Development Trend of Talc Powder Equipment Raymond Mill

Raymond® Roller Mills Coperion

The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and othersThe development of 3 to 5 years of new mill equipment high pressure mill will become a trend or even completely replace the Raymond millThe development trend of Raymond Mill in powder industryThe Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specifications It is an efficient fine grinding Raymond Mill2021年10月21日 Raymond mill is the main equipment for grinding in China's powder industry In order to meet the requirements of different application fields, it is an inevitable trend to develop The development trend of Raymond Roller Mill

The application and development trend of talc powder

For example, the reinforcement of ABS through glass fiber, metal fiber and wood fiber makes the composite material suitable for 3D fused deposition process; powdered plastic is usually sintered by laser, which can be modified by 2018年8月7日 Raymond mill is the main equipment for grinding in the powder industry In order to meet the requirements of different application fields, it is an inevitable trend to developRaymond Mill's three major directions for future developmentThe Raymond mill, also known as the Raymond roller mill, is a type of stone grinder that utilizes a combination of impact, pressure, and friction to reduce talc ore into fine powder It is renowned The Finely Produced Raymond Mill: A Premier Choice for Talc 2020年6月16日 Raymond mill has been widely used in highfine pulverization processing of nonflammable and nonexplosive materials, such as quartz, talc, marble, limestone, dolomite, 4 steps to help you understanding the Raymond Mill

.jpg)

Evolution and Development Trend Prospect of Metal Milling

2023年3月10日 To better grasp the development direction of advanced manufacturing equipment, the development process and current application status of manufacturing 2019年5月22日 For Raymond mill's investment, we often expect a small investment and big return, so understanding the capacity and quality of the equipment is only one part of it, and we need to understand the what is the application of raymond mill LinkedInThere are many kinds of talc powder making machines, such as: talc Raymond mill, talc ball mill, talc vertical roller mill and talc micro powder grinding millSure, there also have lots of difference between there four types of talc powder making machine Talc Raymond Mill and Talc Vertical Roller Mill Both of them are high efficiency talc powder making machines, and both of them 4 Types of Talc Powder Making Machine clirik ultrafine grinding millThe Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation SBM has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Mill, MTW European Grinding Mill Raymond Mill History, Working Principle Applications

.jpg)

News Application of Talc Raymond Mill In The Production

Mix the magnetically separated talc powder with appropriate amount of water, mix the slurry and hydrochloric acid with 20% mass concentration of 1030% crude talc powder, stir evenly until no bubbles are produced on the liquid surface, filter, wash with water until the washing solution is neutral, and then flotation refining; Add proper amount of water to the acidwashed talc powder Raymond mill is mainly used for fine grinding various ores, feldspar, calcite, talc, barite, fluorite, rare earth, marble, bauxite, manganese ore, iron ore, copper ore, slag, granite We support providing complete powder grinding plant equipment, including cyclone powder collector, dust collector, bucket elevator, vibrating feeder, Raymond Mill JXSC MachineryNew Generation of Large Powder Grinding Mill, large powdermaking equipment Fineness: 0180038mm Following the powdermaking development trends, HC1700 grinding mill, with revolutionary and innovative technology, is designed by our engineers who devote great effect to improving the structure and capacity of traditional Raymond MillHC1700 Grinding Mill, Raymond Roller Mill, Pendulum Roller MillRaymond Mill Raymond mill is suitable for preparation of various mineral powder and pulverized coal, also called high pressure roller mill After longterm research and development, Zenith has developed the upgrading products of Raymond mill MTM series medium speed trapezium mill and MTW series trapezium mill Feed Size: 035mmRaymond Mill, Raymond Mill Technical Innovation

Kaolin Raymond Mill SBM Ultrafine Powder Technology

Kaolin Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 135 t/h Materials: Raymond mill is used to process gypsum powder, talc powder, titanium dioxide powder, bone meal, shell powder, carbon black powder, coal powder, various rubber powder, alum and other chemical powdersAt 2021 Calcium Carbonate Industry Conference,CLIRIK highlighted two ultrafine Raymond mills that are widely acclaimed in the field of calcium carbonate powder processing: HGM ring roller micro powder grinding Raymond mill and CLUM ultrafiUltra Fine Raymond Mill Is The Future Of Calcium Carbonate Raymond mill , also known as raymond grinding mill, is designed to grind nonflammable and nonexplosive materials with Mohs hardness below 7 and humidity less than 6% into fine powder The machine is popular for its high output, fine particle size, and energy efficiencyThe versatile applications of raymond mill in powder production The company's main products are HGM series ultrafine grinding mill, YGM Raymond mill, CLUM vertical mill 80500 mesh andalusite powder Raymond mill; CLRM series Raymond mill; Barite Raymond mill; Dolomite Raymond Mill; Applied Materials 100+ material From fine and soft talc (MOH's hardness 1), gypsum (MOH's hardness 2) to hard potash Raymond millIndustrial Grinding Mill, Ultrafine Grinding Mill

FYEFEPS2HDZ49G5Z0[B.jpg)

What is the price of 200 mesh talc Raymond mill?

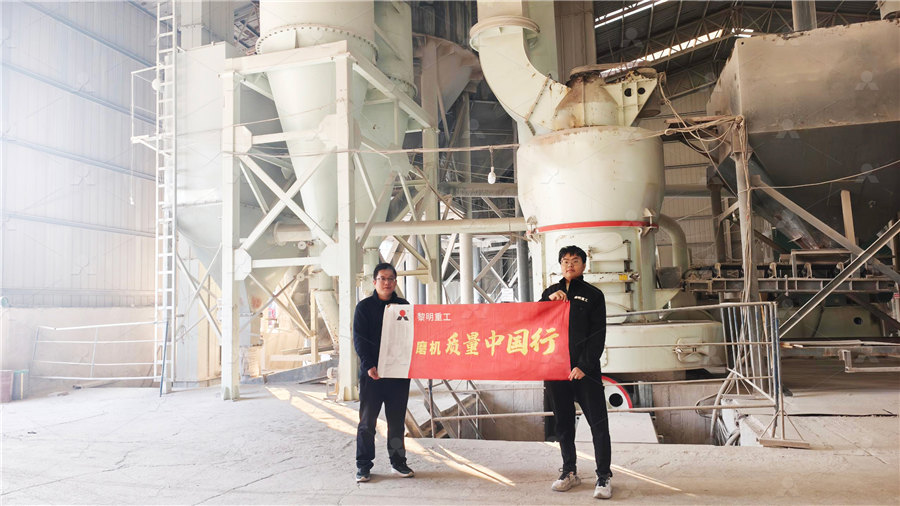

As we all know, 200 mesh talc powder is widely used in many field With the further development of industry, demand for talc powder is increasing According to this market trend, Liming Heavy Industry launched MTW Heavy type Trapezium Mill , an upgraded product of Raymond MillRaymond mill is a kind of mineral powder making equipment It has the characteristics of dry continuous grinding, centralized final particle size distribution, continuously adjustable fineness, and compact layout The particle size of automatic Four factors Affecting the Grinding Efficiency of Raymond Mill2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more environmentally friendly, and has a low investment 1503000 mesh calcium carbonate powder can use SBM calcium carbonate ultrafine grinding Calcium Carbonate Grinding Mill Powder Modify SBM Ultrafine Powder 2021年8月13日 The YGM Raymond grinding mill can be used to produce talc powder below 300 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more environmentally friendly, longer service life, and low investment 3003000 mesh talcum powder can use SBM ultrafine grinding millTalc Ultra Fine Powder Grinding Mill

.jpg)

Raymond Roller Grinding Mill Machine

2021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine It is widely applied in ore materials grinding Raymond mill is the key equipment of powder Talc is a kind of silicate mineral, belongs to trioctahedron mineral, the structural formula is (Mg6)[Si8]O20(OH)4 Talc generally in bar, leaf, fiber or radial pattern The material is soft and creamy The Mohr’s Hardness of talc is 115the use of talc talc grinding mill talc raymond mill hcm2023年3月10日 21 Origin and Early Development of the Machine Tools More than 2000 years ago, purely manual methods could no longer satisfy the daily production There was an arising demand for tools, then the first prototype of the machine tool, tree lathe, appeared, as shown in Figure 2a When using the lathe, users would step on the lower loop with their feet to drive the Evolution and Development Trend Prospect of Metal Milling EquipmentThe Raymond® Roller Mill is an Bentonite, Kaolin, Barytes, Gypsum, Limestone, Phosphate Rock, Talc, Coal, Hydrated Lime, Petroleum Coke, Pigments, Phenolic Resins or similar materials Gallery; Downloads; Brochures Raymond Roller Mill Upgrades (16590 kB) RBS Research Development Center (19618 kB) Raymond Guide to Quality Equipment Raymond® Roller Mills Coperion

Barite Raymond mill SBM Ultrafine Powder Technology

Raymond mill is a highefficiency pulverizing mill that replaces ball mill to process ore powderIt has outstanding advantages such as strong systematicness, concrete, etc Barite is widely distributed, and the barite grinding line is a promising development project Raymond flour mill is the core equipment for barite processing2021年7月9日 Dry grinding equipment includes impact mill, jet mill, vortex mill, vibration mill, stirring mill, and tower mill The principle of jet pulverization process of talc is: talc block→coarse crushing→drying→medium crushing→fine The processing and application of talc ALPA 2023年2月15日 Talc is finally used in the form of powder, so the purified talc needs to be crushed and ground Talc has a Mohs hardness of 1, which is naturally crushable and has good grindability It is commonly crushed by a jaw How to Process Talc (the Softest Mineral)? FTM In the mining equipment, there are many types of mill models, including different models and structural principles, respectively, for different user needs, production, etc, mainly including raymond mill equipment, limestone mill, ultrafine milling machines, centrifugal mills, air mills, etc, for different materials in different fields, the main industry sectors are mining, metallurgy What is the position of raymond mill in the ore industry and

.jpg)

Raymond Mill Fodamon Machinery

Introduction of Raymond Mill Raymond mill is widely used in the processing of 280 kinds of materials, such as dolomite, limestone, potash feldspar, barite, calcite, talc, marble, fluorite, activated clay, activated carbon, bentonite, kaolin, cement, gypsum, glass, etc, with Mohs hardness no more than 93 and humidity less than 6%The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY2024年2月23日 SBM micro powder technology leads the market, HGM ultrafine mill and YGM Raymond mill are selling well all over the country 23/02/2024 admin February 22, 2024 – With the rapid development of the economy, the demand for powder processing in various industries continues to growSBM micro powder technology leads the market, HGM ultrafine mill 2024年3月22日 The Raymond mill offers versatility in grinding as it can effectively process a diverse range of materials including limestone, gypsum, calcite, dolomite, barite, marble, talc, coal powder, and more This broad applicability makes it a valuable tool for various industries requiring finely ground materials for their processesHow Does a Raymond Roller Mill Work Raymond Grinding Mill

-2.jpg)

Micro Powder Grinding Mill

It is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Barite, gypsum, graphite, fluorite, phosphate rock, potassium ore, etc Micro powder grinding mill is double in capacity compare with Energy The Raymond mill, or Raymond roller mill, is an efficient, ecofriendly, closedcycle mill It integrates grinding, classification and drying (if necessary) to produce powders of precise sizes The Raymond mill is widely used in cement, chemicals, mining, construction, and Highefficient Raymond Mill Fote MachineryAs we all know, 150 mesh talc powder is widely used in many field With the further development of industry, demand for talc powder is increasing According to this market trend, Liming Heavy Industry launched MTW Heavy type Trapezium Mill, an upgraded product of Raymond Mill The advantage of MTW Heavy type Trapezium Mill:What is the price of 150 mesh talc Raymond mill?2019年5月22日 For Raymond mill's investment, we often expect a small investment and big return, so understanding the capacity and quality of the equipment is only one part of it, and we need to understand the what is the application of raymond mill LinkedIn

4 Types of Talc Powder Making Machine clirik ultrafine grinding mill

There are many kinds of talc powder making machines, such as: talc Raymond mill, talc ball mill, talc vertical roller mill and talc micro powder grinding millSure, there also have lots of difference between there four types of talc powder making machine Talc Raymond Mill and Talc Vertical Roller Mill Both of them are high efficiency talc powder making machines, and both of them The Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation SBM has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Mill, MTW European Grinding Mill Raymond Mill History, Working Principle ApplicationsMix the magnetically separated talc powder with appropriate amount of water, mix the slurry and hydrochloric acid with 20% mass concentration of 1030% crude talc powder, stir evenly until no bubbles are produced on the liquid surface, filter, wash with water until the washing solution is neutral, and then flotation refining; Add proper amount of water to the acidwashed talc powder News Application of Talc Raymond Mill In The Production Raymond mill is mainly used for fine grinding various ores, feldspar, calcite, talc, barite, fluorite, rare earth, marble, bauxite, manganese ore, iron ore, copper ore, slag, granite We support providing complete powder grinding plant equipment, including cyclone powder collector, dust collector, bucket elevator, vibrating feeder, Raymond Mill JXSC Machinery

HC1700 Grinding Mill, Raymond Roller Mill, Pendulum Roller Mill

New Generation of Large Powder Grinding Mill, large powdermaking equipment Fineness: 0180038mm Following the powdermaking development trends, HC1700 grinding mill, with revolutionary and innovative technology, is designed by our engineers who devote great effect to improving the structure and capacity of traditional Raymond MillRaymond Mill Raymond mill is suitable for preparation of various mineral powder and pulverized coal, also called high pressure roller mill After longterm research and development, Zenith has developed the upgrading products of Raymond mill MTM series medium speed trapezium mill and MTW series trapezium mill Feed Size: 035mmRaymond Mill, Raymond Mill Technical InnovationKaolin Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 135 t/h Materials: Raymond mill is used to process gypsum powder, talc powder, titanium dioxide powder, bone meal, shell powder, carbon black powder, coal powder, various rubber powder, alum and other chemical powdersKaolin Raymond Mill SBM Ultrafine Powder TechnologyAt 2021 Calcium Carbonate Industry Conference,CLIRIK highlighted two ultrafine Raymond mills that are widely acclaimed in the field of calcium carbonate powder processing: HGM ring roller micro powder grinding Raymond mill and CLUM ultrafiUltra Fine Raymond Mill Is The Future Of Calcium Carbonate

.jpg)

The versatile applications of raymond mill in powder production

Raymond mill , also known as raymond grinding mill, is designed to grind nonflammable and nonexplosive materials with Mohs hardness below 7 and humidity less than 6% into fine powder The machine is popular for its high output, fine particle size, and energy efficiency