Supply of quicklime ore powder processing equipment

.jpg)

China Quicklime Grinder Manufacturer, Supplier JINGHUA

Enhance your quicklime processing with our Quicklime Grinder designed and manufactured by Weifang Jinghua Powder Engineering Equipment Co, Ltd This highperformance grinder is specifically engineered for efficiently grinding quicklime to the desired particle size for various Our company specializes in providing topoftheline pulverizing equipment for various applications, including quicklime processing, Our quicklime pulverizer is designed to efficiently China Quicklime Pulverizer Manufacturer, Supplier JINGHUAChina Quick Lime Plant Equipment wholesale Select 2024 high quality Quick Lime Plant Equipment products in best price from certified Chinese Machine Equipment Control Quick Lime Plant Equipment MadeinChinaThis equipment is a new generation of calcium oxide (quicklime) digestion equipment based on more than ten years of practical experience in lime digestion and summarizing the pulse bag Quick Lime Slaker Guilin Mining Machinery Co, Ltd

srlime

Our reputation as a top leading supplier extends beyond the national market, as we also export our highquality products globally to countries such as Vietnam, Malaysia, Pakistan, India, Quicklime or Calcium Oxide (CaO), is an alkaline and crystalline solid utilized in several environmental and industrial applications Graymont can supply various types of quicklime in Quicklime GraymontHigh calcium quicklime, or lime, is one of the most effective alkaline materials commonly used to neutralize acidic compounds, adjust pH, remove impurities, disinfect, stabilize sludge, remove High Calcium Quicklime CarmeuseGraymont can supply both crushed and pebble high calcium quicklime from various sites that is suitable for either subsequent further processing and slaking or direct slaking Some of the High Calcium Quicklime Graymont

.jpg)

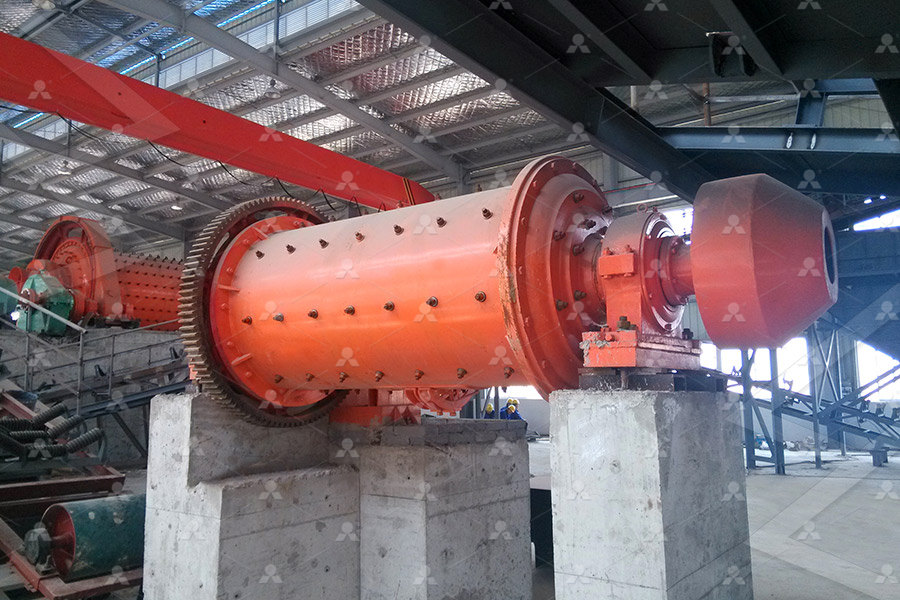

White quicklime powder mill equipment

Find the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale white quicklime powder mill equipment model and mills for any mining challenge – CHEMICAL HYDRATED LIME POWDER 50 T (Eskom Spec) Chemical hydrated lime, also known as calcium hydroxide, is a highly reactive and versatile inorganic compound widely used in various industrial and construction applicationsIt is produced by the hydration of quicklime (calcium oxide) with water, resulting in the formation of a white powder with a strong alkaline pHCHEMICAL HYDRATED LIME POWDER 50 T NKOKHI GROUPHigh calcium quicklime (CaO) is produced when limestone, or calcium carbonate (CaCO 3), is heated in a kiln through the process of calcination CaCo 3 + heat > Cao = CO 2 After limestone with high calcium content is sourced from our High Calcium Quicklime Carmeuse2022年12月29日 The roles of iron ore, fuel, fluxes, and moisture in sintering granulation are also analyzed, and finally advanced granulation equipment and processes for industrial production, as well as their (PDF) Iron Ore Granulation for Sinter Production:

.jpg)

Lime Slaking Systems Quicklime Slakers Lime Systems

Lime slaking processes Quicklime, also known as calcium oxide (CaO) or simply lime, is produced by heating limestone or calcium carbonate in big furnaces During this heating process, CO2 is released from the stone, resulting in the formation of CaO along with some other small mineral components2024年6月24日 Imports play a significant role in ensuring a steady supply of Quicklime to meet various industrial needs Here’s why imports matter: Meeting Demand: Imports help bridge the gap between local production and market demand In cases where domestic supply may fall short, importing Quicklime becomes essential to keep operations running smoothlyYour Guide to Sourcing HighQuality Quicklime in Egypt Zme2023年7月4日 A briquetting machine, also called a briquette press machine or briquettemaking machine, is a device that converts powdered or granular materials into larger, more convenient shapes called briquettes According to materials, there are 5 most popular briquette machines at present: charcoal briquette machine, coal briquette machine, metal powder briquette machine, 5 Types of Briquette Machines (With Budget Analysis)6 天之前 Copper ore generally adopts flotation production line for beneficiation processing, among which copper ore flotation machine is the key equipment The copper ore flotation machine is designed through multistage separation tanks so that the entire flotation process is gradually completed, forming a cascade optimizationCopper Ore Processing Plants, Flow And Equipment

Lime/quicklime for metallurgy – how producing and briquetting

2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is According to the quicklime mesh and output, the following suggestions are given for the selection of quicklime powder grinding mills for reference only Quicklime Powder 1 Raymond mill is used for quicklime powder making It is recommended to use Raymond mill for the processing of quicklime with an output of 1 to 9 tons and a mesh of 80 to How to choose quicklime powder grinding mill?This is where the real game begins, although the early levels still somewhat act as tutorials To start with, take a look around this floor you will see two new machines you can scan Assembler Ingredients: 2x Iron Frame 2x Inserter and Crank Generator Ingredients: 4x Electrical Components 8x Copper Components s Not only will Assembler Ingredients: 2x Iron FrameTechtonica Database Gameguide2022年7月15日 Wet granulation plays an important role in the processing of fine ore powder Water content is a critical process parameter that determines the granule properties during wet granulationDetermining Optimum Water Content for Iron Ore

.jpg)

Advancements in ore powder production process equipment:

The continuous advancements in ore powder production process equipment are transforming the mineral processing industry With the ability to produce highquality powders efficiently and sustainably, these technologies are not only meeting the demands of various applications but also contributing to the environmental stewardship of the industryWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS The six main steps of iron ore processing Multotec2024年4月16日 Store your quicklime After you’ve let your quicklime cool, you need to prepare to store it Storing it properly is extremely important as quicklime is a potentially dangerous substance There are a number of things you should consider when storing quicklime Store it in a dry heavyplastic or metal container Seal your container wellHow to Make Quicklime: 10 Steps (with Pictures) wikiHowF: Fine ore powder, C P: Coarse ore powder (porous), C LP: Coarse ore powder (less porous) Table 2 Specific surface areas of ores Sample Air permeation method [cm2/g] BET [m2/g] F 3 682 103 C P* 4 982 266 C LP* 3 405 84 *Powders were milled to less than 100 μm Fig 1 Particle size distributions: (a) coarse ore particles and (b) fine ore Optimum Water Content Estimation for Wet Granulation of Iron Ore

.jpg)

Powder Processing Equipment British Rema

British Rema offer a comprehensive range of powder processing equipment systems including classifiers, mills, mixers rotary dryers Discover more Call us on:+44 (0) We supply a wide range of powder processing equipment suitable for any scale, from RD through to For big consumptions of powder, quicklime will be the best powder to choose as the density (1g / cm³) is twice the density of the hydrated lime (0,5 g / cm³) which reduces the storage and transportation costs On the other hand, quicklime requires a lime slaker due to its hydrophobic reaction with waterWhat are examples of some uses for quicklime? Hebei Yayang Processing Equipment Blenders Mixers, Mills, Classifiers, Feeders, etc Our oldest area of expertise, the processing umbrella includes equipment needed to mix, separate, and alter products: milling, blending/mixing, particle size reduction, filtration, sifting, dust collection, process controls, and volumetric and gravimetric weighers and feedersIndustrial Process Equipment, Systems, Service ABM Equipment2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine Powder

Decarbonizing lithiumion battery primary raw materials supply

2024年11月20日 This heat is generated from coal 37 For nickel sulfate, a mix of natural gas, coal, and heavy fuel oil is used to supply process heat for the pyrometallurgical processing of sulfide ores and highpressure acid leaching (HPAL) of laterite ores (involving the reaction of a slurry with sulfuric acid in an autoclave at ca 255°C) 42 Overall, heat sources are typically SUPPLY Chememan Quicklime is available in various sizes ranging from lump, pebble and powder forms Our products are delivered to customers’ sites in pneumatic bulk tankers or 10 – 15 MT bulk bags STANDARDS AND CERTIFICATION Chememan Quicklime is a high Calcium Lime complying with Australian Standard AS 44891997 Test MethodsABN P PRODUCT DATA SHEET QUICKLIME PRODUCT 2012年1月27日 The main differences between hydrated lime and quicklime are their reactivity their chemical composition Hydrated lime and quicklime are both calcium compounds In its hydrated state, calcium is called calcium hydroxide, Differences between Hydrated lime and quicklimeWelcome to PPDS Founded in 2004, Powder Process Design Services Ltd has rapidly established a first class reputation in the design, manufacture and supply of powder processing solutions to serve the needs of companies in the following sectors:Powder Process Design Services Limited

.jpg)

Vertical mill: The preferred equipment for quicklime production

The vertical mill stands out as the preferred equipment for quicklime production due to its high efficiency, energy savings, environmental protection, and ease of maintenance Its advanced grinding technology and compact design make it an ideal choice for lime producers looking to enhance their operational capabilities and product quality2022年3月21日 Significant academic research and moderate commercial process innovation on rareearth element (REE) processing have been underway for decades The last several years have seen exponential growth in research due to growth in demand of REE that is threatened by supply risks and environmental obstacles The REE industry appears to be at the intersection Processing the ores of rareearth elements MRS BulletinCopper Ore Processing Plant in South Africa: Chemical Separation A copper mine in South Africa adopts the process of leaching — extraction — electrodeposition The plant's copper ore contains oxide ores such as malachite and malachite, and sulphide ores such as chalcocite and bornite Ore processing flow: 1 Crush the ores to 6 mmCopper Ore Processing Plant Fote Machinery2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments The primary objective of crushing is to reduce the ore size for subsequent processing and improve the liberation of valuable minerals from the gangue a Jaw Crushers: Jaw crushers are commonly used for primary Iron Ore Processing: From Extraction to Manufacturing

.jpg)

LIME SLAKING SYSTEMS Bulk Handling Technologies Australia

Lime Slaking Plant Design Focus Process Control With lime slaking, the two key inputs to be controlled are water and quicklime addition These ingredients must be added in the correct ratio to meet the required system production rate and also Our Team of dedicated Market Specialists can provide applications advice, as well as solutions and equipment for the transport, storage and dosing of Quicklime products Burnt Lime 40 ® Burnt Lime 40 is a white, lump calcium oxide product which is Quicklime Singleton Birch2023年1月19日 Wet granulation plays an important role in the processing of fine ore powder Water content is a critical process parameter that determines the granule properties during wet granulationOptimum Water Content Estimation for Wet Granulation of Iron Ore – CHEMICAL HYDRATED LIME POWDER 50 T (Eskom Spec) Chemical hydrated lime, also known as calcium hydroxide, is a highly reactive and versatile inorganic compound widely used in various industrial and construction applicationsIt is produced by the hydration of quicklime (calcium oxide) with water, resulting in the formation of a white powder with a strong alkaline pHCHEMICAL HYDRATED LIME POWDER 50 T NKOKHI GROUP

High Calcium Quicklime Carmeuse

High calcium quicklime (CaO) is produced when limestone, or calcium carbonate (CaCO 3), is heated in a kiln through the process of calcination CaCo 3 + heat > Cao = CO 2 After limestone with high calcium content is sourced from our 2022年12月29日 The roles of iron ore, fuel, fluxes, and moisture in sintering granulation are also analyzed, and finally advanced granulation equipment and processes for industrial production, as well as their (PDF) Iron Ore Granulation for Sinter Production: Lime slaking processes Quicklime, also known as calcium oxide (CaO) or simply lime, is produced by heating limestone or calcium carbonate in big furnaces During this heating process, CO2 is released from the stone, resulting in the formation of CaO along with some other small mineral componentsLime Slaking Systems Quicklime Slakers Lime Systems2024年6月24日 Imports play a significant role in ensuring a steady supply of Quicklime to meet various industrial needs Here’s why imports matter: Meeting Demand: Imports help bridge the gap between local production and market demand In cases where domestic supply may fall short, importing Quicklime becomes essential to keep operations running smoothlyYour Guide to Sourcing HighQuality Quicklime in Egypt Zme

5 Types of Briquette Machines (With Budget Analysis)

2023年7月4日 A briquetting machine, also called a briquette press machine or briquettemaking machine, is a device that converts powdered or granular materials into larger, more convenient shapes called briquettes According to materials, there are 5 most popular briquette machines at present: charcoal briquette machine, coal briquette machine, metal powder briquette machine, 6 天之前 Copper ore generally adopts flotation production line for beneficiation processing, among which copper ore flotation machine is the key equipment The copper ore flotation machine is designed through multistage separation tanks so that the entire flotation process is gradually completed, forming a cascade optimizationCopper Ore Processing Plants, Flow And Equipment2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is Lime/quicklime for metallurgy – how producing and briquettingAccording to the quicklime mesh and output, the following suggestions are given for the selection of quicklime powder grinding mills for reference only Quicklime Powder 1 Raymond mill is used for quicklime powder making It is recommended to use Raymond mill for the processing of quicklime with an output of 1 to 9 tons and a mesh of 80 to How to choose quicklime powder grinding mill?

.jpg)

Techtonica Database Gameguide

This is where the real game begins, although the early levels still somewhat act as tutorials To start with, take a look around this floor you will see two new machines you can scan Assembler Ingredients: 2x Iron Frame 2x Inserter and Crank Generator Ingredients: 4x Electrical Components 8x Copper Components s Not only will Assembler Ingredients: 2x Iron Frame