Jinyang quicklime coal plant output

.jpg)

Study on Carbon Emission Characteristics and Emission Reduction

2023年5月11日 The output of quicklime and the material and energy consumption for the production of quicklime from 2019 to 2021 are shown in Table 3 The output data in Table 3 show a steady upward trend In 2021, with effective epidemic prevention and control measures in 2022年10月1日 Quicklime reacts spontaneously with water, and its transport requires strict safety measures, given the strong exothermicity of its hydration reaction (114 MJ released per Decarbonising the lime industry: Stateoftheart ScienceDirect2023年8月22日 This is China’s most recent electricityfocused inputoutput dataset, featuring novel improvements in subelectricity identification, especially mapping six detailed coal power Chinese electricityfocused inputoutput dataset with detailed coal Download scientific diagram The material and energy consumption for the production of quicklime in 2021 from publication: Study on Carbon Emission Characteristics and Emission The material and energy consumption for the production of

New superlative lime plant with a daily capacity of 5,000 tons of

2022年12月21日 With its capacity of almost 5,000 tons of quicklime per day, the new plant will be the largest lime plant ever built on a greenfield site, surpassing even the recently completed 2022年2月1日 In this paper, we tracked the carbon footprint of coalfired power plants from 2000 to 2020 in China, considering both construction and various operating processes We linked Tracking the carbon footprint of China's coalfired power system2018年12月5日 This study uses hourly generation data from the US Environmental Protection Agency’s (EPA) Air Markets Program to determine how operations have changed at 48 large Analysis of hourly generation patterns at large coalfired units and quicklime has a absolutely high content of CaO with released large amount of heat during digestion, which can effectively increase the temperature of the material mixture In addition, in Comprehensive Technologies for Iron Ore Sintering with a Bed

Coal power in China Wikipedia

Coal power in China is electricity generated from coal in China and is distributed by the State Power Grid Corporation It is a big source of greenhouse gas emissions by China China's 2020年6月29日 CO2 intensity target from the average coal consumption target for operated coal plants is stated in the 13th FiveYear Plan for Power Development, which corresponds to the use of the CO2 fuel factor for “other bituminous coal” (ie 95 kgCO2/GJ) Related chartsAverage CO2 intensity of power generation from coal power plantsCoal Quantity Since coal has a heat value of 20,000 kJ/kg, for producing one kwhr we require (10765 / 20000) 0538 kg of coal This translates to (0538 x 100 x 1,000) 53800 kg/hr (538 T/hr) of coal for an output of 100 MW Coal Cost Basic cost of coal depends on the market conditionsHow to Calculate the Coal Quantity Used in a Power Plant2015年6月2日 Abstract Coalfired power plants emit large amounts of CO2 , which constitutes one of the largest causes of global warming Reducing CO2 emissions in the energy sector has become a top priority (PDF) COALFIRED POWER PLANTS ENERGY

.jpg)

Prediction of power output of a coalfired power plant by

2009年12月30日 Accurate modeling of thermal power plant is very useful as well as difficult Conventional simulation programs based on heat and mass balances represent plant processes with mathematical equations These are good for understanding the processes but usually complicated and at times limited with large number of parameters needed On the other hand, Quicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industry In the basic oxygen steelmaking (BOS) process, quicklime Quicklime Preparation, Properties, and Applications with FAQsPlant Bowen, the third largest coalfired power station in the United States Sources of electricity for 2016 [1] Coal electrical generation (black line), compared to other sources, 1949–2016 Coal power generation in 2011 by state Coal generated about 195% of the electricity at utilityscale facilities in the United States in 2022, down from 386% in 2014 [2] and 51% in 2001 [3]Coal power in the United States Wikipedia2021年12月6日 In Germany, for instance, the costs for redispatching (with countertrading), feedin management, and grid reserve power plants 14 (see Table 1) in 2017 (EUR 1511 million, 26 103 GWh) 15 increased by 69% compared to 2016 (EUR 894 million, 16 427 GWh), 15 mainly caused by delays in transmission grid expansion plus weak winds in 2016 16, 17 and strong Minimum loads of coal‐fired power plants and the potential

CoalFired Thermal Power Plant ScienceDirect Topics

A coalfired power plant (Fig 2) operates by burning coal to generate heat, which is then used to produce steam in a boilerThe highpressure steam drives turbines connected to generators, converting the kinetic energy into electricity Coalfired power plants have long been prominent in electricity generation due to the abundant availability of coal reserves2023年5月11日 International Atomic Energy Agency Vienna International Centre, PO Box 100 A1400 Vienna, Austria Telephone: +43 (1) 26000, Facsimile +43 (1) 26007Infographics: Nuclear Energy Compared IAEA2020年3月26日 The number of plants newly under construction each year is falling even faster, down 66% in 2019 compared to 2015, according to the latest annual status report from Global Energy Monitor Meanwhile, coal retirements are at historically unprecedented levels, with the 34GW of closures in 2019 a close third behind 2015 (37GW) and 2018 (35GW)Mapped: The world’s coal power plants in 2020 Carbon Brief2022年10月7日 Abstract This paper describes a realtime performance monitoring method based on PTC 42013 for determining instantaneous heat rates for coalfired power plants The calculation protocol uses a modified output–loss approach applied to a control volume that closely conforms to the boiler The largest energy balance term is the heat transfer rate to the steam, A RealTime Output–Loss Method for Monitoring Heat Rate for Coal

.jpg)

Current design and construction of coalfired power plant ICSC

coalfired plant construction with particular emphasis on North America, Europe, China, India, Malaysia, Thailand, South Korea and Australia Available data are tabulated on the locations of coalfired plants presently under construction and the boiler manufacturers receiving orders for each year since 2001 and for the whole period from 1993 to 2 Process description of a coalfired power plant A coalfired power plant burns coal to produce electricity In a typical coalfired plant, there are pulverisers to mill the coal to a fine powder for burning in a combustion chamber of the boiler Exergy Analysis and Efficiency Improvement of a Energy Information Administration FAQs: "As of December 3, 2018, there were 98 operating nuclear reactors at 61 nuclear power plants in the United States The R E Ginna Nuclear Power Plant in New York is the smallest nuclear power plant in the United States, and it has one reactor with an electricity generating capacity1 of 582 megawatts (MW)How much electricity does a typical nuclear power plant generate?In the APS, global output from existing unabated coal‐fired plants is reduced by nearly 2 500 terawatt‐hours from 2021 to 2030 to get on track for national climate pledges, This means an unabated coal plant produces less electricity over a certain period but remains available at times when the system needs are highest, Coal IEA International Energy Agency

FlueGas Desulphurization an overview ScienceDirect Topics

Control and Treatment of Air Emissions Shahryar Jafarinejad, in Petroleum Waste Treatment and Pollution Control, 2017 515 FlueGas Desulfurization Fluegas desulfurization (FGD) is a scrubbing technique that uses an alkaline reagent (typically a sodium or calciumbased alkaline regent) to remove SO 2 from flue gas (TriState Synfuels Company, 1982; Tilly, 1983; In quicklime project, the quicklime Zhejiang calcitelimestone ultrafine powder production line with annual output of 100,000 tons Raw material: calcite Finished powder fineness: 12501600 mesh Gansu bituminous coal grinding production line with annual output of 200,000 tons Raw material: bituminous coal Processing capacity quicklime processing plant, quicklime grinding machine, quicklime 2021年9月1日 Soft coal is also known as brown coal or lignite China produces more hard coal than any other country by a factor of about three The whopping 3,162 million metric tons of hard coal produced by China dwarfs the output of the second and thirdranked producers—the US at 932 million metric tons and India at 538 million metric tonsThe Types of Coal: Composition, Usage, and Energy ValueCoal generated 16% of electricity in the United States in 2023, [1] an amount less than that from renewable energy or nuclear power, [2] [3] and about half of that generated by natural gas plants Coal was 17% of generating capacity [4] Between 2010 and May 2019, 290 coal power plants, representing 40% of the US coal generating capacity, closedList of coalfired power stations in the United States Wikipedia

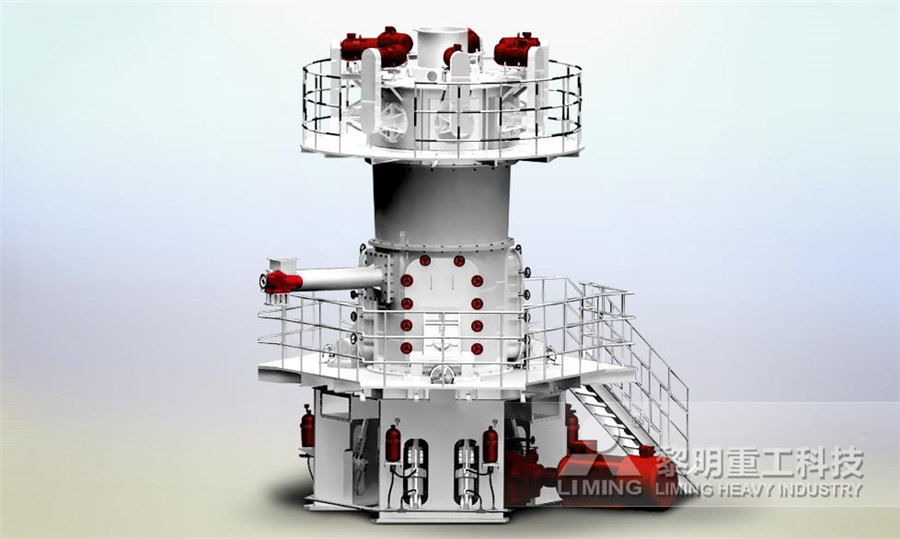

Lime Calcination Plant Solution 2001000tpd Quicklime CNBM

Lime Calcination Plant Finished products: active lime Limekiln: rotary kiln (vertical shaft kiln upon request) Capacity: 2001000t/d Limestone granularity: 2040 mm Fuel: gas, pulverized coal Get the solution now!Product: Lime Calcination Plant Capacity: 50 – 1200 T/D FUEL: Coal Gas, Natural Gas, Oil Gas and Pulverized Coal Application: Active Lime Production Line/ Quicklime Production Line/ Hydrated Lime Production Line/ Construction Industry/ Steel Industry/ Chemical Industry/ Agriculture Calcining Kiln for Lime Calcination Plant: Rotary Lime Kiln, Vertical Lime Kiln, Lime Calcination Plant with Output of 501200 T/D for SaleCyclone classification of the output to 75 microns and delivery to a local 50 cubic metres agitated storage tank for a transfer to a remote plant storage tank Quicklime Slaking Facilities 4 NEWCREST MINING LTD Lihir Island, Papua Oil, Waste oil, various coals, Pet coke or sawdust are available Cimprogetti’s development of the single COMPLETE PLANT CAPABILITY LIME SYSTEMS LTD2015年11月15日 Coal will continue to be a dominant energy source also in the next decades It was responsible for 41% of the world power generation in 2012 and is projected to be around 31% in 2040 [1]Coalfired power plants have been in continuous development for more than 100 years with considerable efforts to improve the capacity and thermal efficiencyThermal efficiency of coalfired power plants: From theoretical

.jpg)

Chinese electricityfocused inputoutput dataset with detailed coal

2023年8月22日 The electricityfocused inputoutput model is a popular approach for analysing the socioeconomic and environmental impacts of electricity decarbonisation policies; however, it cannot be built HOW ELECTRICITY IS PRODUCED AT A COALFIRED POWER STATION An overview of power generation at a modern coalfired power station INTRODUCTION stages contributes to the total 618MW output of the generator The HP turbine delivers 154,5MW (25%), the IP turbine 278,1MW (45%) and the two LP turbines 92,7MW HOW ELECTRICITY IS PRODUCED AT A COALFIRED POWER systems at coalfired electric power plants, construction, and water purification In 2006, lime was used for the following purposes: metallurgical uses (36%), environmental uses (29%), chemical and industrial uses (21%), construction uses (13%), and to Technical Support Document for the Lime Manufacturing SectorA steam power plant with a power output of 150 MW consumes coal at a rate of 60 tons/h If the heating value of the coal is 30,000 kJ/kg, determine: (a) The overall efficiency of this plant (b) The heat discarded to the cooling water (MW) 1 ton = 1000 kg 1 MW = 1000 kW Heating value is the amount of heat released when 1 kg of the fuel is burnedSolved A steam power plant with a power output of 150 MW Chegg

Environmental Performance of CoalBased Thermal Generation Plants

2024年9月3日 Mittal, M L (2010) Estimates of emissions from coal fired thermal power plants in India 39, 1–22 Google Scholar Chakraborty, N, et al (2008) Measurement of CO 2, CO, SO 2, and NO emissions from coalbased thermal power plants in India Atmospheric Environment, 42, 1073–1082 Article Google Scholar2024年9月4日 Firering Strategic Minerals plc (LON:FRG) Chief Executive Officer Yuval Cohen and Independent NonExecutive Director Vassilios Carellas caught up with DirectorsTalk for an exclusive interview to discuss the quicklime plant modifications, the importance of the coal gasification unit, existing stockpiles and laboratory, and what investors can expect in relation Firering Strategic Minerals discusses Quicklime Plant Progress Jinyang ZHENG, Yue ZHANG, Dongsheng HOU, Yinkang QIN, Weican GUO, Chuck ZHANG, Jianfeng SHI A review of nondestructive examination technology for polyethylene pipe in nuclear power plantREVIEWARTICLE Jinyang ZHENG A review of nondestructive 2020年6月29日 CO2 intensity target from the average coal consumption target for operated coal plants is stated in the 13th FiveYear Plan for Power Development, which corresponds to the use of the CO2 fuel factor for “other bituminous coal” (ie 95 kgCO2/GJ) Related chartsAverage CO2 intensity of power generation from coal power plants

How to Calculate the Coal Quantity Used in a Power Plant

Coal Quantity Since coal has a heat value of 20,000 kJ/kg, for producing one kwhr we require (10765 / 20000) 0538 kg of coal This translates to (0538 x 100 x 1,000) 53800 kg/hr (538 T/hr) of coal for an output of 100 MW Coal Cost Basic cost of coal depends on the market conditions2015年6月2日 Abstract Coalfired power plants emit large amounts of CO2 , which constitutes one of the largest causes of global warming Reducing CO2 emissions in the energy sector has become a top priority (PDF) COALFIRED POWER PLANTS ENERGY 2009年12月30日 Accurate modeling of thermal power plant is very useful as well as difficult Conventional simulation programs based on heat and mass balances represent plant processes with mathematical equations These are good for understanding the processes but usually complicated and at times limited with large number of parameters needed On the other hand, Prediction of power output of a coalfired power plant by Quicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industry In the basic oxygen steelmaking (BOS) process, quicklime Quicklime Preparation, Properties, and Applications with FAQs

.jpg)

Coal power in the United States Wikipedia

Plant Bowen, the third largest coalfired power station in the United States Sources of electricity for 2016 [1] Coal electrical generation (black line), compared to other sources, 1949–2016 Coal power generation in 2011 by state Coal generated about 195% of the electricity at utilityscale facilities in the United States in 2022, down from 386% in 2014 [2] and 51% in 2001 [3]2021年12月6日 In Germany, for instance, the costs for redispatching (with countertrading), feedin management, and grid reserve power plants 14 (see Table 1) in 2017 (EUR 1511 million, 26 103 GWh) 15 increased by 69% compared to 2016 (EUR 894 million, 16 427 GWh), 15 mainly caused by delays in transmission grid expansion plus weak winds in 2016 16, 17 and strong Minimum loads of coal‐fired power plants and the potential A coalfired power plant (Fig 2) operates by burning coal to generate heat, which is then used to produce steam in a boilerThe highpressure steam drives turbines connected to generators, converting the kinetic energy into electricity Coalfired power plants have long been prominent in electricity generation due to the abundant availability of coal reservesCoalFired Thermal Power Plant ScienceDirect Topics2023年5月11日 International Atomic Energy Agency Vienna International Centre, PO Box 100 A1400 Vienna, Austria Telephone: +43 (1) 26000, Facsimile +43 (1) 26007Infographics: Nuclear Energy Compared IAEA

Mapped: The world’s coal power plants in 2020 Carbon Brief

2020年3月26日 The number of plants newly under construction each year is falling even faster, down 66% in 2019 compared to 2015, according to the latest annual status report from Global Energy Monitor Meanwhile, coal retirements are at historically unprecedented levels, with the 34GW of closures in 2019 a close third behind 2015 (37GW) and 2018 (35GW)