Cement vertical mill ash meter

.jpg)

Vertical roller mills FLSmidth Cement

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding material It VRM In Cement Plant Maximize Energy Saving CNBMSINOMAFor decades, vertical roller mills have been in use in the cement industry for grinding of raw material and coal Since the 1980s vertical roller mills have been also used for combined or C Woywadt, Gebr Pfeiffer SE, Kaiserslautern, GermanyPada Vertical Cement Mill terjadi empat proses yang berlangsung secara simultan Keempat proses tersebut yaitu penggilingan, pengeringan, transport, dan separasi Proses penggilingan, pengeringan EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill)

.jpg)

Vertical Mill In Cement Plant Cement Vertical Mill

Vertical mill merges fine crushing, drying, grinding and powder selecting into a single, which simplifies the production process It has the advantages of high grinding efficiency, low power consumption, large feed particle size, easy 1999年4月18日 A class of cements based on a new cementitious phase alinite has been produced by clinkering at 1150°C, the steel plant wastes such as fly ash, limestone fines, mill scale, magnesite dust and (PDF) EVALUASI KINERJA VERTICAL ROLLER MILL Furthermore, VRMs can use waste materials such as blast furnace slag and fly ash as raw materials, reducing the need for virgin materials and landfill space Application of Vertical Roller Mill in Cement Industry Vertical roller mill (VRM) technology has become an integral part of the cement industry, Application of Vertical Roller Mill in Cement ProductionVertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCement grinding Vertical roller mills VS ball mills

.jpg)

Vertical Cement Mill

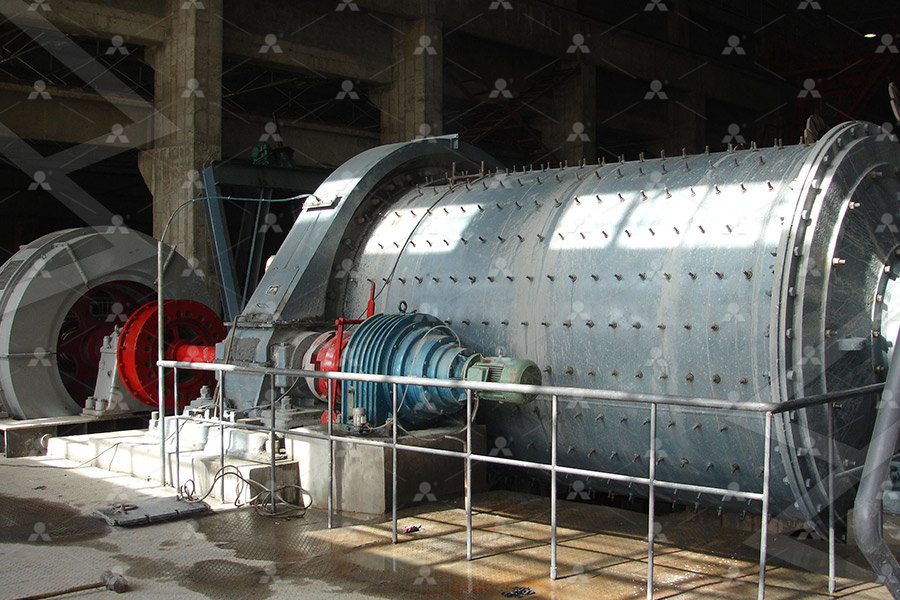

The vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind 2022年10月3日 Calculation of thermal efficiency in a vertical cement mill is carried out in two stages, [Show full abstract] bahan korektif seperti pozzolan,gypsum, fly ash, dll pada tahap akhir (finish mill)(PDF) EFISIENSI THERMAL ALAT VERTICAL CEMENT MILL PABRIK 2020年3月13日 In recent years, with the need for largescaled cement grinding and energysaving, cement vertical mill becomes the mainstream of cement millAs we all know, there are some kinds of cement grinding mill on the market, such as cement ball mill, cement vertical mill, cement roller press, etcWhy choose cement vertical mill?Why Choose Cement Vertical Mill?31 – VERTICAL MILL COMPONENTS Image 1 shows a vertical mill and its components: Grinding plate Rollers pressing the material on the grinding plate Pressure system of the grinding rollers Hot gas flow for drying the raw materials and cement temperature control Dynamic third generation separatorTechnical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS

Cement Mill Cement Ball Mill Vertical Cement Mill Factory

The cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other highquality cement grinding machines for you! Skip to Coal Mill Apply for coal, fly ash, coal gangue, etc Raymond Mill apply for finegrinding of limestone, calcium carbonate, barite, calcite Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and Vertical roller mills FLSmidth Cement2021年1月29日 By initiating a CL for an industrial cement vertical roller mill (VRM), this study conducted a novel strategy to explore relationships between VRM monitored operational variables and their Increase productivity of vertical roller mill using seven menunjukkan bahwa Vertical Cement Mill Pabrik II PT Semen Baturaja (Persero) Tbk masih menguntungkan untuk digunakan karena tidak banyak energi yang terbuang saat alat beroperasiMenghitung Efisiensi Alat Vertical Cement Mill Motor Di Pabrik II

OK™ Raw and Cement Mill

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetime2022年1月10日 Vertical Cement Mill is the main tool used in the final process of making cement at PT Semen Baturaja (Persero) Tbk Vertical Cement Mill is used to mix and grind clinker and corrective materialsAnalisa Kinerja Alat Vertical Cement Mill di Pabrik II PT Semen The world’s largest vertical roller mill has Grinding Table Diameter of 808 meter and Roller Diameter of 264 meter The VRM has been successfully commissioned at Shah Cement’s manufacturing facility and will produce 60 Lac tons of cement per year at a rate of 15 thousand tons of cement every dayShah Cement Industries Limited A concern of Abul Khair GroupVertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical raw mill Cement Plant

.jpg)

PERANCANGAN FASILITAS JEMBATAN UNTUK MEMINDAHKAN DRIVE MOTOR CEMENT MILL

pemindahan main drive motor cement mill dapat dilakukan dengan cepat, dan aman Kata kunci: main drive motor, Jembatan, Hbeam, Solidworks Abstract Cement mill is an equipment that serves to grind cement raw materials The type of cement mill used by PT Holcim Indonesia Tuban plant is Vertical Roller mill product from LoescheVertical Cement Mill digunakan untuk mencampurkan dan menghaluskan clinker dan bahan – bahan korektif Selain itu, alat ini juga digunakan sebagai pengering dengan memanfaatkan udara panas dariANALISA KINERJA ALAT VERTICAL CEMENT MILL DI PABRIK II PTRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by Raw mill Cement PlantAGICO provides the cement ball mill, rod mill, cement vertical mill, Raymond mill, air swept coal mill, etc Skip to content Blog Contact About Cases Factory CONTACT US info@cementplantequipment CALL US +86 Grinding Mill Grinding Equipment Cement Mill

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single mill2019年10月18日 How to select a costeffective cement mill? AGICO Cement supplies highquality cement ball mill, vertical roller mill, cement roller press, any need? Skip to content +86 s about How To Select Cement Mill? Cement Ball Mill, Mill Feeders: Feeders will be directly installed under hoppers with rod gate in between The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill Feeders for mills meter feed rates and also tantalize tons fed For cement mill feeding, table feeders, belt feeders, and weigh feeders have been usedCement Mill Feeding Cement Plant OptimizationClosed circuit system mainly composed of the cement vertical mill Roller press and ball mill pregrinding system Slag and steel slag grinding system Coal which can effectively carry the fine particles in the materials that slide into the ash hopper into the classification surface and improve the classification efficiency by 510% Cement Mill Separator High Efficiency Cement Separator

TRM SERIES CEMENT VERTICAL ROLLER MILL TRM SERIES CEMENT VERTICAL

TRM SERIES CEMENT VERTICAL ROLLER MILL TRM SERIES fly ash when producing PC 325 cement, the fly ash will be fed from the casing of separator in order to avoid excessive grinding of material and improve the work efficiency The flow sheet is as the following:Ball Mill The fly ash ball mill is the special equipment for fly ash grinding, which is designed and developed by our company after years of research and practice It is the most ideal equipment for further processing of fly ash The ball mill adopts the particular structure and grinding mediaFly Ash Processing Plant Cement Equipment ManufacturingA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote MachineryTable 3 Power Consumption Of Roller Press Grinding System Overall, we can conclude the three tables: After the longterm operation, although unit raw material grinding power consumption of the cement roller press grinding system is still low, the indexes of the vertical roller mill grinding system are very close to it, among which the output power of the vertical mill and the roller Comparison Of Vertical Roller Mill And Roller Press Mill

Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw Mill

AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the Pada Vertical Cement Mill terjadi empat proses yang berlangsung secara simultan Keempat proses tersebut yaitu penggilingan, pengeringan, transport, dan separasi Proses penggilingan, pengeringan EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill)Vertical mill merges fine crushing, drying, grinding and powder selecting into a single, which simplifies the production process It has the advantages of high grinding efficiency, low power consumption, large feed particle size, easy Vertical Mill In Cement Plant Cement Vertical Mill1999年4月18日 A class of cements based on a new cementitious phase alinite has been produced by clinkering at 1150°C, the steel plant wastes such as fly ash, limestone fines, mill scale, magnesite dust and (PDF) EVALUASI KINERJA VERTICAL ROLLER MILL

Application of Vertical Roller Mill in Cement Production

Furthermore, VRMs can use waste materials such as blast furnace slag and fly ash as raw materials, reducing the need for virgin materials and landfill space Application of Vertical Roller Mill in Cement Industry Vertical roller mill (VRM) technology has become an integral part of the cement industry, Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCement grinding Vertical roller mills VS ball millsThe vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind Vertical Cement Mill2022年10月3日 Calculation of thermal efficiency in a vertical cement mill is carried out in two stages, [Show full abstract] bahan korektif seperti pozzolan,gypsum, fly ash, dll pada tahap akhir (finish mill)(PDF) EFISIENSI THERMAL ALAT VERTICAL CEMENT MILL PABRIK

Why Choose Cement Vertical Mill?

2020年3月13日 In recent years, with the need for largescaled cement grinding and energysaving, cement vertical mill becomes the mainstream of cement millAs we all know, there are some kinds of cement grinding mill on the market, such as cement ball mill, cement vertical mill, cement roller press, etcWhy choose cement vertical mill?31 – VERTICAL MILL COMPONENTS Image 1 shows a vertical mill and its components: Grinding plate Rollers pressing the material on the grinding plate Pressure system of the grinding rollers Hot gas flow for drying the raw materials and cement temperature control Dynamic third generation separatorTechnical Notebook CEMENT ADDITIVES FOR VERTICAL MILLSThe cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other highquality cement grinding machines for you! Skip to Coal Mill Apply for coal, fly ash, coal gangue, etc Raymond Mill apply for finegrinding of limestone, calcium carbonate, barite, calcite Cement Mill Cement Ball Mill Vertical Cement Mill Factory