grinding chamber, in which the vertical agitator screw is located, together with a charge of grinding media and grinding material in slurry form Highgrowth markets in copper, ironore, gold, leadzinc ores, mineral sands and rareearth metals drive increasing demand for fine grinding to maximize recovery2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on the energy Analysis and Optimization of Grinding Performance of Vertical 2013年11月1日 Ultrafine grinding of the plant tailings of a refractory silver ore was studied using a laboratory type vertical stirred media mill Preliminary tests have confirmed that ultrafine grinding Ultrafine Grinding of Silver Plant Tailings of a Refractory Ore Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore Mills for minerals and ores Loesche

(PDF) Operational parameters affecting the vertical roller mill

Grinding test results for zinc ore showed that it is possible to decrease the total grinding energy consumption from 2011 to 1140 kW h/t by using vertical roller mill instead of AG/SAGball mill circuit (van Drunick et al, 2010)grinding process with a vertical roller mill is installed ln some cases it was even possible to use a coarser product in t1otation achicving the same grade like from finer feed from conventional mill systems However the rcsults have shown moreovcr that each kind ore needs to bc tested individually in line withU Schaefer LOESCHE VERTICAL ROLLER MILLS FOR MINERAL 2018年4月16日 Request PDF Comparing Vertical Roller Mill Performance on Two Different Precious Metal Ores The vertical roller mill (VRM) is a comminution device in which crushing, grinding and Comparing Vertical Roller Mill Performance on Twothe mill grinding chamber, in which the vertical agitator screw is located, together with a charge of grinding media and grinding material in slurry form Highgrowth markets in copper, ironore, gold, leadzinc ores, mineral sands and rareearth metals drive increasing demand for fine grinding to maximize recoveryEIRICH TowerMill Vertical agitated media mill

Understanding the SAG Mill in Copper Ore Mining Process

The Tower Mill is another type of grinding mill used in the mining industry This vertical mill consists of a cylindrical chamber filled with grinding media, which are stirred by a shaft that moves vertically up and down Tower Mills were developed to overcome some of the limitations of both ball mills and SAG millsSBM Ore Ultrafine Grinding Mill Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 120 T/H Limestone Ultrafine Vertical Grinding Mill – Case in Mali Material: limestone Fineness: 500mesh Capacity: 12 t/h MO RE DETAILS Quartz SBM Ore Ultrafine Grinding MillThe mill itself consists of a rotating disk with 4 grinding pins at its periphery and an impeller wheel classifier integrated into the top section of the mill chamber The diameter of the grinding disk is 200 mm and the one of the classifier is 100 mm Both parts rotate with a (PDF) Grinding in an air classifier mill AcademiaFactors Affecting Grinding Mill Performance: 1 Grindability: The grindability of the ore affects the efficiency of the grinding mill Harder ores require more energy and longer grinding times, which can impact the mill's performance and operational costs 2Understanding the operation of grinding mills in the mining and

.jpg)

Comparing ball and vertical mills performance: An industrial case study

concentrator offers an interesting opportunity: a vertical mill operating in parallel with two ball mills During almost two years of operation, k = grinding parameter, depended on the ore characteristics and on the circuit conditions The k parameter (Donda Rosa, 2013) was used to evaluate the vertical mills performance, when2014年10月20日 PDF At the regrind or secondary grinding stages of metal ores, It is important to note here that the ore that feeds the Vertical Mill has a higher WI than the ore that feeds the ball mill(PDF) Regrind of metallic ores with vertical mills: An Different grinding modes can be realized with the MVR pilot mill: ^straight grinding where one finished product at a certain grain size is generated When using the pilot plant in ^desliming or ^selective grinding mode, a special classifier with grit extraction is used as shown in Figure 3Vertical Roller Mills used for the comminution of mineral ores2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant

Metso Vertimills

ore grades and rising energy costs, ensuring that a plant has the lowest total cost of ownership is vital Comminution of ore is one of world’s most energy Introduction of Metso’s Vertimill® VTM1500 vertical grinding mill at Miaogou Iron Mine to achieve the goal of the technologicalvertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS2015年3月10日 View PDF; Download full issue; References (10) Cited by (21) International Journal of Mineral Processing Volume 136, 10 March 2015, Pages 3236 Copper ore grinding in a mobile vertical roller mill pilot plant Author links open Highlights • Pilot scale vertical roller mill grinding tests were performed for Copper ore grinding in a mobile vertical roller mill pilot plant2020年8月12日 PDF This study shows explored the influence of the parameter settings of a vertical roller mill on grinding Jorgensen 2005;Wang et al 2009, Ghalandari et al 2021), coal (Tontu 2020 (PDF) An investigation of performance characteristics and

.jpg)

Modeling and simulation of vertical roller mill using population

The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) Hungary, on a technology with Pfeiffer’s 2800 C vertical roller grinding mill The B breakage matrices were simply determined by the wellknown BroadbentCalcott2014年11月1日 The application of vertical mills in regrind circuits is consolidated This type of mill is now attracting interest in primary grinding applications, due to its higher efficiency when compared to (PDF) Vertical mill simulation applied to iron ores ResearchGateThe specific energy consumption measured in the Vertical Mill was 97 kWh/t, while in the ball mill it was 112 kWh/t It is important to note here that the ore that feeds the Vertical Mill has a higher WI than the ore that feeds the ball mill The Vertical Mill uses a magnetic liner and the maintenance crew did not report any significant problems(PDF) Regrind of metallic ores with Vertical Mills Academia