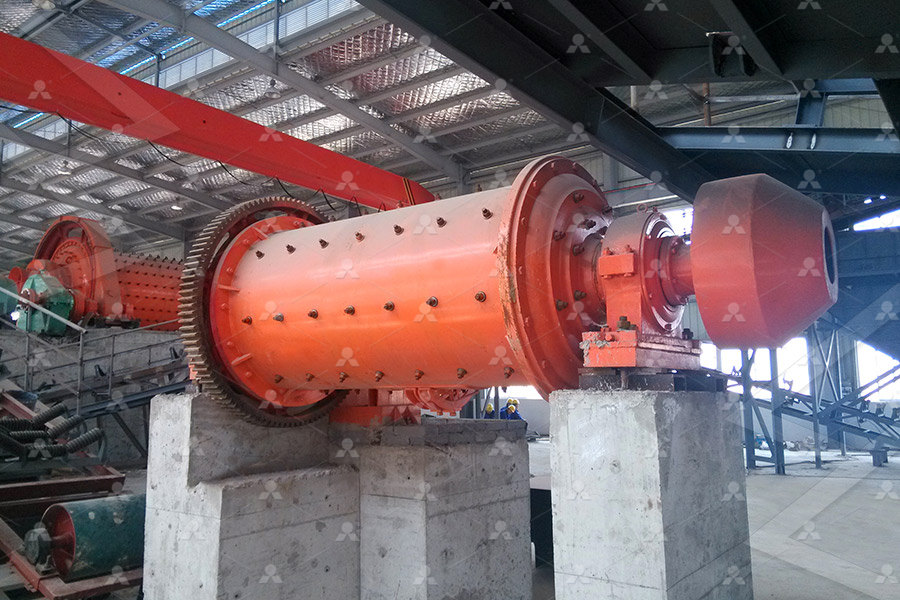

Tire cracking carbon black grinding production line grinding equipment

Tire pyrolysis carbon black deep processing grinding

2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill HGM series carbon black grinding mill adopts GCr15SiMn for Ring and Roller, which is better than normal 60Si2Mn So far, it is good at waste tyre pyrolysis carbon black micron powder making carbon black processing machine, tyre pyrolysis carbon black 2023年4月25日 The ultrafine ring roller mill can be used in the 3060 tons per day tire cracking and fine grinding production line After processing by the grinding equipment, it can produce Tire cracking and fine grinding production line equipmentSpecially, after several years of research and testing, we have a mature carbon black production line The carbon black production line includes carbon black pyrolysis plant, tyre pyrolysis carbon black processing machine, tyre pyrolysis carbon black

Carbon black powder grinding mill LIMING HEAVY INDUSTRY

Waste tires are broken into 020mm fragments by shredders, and then enter cracking furnaces Through hightemperature cracking, the tires are split into oil gas, and carbon black The Application field:One part of carbon black production line, to collect the carbon black powder Type:dust cleaner of carbon black processing machine Capacity:1100t/h Live Chat Activated carbon black processing machine, tyre pyrolysis carbon black 2023年9月19日 Refined carbon black after cracking of waste tires 1 Refined carbon black is reused to make car tires, fan belts and printer toner 2 Regenerated carbon black can be HGM80 Ultra Fine Grinding Mill Used in Waste Tire Powder Whether looking to produce carbon black from biomass, transform it into biochar or activated carbon, or recover it from waste tires, FEECO custom rotary kilns provide an ideal thermal processing environmentCarbon Black Processing Equipment FEECO

2T/H Tire Pyrolysis Carbon Black ProjectLIMING HEAVY

2T/H Tire Pyrolysis Carbon Black Project Equipment: MW1080 Material: carbon black after tire pyrolysis Capacity: 152t/h Output size: D99 400600 mesh Location: Atlanta, USA Using step 2: pyrolysis carbon black grinding mill production linecarbon black grinding mill Shanghai Clirik Machinery has been in this field over 8 years, designed and produced HGM carbon black grinding mill, which are best for carbon black micro powder processing 1carbon black processing machine, tyre pyrolysis carbon black grinding 2023年8月17日 Carbon Black Grinding Mill Equipment [] 1about carbon black grinding mill 11 the importance of carbon black grinding mill 12 carbon black grinding mill applicationcarbon black processing machine, tyre pyrolysis carbon black grinding The pyrolysis treatment of waste tires is the most thorough and effective way to recycle rubber resources Pyrolysis carbon black, as one of the pyrolysis products, accounts for about 30%35% of the total pyrolysis productsWaste Tire Cracking Carbon Black Equipment

.jpg)

carbon black processing machine, tyre pyrolysis carbon black grinding

Shanghai Clirik Machinery devoted to provide carbon black processing and grinding solution, carbon black processing machine, tyre pyrolysis carbon black grinding, carbon black production line, carbon black grinding mill, carbon black grinder mill for saleSpecially, after several years of research and testing, we have a mature carbon black production line The carbon black production line includes carbon black pyrolysis plant, tyre pyrolysis carbon black grinding, carbon black refining equipment, carbon black grinding mill, carbon black pellet making machine, carbon black briquetting machine, oil distillation machine, etccarbon black processing machine, tyre pyrolysis carbon black grinding The production capacity of a single production line is usually less than 3 tons per hour, main processes include shredding and separation Rubber blocks (size can be customized), steel wires and fabrics can be separated Optional equipment includes granulators, rubber breakers and grinders, cracking equipment, dust removal and other equipmentWaste Tire Shredding Recycling System GEP ECOTECH2022年9月30日 4 Global Recycled Carbon Black (rCB) Market Size Global Recycled Carbon Black (rCB) Market Size Growth Expected at a CAGR of 4381% from 2018 to 2024 The recovered carbon black (rCB) industry was valued at USD 5566 million in 2018 and is expected to reach USD 4923 million by 2024, growing at a CAGR (CAGR) of 4381% between 2018 Recovered Carbon Black rCB Processing Grinding Mill Machines

Carbon black production process and equipment selection

About Carbon Black Carbon black is a black powdered form of amorphous carbon Carbon black is formed by the accumulation of spheroidal or chain particles with an average diameter of 2~3nm, and contains a microcrystalline structure with a diameter of 3~500nm, which can react with various free radical2023年12月14日 In 2018, a Turkish customer contacted SBMmill for the first time as a middleman and purchased equipment for the grinding link in the cracked carbon black production line and exported it to South Korea Based on specific needs, SBMmill selected the star product in the HGM series: Türkiye Pyrolysis Carbon Black Grinding Line Project ReviewCarbon black is an amorphous carbon Light, loose and extremely fine black powder with very large specific surface area, ranging from 103000m2/g, which is obtained by incomplete combustion or thermal decomposition of organic matter (natural gas, heavy oil, fuel oil, etc) under the condition of insufficient air productWhat equipment is used in the carbon black grinding production line?2016年11月23日 The carbon black grinding machine is an ideal energysaving micropowder production equipment with excellent performance and efficiency Carbon Black Grinding Equipment The fine powder grinding machine is Introduction, Usage, and Characteristics of Carbon

.jpg)

Grinding mill for carbon black powder production

Carbon black ultrafine grinding equipment generally refers to the threering fourring superfine grinding machine The threering fourring ultrafine grinding machine adopts the grading continuous grinding method to carry out multiple cycles of grinding on the material at the same time, realizing ultrafine grinding2021年8月31日 Carbon black can be divided into three categories according to its purpose and characteristics: rubber carbon black, pigment carbon black and conductive carbon black Carbon black for rubber, such as tire manufacturing Carbon Black Ultrafine Powder MillThis production line is located in the United States Processing materials: carbon black after tire cracking Hourly output: 152t/hCarbon black grinding production line case #grindingmill2024年3月6日 cavitational vortex milling for carbon black valorization and highlight the tradeoffs associated with enhancing biofuel properties through the addition of rCB Keywords: tire pyrolysis; carbon black; recycling; contamination; cavitational vortex milling 1 Introduction Carbon black stands as a fundamental product within the chemical industry Recycling of LowQuality Carbon Black Produced by Tire Pyrolysis

.jpg)

(PDF) Production and Upgrading of Recovered Carbon Black

2022年3月9日 Production and Upgrading of Recovered Carbon Black from the Pyrolysis of EndofLife T ires Sebasti ã o M R Costa 1 , David Fowler 2 , Germano A Carreira 2 , In ê s Portugal 1, * and Carlos M Our company mainly produces fully automatic waste tire shredding and pyrolysising production lines, waste rubber pyrolysis equipment, waste plastic pyrolysis machine, and oil sludge pyrolysis machineAt the same time, our company integrates frontend processing, midrange cracking machine, and backend carbon black grinding and granulation,The entire production chain has quality carbon black grinding machineLongyuan BaihongPrimary particle size of carbon black is usually 10 – 500 nm of carbon super fine particles It is used for reinforcement of rubber, pigment and conductive materials Nearly 70% of carbon black product is used in tire manufacturing Carbon black is produced from the incomplete combustion of petroleum products such as oil and tarTire Carbon Black Hosokawa Micron MalaysiaCarbon black ultrafine grinding mill adopts a graded continuous grinding method to grind the material multiple times at the same time to truly realize ultrafine grinding +17 [ protected] language pic of production line; equipment of production line;Carbon Black Ultrafine Grinding Mill

.jpg)

Efficient Fine Grinding of Recovered Carbon Black with

This webinar gives an overview of the state of the art of jet milling technology Due to the parameters it will become clear that new technologies were required on a dynamic market Motivated out of this, NETZSCH developed two new systems The economic EJET® system and the superfine SJET® system which is operating with overheated steam It will be shown, that 2T/H Tire Pyrolysis Carbon Black Project Equipment: MW1080 Material: carbon black after tire pyrolysis Capacity: the company purchased our MW micro powder mill production line for processing carbon black after tire cracking Recommended Case Limestone sand powder preparation in India > 30 TPH limestone grinding production line in India2T/H Tire Pyrolysis Carbon Black ProjectLIMING HEAVY Carbon Black Ultrafine Powder Grinding Mill— Case In ChinaCarbon Black Ultrafine Powder Grinding Mill— Case In China2021年10月29日 News/Industry News/Magnesite Grinding Equipment Production Line Magnesite Grinding Equipment Production Line 29/10/2021 admin Carbon Black Ultrafine Powder Mill; Rock Powder Grinding Mill; Magnesite Grinding Equipment Production Line

carbon black grinding machine, carbon black grinding mill, carbon black

Carbon black, also known as carbon black, is an amorphous carbon Light, loose and very fine black powder with a very large surface area ranging from 10 to 3000 m2/g It is a carbonaceous material (coal, natural gas, heavy oil, fuel oil, etc) that undergoes incomplete combustion or thermal decomposition under conditions of insufficient ZSCH Trockenmahltechnik GmbH GD recovered Carbon Black EN 04/2019 Technical specifications are subject to change Rodenbacher Chaussee 1 63457 Hanau Germany Tel: +49 6181 50601 Fax: +49 6181 571 270 infontt@netzsch Business Unit Grinding Dispersing – The World’s Leading Grinding TechnologyProcess Technology for recovered Carbon Black (rCB) Grinding Among them, rubber carbon black, pigment carbon black and conductive carbon black are the most commonly used Carbon black grinding mill CLIRIK's HGM ultrafine grinding mill is suitable for processing carbon black powder The processing fineness ranges What is carbon black? What is the use of N220 N330 carbon black Introduction of the carbon black grinding machine The carbon black powder grinder machine produced by Beston Group is suitable for the grinding process of metallurgy, building materials, chemicals, mining and other minerals materials It can be used for powder processing various materials with Mohs hardness below 8 and humidity less than 6%, such as red mud, kaolin, Carbon Black Grinding Machine Beston Pyrolysis Plant

Carbon black grinding production line case #grindingmill

This production line is located in the United States Processing materials: carbon black after tire cracking Hourly output: 152t/hThe production process of carbon black includes furnace method, spray method, lamp smoke method, 2 sets Carbon black production; Carbon black production line i; NEWS SHOW 5 kinds of carbon black production processes Author : Thermal cracking carbon black is the carbon black variety with the largest particles and the lowest structure5 kinds of carbon black production processesIn the continuous technological breakthroughs, our company andQingdao University of Science and Technology have jointly established a laboratory and jointly developed waste tire pyrolysis carbon black equipment realized the intelligentization of Industry 40, and the factory changed from a large number of manual operations to automated productionTire Recycling Plant Manufacturer, Shredder, Carbon Black step 2: pyrolysis carbon black grinding mill production linecarbon black grinding mill Shanghai Clirik Machinery has been in this field over 8 years, designed and produced HGM carbon black grinding mill, which are best for carbon black micro powder processing 1carbon black processing machine, tyre pyrolysis carbon black grinding

.jpg)

carbon black processing machine, tyre pyrolysis carbon black grinding

2023年8月17日 Carbon Black Grinding Mill Equipment [] 1about carbon black grinding mill 11 the importance of carbon black grinding mill 12 carbon black grinding mill applicationThe pyrolysis treatment of waste tires is the most thorough and effective way to recycle rubber resources Pyrolysis carbon black, as one of the pyrolysis products, accounts for about 30%35% of the total pyrolysis productsWaste Tire Cracking Carbon Black EquipmentShanghai Clirik Machinery devoted to provide carbon black processing and grinding solution, carbon black processing machine, tyre pyrolysis carbon black grinding, carbon black production line, carbon black grinding mill, carbon black grinder mill for salecarbon black processing machine, tyre pyrolysis carbon black grinding Specially, after several years of research and testing, we have a mature carbon black production line The carbon black production line includes carbon black pyrolysis plant, tyre pyrolysis carbon black grinding, carbon black refining equipment, carbon black grinding mill, carbon black pellet making machine, carbon black briquetting machine, oil distillation machine, etccarbon black processing machine, tyre pyrolysis carbon black grinding

Waste Tire Shredding Recycling System GEP ECOTECH

The production capacity of a single production line is usually less than 3 tons per hour, main processes include shredding and separation Rubber blocks (size can be customized), steel wires and fabrics can be separated Optional equipment includes granulators, rubber breakers and grinders, cracking equipment, dust removal and other equipment2022年9月30日 4 Global Recycled Carbon Black (rCB) Market Size Global Recycled Carbon Black (rCB) Market Size Growth Expected at a CAGR of 4381% from 2018 to 2024 The recovered carbon black (rCB) industry was valued at USD 5566 million in 2018 and is expected to reach USD 4923 million by 2024, growing at a CAGR (CAGR) of 4381% between 2018 Recovered Carbon Black rCB Processing Grinding Mill MachinesAbout Carbon Black Carbon black is a black powdered form of amorphous carbon Carbon black is formed by the accumulation of spheroidal or chain particles with an average diameter of 2~3nm, and contains a microcrystalline structure with a diameter of 3~500nm, which can react with various free radicalCarbon black production process and equipment selection2023年12月14日 In 2018, a Turkish customer contacted SBMmill for the first time as a middleman and purchased equipment for the grinding link in the cracked carbon black production line and exported it to South Korea Based on specific needs, SBMmill selected the star product in the HGM series: Türkiye Pyrolysis Carbon Black Grinding Line Project Review

.jpg)

What equipment is used in the carbon black grinding production line?

Carbon black is an amorphous carbon Light, loose and extremely fine black powder with very large specific surface area, ranging from 103000m2/g, which is obtained by incomplete combustion or thermal decomposition of organic matter (natural gas, heavy oil, fuel oil, etc) under the condition of insufficient air product